The Evolution of Solar Energy: Understanding AC Micro Inverters

The global transition towards sustainable energy sources has dramatically accelerated, with solar photovoltaic (PV) systems at the forefront. As demand for efficient, reliable, and scalable solar solutions grows, technological advancements continue to redefine the landscape. Among the most impactful innovations is the ac micro inverter. Unlike traditional string inverters, which convert DC electricity from an entire array into AC power at a central point, microinverters operate at the individual solar panel level. This fundamental shift offers profound advantages in terms of performance optimization, system reliability, and operational safety, making them increasingly the preferred choice for a diverse range of solar installations, from residential rooftops to sophisticated commercial arrays. The inherent flexibility and resilience of a micro inverter system are critical drivers behind its growing adoption across various industries.

This detailed exploration delves into the core aspects of AC micro inverter technology, covering its underlying principles, manufacturing processes, key technical specifications, and diverse application scenarios. We will also examine its compelling technical advantages, provide a comprehensive vendor comparison, discuss the possibilities of customized solutions, and present compelling real-world application case studies. Our aim is to provide B2B decision-makers and technical engineers with an authoritative and trustworthy resource for understanding and leveraging this transformative technology.

Industry Trends and Market Dynamics for Solar Microinverters

The market for microinverter technology is experiencing robust growth, driven by several key macro and micro-economic factors. Globally, the push for decarbonization and energy independence has led to significant government incentives and policy support for renewable energy, directly bolstering the solar sector. Within solar PV, there's a discernible shift towards distributed generation and grid-edge solutions, where microinverters excel due to their modularity and ability to optimize energy harvest even in challenging conditions.

Recent industry reports indicate a Compound Annual Growth Rate (CAGR) exceeding 15% for the global microinverter market, projected to reach over $7 billion by 2028. This growth is fueled by increasing residential and commercial solar installations, rising awareness of energy efficiency, and the undeniable advantages in system performance and safety offered by individual module-level power electronics (MLPE). Emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid adoption rates as they build out new energy infrastructures. Furthermore, the integration of smart grid technologies and energy storage solutions creates a synergistic environment for advanced solar microinverter systems, enhancing their value proposition for modern power grids. The continuous innovation in power electronics, materials science, and digital monitoring platforms further solidifies the position of microinverters as a leading-edge solution in the renewable energy domain, often included as part of a comprehensive micro inverter solar kit.

The Advanced Manufacturing Process of AC Micro Inverter

The production of a high-performance ac micro inverter is a sophisticated process that integrates advanced engineering, precision manufacturing, and rigorous quality control. This multi-stage process ensures that each unit meets stringent performance, durability, and safety standards required for long-term outdoor operation. The focus on quality materials and robust manufacturing techniques is paramount, given the expected service life often exceeding 25 years.

1. Material Sourcing and Component Fabrication:

- Electronic Components: High-grade silicon carbide (SiC) or gallium nitride (GaN) power semiconductors are selected for their superior efficiency and thermal performance. Control chips, capacitors, and magnetics are sourced from reputable suppliers, often requiring ISO 9001 certification.

- Enclosure Materials: For optimal corrosion resistance and thermal dissipation, marine-grade aluminum alloys (e.g., 6061-T6) are commonly utilized. These materials undergo precision CNC machining or die-casting processes to achieve exact dimensions and smooth finishes for environmental sealing.

- Wiring and Connectors: UV-resistant, outdoor-rated cabling with IP67 or IP68 rated connectors (e.g., MC4 compatible) ensures long-term electrical integrity and environmental protection.

2. Printed Circuit Board (PCB) Assembly:

- Automated SMT: Surface Mount Technology (SMT) lines precisely place thousands of miniature components onto the PCBs. This highly automated process minimizes human error and ensures consistency.

- Reflow Soldering: Controlled reflow ovens bond components to the PCB using lead-free solder alloys.

- Automated Optical Inspection (AOI): Post-soldering, AOI systems scan each board for defects, missing components, or incorrect placement.

3. Final Assembly and Encapsulation:

- Module Integration: The assembled PCB is integrated into the pre-fabricated aluminum enclosure. Thermal interface materials (TIMs) are strategically applied to ensure efficient heat transfer from power electronics to the enclosure's heatsink fins.

- Potting and Sealing: Critical electronic components are often encapsulated or "potted" with a thermally conductive, electrically insulating epoxy resin. This provides superior protection against moisture, dust, vibration, and extreme temperature fluctuations, extending the service life and ensuring corrosion resistance. Gaskets and sealants are applied to achieve high ingress protection (IP) ratings, typically IP67 or IP68.

4. Rigorous Testing and Quality Assurance:

- Functional Testing: Each unit undergoes comprehensive electrical testing, including input DC voltage range, output AC power quality, maximum power point tracking (MPPT) accuracy, and efficiency validation across various load conditions.

- Environmental Stress Testing: Products are subjected to accelerated life testing, including thermal cycling, humidity exposure, salt mist corrosion testing (per ISO 9227), and vibration analysis.

- Safety and Compliance Testing: Compliance with international standards such as UL 1741, IEC 62109, and various grid codes (e.g., IEEE 1547, VDE AR-N 4105) is verified. This ensures operational safety, grid compatibility, and protection against overvoltage, overcurrent, and islanding.

- Automated End-of-Line Testing: Final calibration, firmware loading, and performance data logging occur before packaging.

Through these meticulous steps, manufacturers ensure that each ac micro inverter delivers exceptional performance, reliability, and longevity, often exceeding its projected 25-year service life in target industries such as residential energy, commercial facilities, and even specialized applications requiring high reliability and energy saving capabilities. The emphasis on robust materials and validated processes is key to achieving optimal energy harvesting and operational stability for any micro inverter system.

Technical Specifications and Performance Parameters for Microinverters

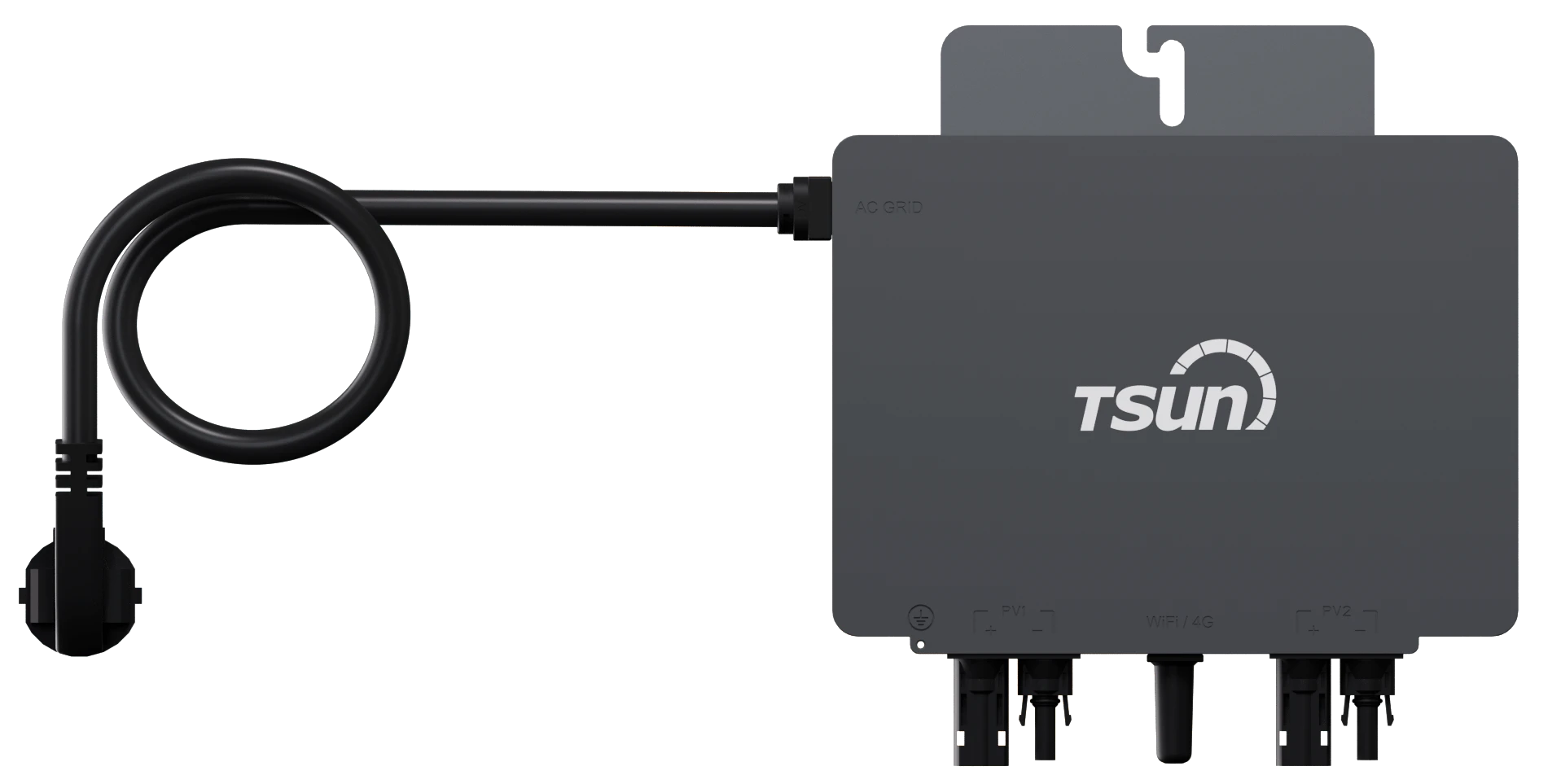

Understanding the technical specifications of an ac micro inverter is crucial for system designers and procurement specialists. These parameters define the inverter's compatibility with various PV modules, its efficiency under different operating conditions, and its overall robustness. Here, we present typical specifications for a high-quality 2-in-1 Microinverter, which supports two PV modules per unit, optimizing installation and wiring for a comprehensive micro inverter system.

Key Specifications for a 2-in-1 Microinverter (TSUN MS800/MS1000)

| Parameter |

Value/Description |

| Model |

TSUN MS800/MS1000 |

| Recommended PV Module Power |

Up to 550W+ (per module) |

| Maximum Input DC Voltage |

60V |

| MPPT Voltage Range |

20V - 55V |

| Maximum Input Current |

2 x 18A |

| Rated Output AC Power |

800VA / 1000VA |

| Nominal Output Voltage |

230V AC (configurable for various grids) |

| Nominal Output Frequency |

50Hz / 60Hz |

| Peak Efficiency |

97.5% |

| CEC Weighted Efficiency |

97.0% |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 |

| Communication |

Wi-Fi / ZigBee (optional) |

| Warranty |

10-25 Years (product dependent) |

These specifications highlight several critical performance metrics. The high peak and weighted efficiencies demonstrate minimal energy loss during conversion, directly impacting the overall yield of the solar microinverter system. The wide MPPT voltage range ensures optimal energy harvesting from PV modules even under varying irradiance or temperature conditions. Furthermore, the robust operating temperature range and IP67 enclosure rating guarantee reliable operation in harsh environmental conditions, critical for long-term outdoor deployment of any solar micro inverter kit.

Versatile Application Scenarios for AC Micro Inverter Systems

The inherent flexibility and modularity of ac micro inverter technology make it exceptionally well-suited for a broad spectrum of application scenarios. From dense urban residential environments to sprawling commercial and industrial complexes, microinverters provide tailored solutions that maximize energy yield, enhance safety, and simplify system design and expansion.

1. Residential Rooftop Installations:

- Partial Shading Optimization: Homes often face challenges with trees, chimneys, or adjacent buildings causing partial shading at different times of the day. Microinverters ensure that a shaded panel does not reduce the output of the entire array, as each panel operates independently, maintaining optimal performance for the rest of the solar microinverter kit.

- Complex Rooflines: Irregular roof shapes and multiple orientations are common. Microinverters allow panels to be installed at different angles and orientations without efficiency penalties, maximizing available roof space and energy generation.

- Enhanced Safety: With only low-voltage DC at the panel level and AC wiring running across the roof, the risk of high-voltage DC arcs, a primary cause of solar fires, is virtually eliminated. This is a significant advantage for homeowners.

- Scalability: Homeowners can start with a smaller system and easily expand it later by adding more panels and microinverters as their energy needs grow or budgets allow, without overhauling the existing micro inverter system.

2. Commercial and Industrial (C&I) Buildings:

- Large-Scale Flexibility: Commercial rooftops often feature numerous obstructions (HVAC units, vents). Microinverters facilitate flexible panel layouts to navigate these obstacles, ensuring maximum utilization of roof area.

- Improved Monitoring and Maintenance: Granular, module-level monitoring allows facility managers to quickly identify and troubleshoot underperforming panels, reducing O&M costs and downtime for the entire solar microinverter system.

- Energy Security and Resilience: For critical infrastructure, the distributed nature of microinverters means a single point of failure does not disable the entire system, enhancing energy resilience.

3. Specialized and Off-Grid Applications:

- Remote Power Systems: For remote cabins, communication towers, or monitoring stations where grid connection is unfeasible, microinverters integrate seamlessly with battery storage, offering robust and efficient power generation.

- Agricultural Settings: Pumping water for irrigation, powering remote sensing equipment, or providing electricity for farm buildings benefit from the reliability and durability of microinverters, especially in harsh outdoor conditions.

- EV Charging Infrastructure: Integrating solar microinverter kits directly into EV charging stations provides a sustainable and efficient power source, supporting the growth of green transportation.

The ability of microinverters to deliver energy savings, enhance system reliability through corrosion resistance, and simplify installation across such diverse scenarios underscores their value proposition. Their decentralized architecture is particularly advantageous for applications requiring high fault tolerance and consistent energy output, establishing them as a cornerstone of modern solar solutions.

Image: A high-efficiency TSUN 2-in-1 ac micro inverter, illustrating its compact design and robust build for diverse solar installations.

Technical Advantages of AC Micro Inverter Systems

The architectural difference of ac micro inverter technology compared to string inverters translates into a multitude of technical advantages that directly benefit system performance, safety, and long-term return on investment.

1. Module-Level Maximum Power Point Tracking (MPPT):

Each microinverter is coupled with an individual PV module, enabling independent MPPT for every panel. This ensures that each module operates at its peak power output regardless of the performance of other modules. In contrast, string inverters apply a single MPPT algorithm across an entire series of panels. This module-level optimization is particularly critical in scenarios involving partial shading, module mismatches (due to manufacturing tolerances or aging), or varying panel orientations. Studies have shown that module-level MPPT can increase overall system energy yield by 5% to 25% compared to string inverter systems in shaded or complex installations.

2. Enhanced Safety Features:

One of the most significant advantages of microinverters is their inherent safety. Traditional string inverters operate with high DC voltages (up to 1000V or more) running across the roof and into the building. Microinverters convert DC to AC directly at the panel, meaning only standard AC household voltage runs from the roof into the electrical panel. This dramatically reduces the risk of high-voltage DC arc faults, which are a common cause of electrical fires in solar installations. This enhanced safety profile is often a key driver for regulatory bodies and insurance providers, making solar microinverters a preferred choice for residential and commercial applications.

3. Superior Reliability and Redundancy:

With a string inverter, the failure of a single inverter can lead to the complete shutdown of the entire solar array. Microinverter systems, by contrast, offer built-in redundancy. If one microinverter fails, only the associated panel's output is affected; the rest of the solar microinverter kit continues to operate normally. This distributed architecture significantly enhances system reliability and uptime, minimizing energy production losses and making troubleshooting easier. Furthermore, many modern microinverters boast an average Mean Time Between Failures (MTBF) exceeding 500,000 hours.

4. Simplified Design and Scalability:

Designing a solar system with microinverters is inherently simpler. There are fewer design constraints regarding string sizing (matching voltage and current) and orientation, allowing for maximum flexibility in array layout. Expansion is also straightforward: additional panels and microinverters can be seamlessly integrated into an existing micro inverter system without affecting the performance of the original installation. This plug-and-play capability reduces installation time and costs.

5. Granular Monitoring and Diagnostics:

Microinverters provide module-level performance data, offering unprecedented insight into the operation of each individual panel. This granular monitoring allows for precise fault detection, rapid troubleshooting, and optimized maintenance scheduling. Installers and system owners can quickly identify underperforming modules, diagnose issues such as soiling or shading, and address them proactively, ensuring sustained peak performance throughout the life of the system.

These combined technical advantages underscore why solar microinverters are becoming the preferred solution for sophisticated and resilient solar PV installations, providing unparalleled energy savings and operational efficiency, along with excellent corrosion resistance due to their robust design.

Vendor Comparison and Differentiation in the AC Micro Inverter Market

The market for ac micro inverter technology features several reputable manufacturers, each offering distinct features and differentiators. While core functionalities like module-level MPPT and AC conversion are universal, key aspects such as efficiency, reliability, warranty, communication protocols, and monitoring platforms can vary significantly. B2B decision-makers must consider these factors when evaluating potential suppliers for their solar microinverter kits.

Key Differentiators:

- Efficiency Ratings: While most reputable brands offer high efficiencies (e.g., >97% peak), small differences can accumulate over a system's lifespan. CEC Weighted Efficiency provides a more realistic performance metric under varying conditions.

- Durability and Environmental Rating: Look for IP67/IP68 ratings, indicating superior protection against dust and water immersion. Corrosion resistance (e.g., C5-M marine environment classification) is critical for coastal or industrial applications.

- Warranty and Service Life: Industry-leading warranties typically range from 10 to 25 years. A longer warranty reflects the manufacturer's confidence in product longevity and reliability.

- Communication and Monitoring: Proprietary vs. open protocols (e.g., ZigBee, Wi-Fi, PLC) and the sophistication of the monitoring portal (real-time data, fault alerts, reporting) are vital for operations and maintenance.

- Scalability and System Integration: Ease of adding new modules and compatibility with other balance-of-system components (e.g., battery storage, smart home systems) are important for future-proofing.

- Certifications: Adherence to global and regional safety and grid-code certifications (e.g., UL, TUV, VDE, CE) is non-negotiable for market acceptance and compliance.

Comparative Overview (Illustrative)

| Feature |

Vendor A (e.g., Leading Global Brand) |

TSUN (2-in-1 Microinverter) |

Vendor C (e.g., Emerging Regional Player) |

| Peak Efficiency |

97.8% |

97.5% |

96.5% |

| CEC Weighted Efficiency |

97.3% |

97.0% |

96.0% |

| Enclosure Rating |

IP67 |

IP67 |

IP65 |

| Standard Warranty |

25 Years |

10-25 Years |

10 Years |

| Module Inputs |

1 or 2 |

2 |

1 |

| Communication |

Proprietary Wireless |

Wi-Fi / ZigBee |

PLC |

| Grid Code Certs (Sample) |

UL 1741, VDE 0126 |

IEC 62109, VDE 4105, C10/11, AS4777 |

CE |

This comparison illustrates that while top-tier vendors offer robust solutions, products like the TSUN 2-in-1 Microinverter provide competitive efficiency, superior build quality with IP67 rating, and flexible communication options, positioning them as an excellent choice for a reliable micro inverter system. When considering a vendor, it's essential to evaluate not just the product specifications, but also the manufacturer's track record, customer support infrastructure, and commitment to long-term partnerships.

Customized Solutions for Diverse Solar Microinverter Systems

In the B2B solar market, one-size-fits-all solutions are rarely optimal. Customization plays a pivotal role in maximizing efficiency, ensuring seamless integration, and meeting the specific operational and budgetary requirements of diverse clients. Manufacturers of solar microinverter systems recognize this need, offering a range of customization options from electrical parameters to software integration and physical form factors.

Areas of Customization:

- Voltage and Frequency Configuration: While standard units support common grid voltages (e.g., 230V AC) and frequencies (50/60Hz), specific regions or unique industrial applications may require precise voltage or frequency adjustments to align with local grid codes or specialized equipment.

- Communication Protocols: Integration into existing building management systems (BMS) or energy management systems (EMS) often requires support for specific communication protocols (e.g., Modbus RTU/TCP, BACnet, ZigBee, Wi-Fi). Custom firmware or hardware modules can be developed to ensure interoperability for a cohesive micro inverter system.

- Mechanical Design and Mounting: For unique architectural constraints or extreme environmental conditions (e.g., high vibration, corrosive atmospheres in petrochemical facilities), custom enclosure designs, mounting brackets, or specialized finishes (e.g., thicker powder coating for enhanced corrosion resistance) can be provided.

- Software and Monitoring Portal: White-labeling of monitoring platforms, integration with proprietary data analytics tools, or development of custom APIs allows clients to incorporate microinverter data seamlessly into their operational dashboards.

- Cable Lengths and Connector Types: Custom cable lengths for AC trunks or specialized DC connector types can optimize installation efficiency and reduce material waste, particularly for large-scale micro inverter solar kit deployments.

- Certification Adaptation: For projects in countries with nascent or unique solar regulations, manufacturers can undertake specific certification processes to ensure local compliance.

Engaging with a manufacturer that offers robust engineering support and flexible production capabilities is crucial for successful customization. For instance, TSUN’s technical team works closely with clients to understand precise project requirements, providing CAD designs, electrical schematics, and prototype development to ensure the customized solution meets all performance and compliance criteria. This collaborative approach ensures that the final solar microinverter system is not just installed, but perfectly optimized for its intended environment and operational goals, offering maximum energy saving potential and prolonged service life even in challenging industries like metallurgy or water supply & drainage.

Real-World Application Case Studies: Proving Micro Inverter Value

The practical benefits of microinverter technology are best illustrated through real-world applications where these systems have demonstrably outperformed traditional solutions and delivered significant value. These case studies highlight the versatility, reliability, and economic advantages of solar microinverters across various sectors.

Case Study 1: Urban Commercial Office Building, Germany

- Challenge: A multi-story office building in a densely populated urban area required a solar PV system to offset energy costs and achieve sustainability targets. The roof had numerous obstructions (HVAC units, skylights) causing significant partial shading at different times of day, making a traditional string inverter system inefficient.

- Solution: A 150 kWp microinverter system utilizing TSUN 2-in-1 microinverters was installed. The modular design allowed for flexible placement of 500 panels around the obstructions, maximizing the usable roof area. Each panel was equipped with its own MPPT, ensuring optimal energy harvest despite shading.

- Outcome: The system achieved an annual energy yield 18% higher than initial simulations for a comparable string inverter system. Module-level monitoring allowed facility managers to pinpoint and resolve minor performance issues quickly, maintaining high uptime. The enhanced safety features were a key factor in securing local building permits and reducing insurance premiums. This micro inverter system provided substantial energy savings and a demonstrable return on investment within 6 years.

Case Study 2: Coastal Residential Development, Australia

- Challenge: A new residential development near the Australian coast needed robust micro inverter solar kit for 50 homes. The harsh marine environment (salt mist, high humidity) posed a significant challenge for inverter durability and corrosion resistance. Complex roof architectures and varied shading patterns were also present.

- Solution: Each home was fitted with a 6-8 kWp solar microinverter system using microinverters featuring IP67 ingress protection and C5-M anti-corrosion ratings. The decentralized design accommodated varying roof orientations and minimized the impact of shading from neighboring houses or architectural elements.

- Outcome: After three years of operation, the systems have demonstrated exceptional resilience to the coastal environment with no reported corrosion-related failures. The modular design facilitated rapid installation, and homeowners reported significant energy bill reductions. Customer feedback consistently highlights the peace of mind provided by the system’s safety features (low DC voltage). The project developer noted a streamlined installation process and reduced post-installation service calls due to the inherent reliability of the micro inverter system.

Case Study 3: Remote Agricultural Pumping Station, India

- Challenge: An agricultural community in a remote part of India required a reliable and low-maintenance power source for an irrigation pumping station. Grid access was unreliable, and traditional diesel generators were costly to fuel and maintain.

- Solution: A standalone 10 kWp solar microinverter system was designed, paired with battery storage. The microinverters were chosen for their robust design and ability to operate efficiently even with occasional dust accumulation on panels, which would disproportionately affect a string inverter.

- Outcome: The pumping station now operates entirely on solar power, providing consistent irrigation without fuel costs. The system's decentralized nature ensured continued operation even if one panel's performance was temporarily compromised. Local technicians were easily trained on the simple module-level diagnostics, minimizing expert intervention. This project delivered critical energy independence and substantial long-term energy savings for the community.

These case studies underscore the tangible benefits of investing in a high-quality microinverter solution. From optimizing energy yield in complex urban settings to ensuring reliability in harsh coastal or remote environments, microinverters consistently prove their value by enhancing performance, safety, and operational efficiency across a broad spectrum of applications.

Ensuring Trust and Reliability: Quality, Certifications, and Support

For B2B clients, the decision to invest in a solar microinverter system hinges not just on technical specifications, but profoundly on the trust and reliability associated with the vendor and product. This encompasses robust quality assurance, adherence to international standards, comprehensive warranty commitments, and accessible customer support. A professional supplier understands that a partnership extends far beyond the point of sale.

Authoritative Certifications and Quality Assurance:

- ISO 9001 & ISO 14001: Manufacturers should operate under ISO 9001 certified quality management systems and ISO 14001 environmental management systems, demonstrating a commitment to consistent quality and sustainable practices.

- Product Certifications: Essential safety and grid-compliance certifications include UL 1741 (North America), IEC 62109 (International Safety Standard for Power Converters), VDE AR-N 4105 (Germany), C10/11 (Belgium), AS4777 (Australia), and CE marking (Europe). These certify that the product meets rigorous electrical safety, electromagnetic compatibility (EMC), and grid interconnection requirements, ensuring confidence in any micro inverter system.

- Reliability Testing: Products should undergo extensive accelerated life testing (ALT), Highly Accelerated Life Testing (HALT), and Highly Accelerated Stress Screening (HASS) to validate their operational longevity and performance in extreme conditions. Test reports and data should be available upon request.

- Partner Clients: A strong portfolio of successful projects with reputable clients and years of service in the industry are key indicators of a vendor's authority and proven track record.

Warranty Commitments:

A robust warranty is a cornerstone of trust. Reputable microinverter manufacturers offer product warranties typically ranging from 10 to 25 years, aligning with the expected lifespan of solar PV modules. This comprehensive warranty covers material defects and workmanship, providing long-term peace of mind for system owners. Details regarding warranty claims process, replacement procedures, and associated logistics should be clearly articulated for any micro inverter solar kit.

Customer Support and After-Sales Service:

- Technical Support: Access to experienced technical engineers for installation guidance, troubleshooting, and system optimization is paramount. Multi-channel support (phone, email, online portal) ensures timely assistance.

- Training Programs: Comprehensive training for installers and O&M teams on product installation, commissioning, and monitoring system usage builds capability and reduces field issues.

- Spare Parts Availability: Ensuring readily available spare parts and a clear process for returns and replacements minimizes downtime for any solar microinverter kit.

- Firmware Updates: Regular firmware updates that enhance performance, add features, or address security vulnerabilities demonstrate a commitment to ongoing product improvement.

By meticulously addressing these aspects, a manufacturer establishes a foundation of trustworthiness and expertise, assuring clients that their investment in a solar microinverter system is sound, reliable, and supported by a dedicated professional team for its entire service life.

Frequently Asked Questions (FAQ) about Microinverters

-

Q1: What is the primary difference between a microinverter and a string inverter?

A1: A microinverter is installed at each individual solar panel, converting DC electricity to AC power directly at the module level. A string inverter, conversely, handles the DC-to-AC conversion for an entire "string" or array of panels centrally. This fundamental difference gives microinverters advantages in terms of module-level optimization, enhanced safety (lower DC voltage on the roof), and system redundancy.

-

Q2: How do microinverters handle partial shading?

A2: Microinverters excel in partial shading conditions because each unit performs Maximum Power Point Tracking (MPPT) independently. If one panel is shaded, its output reduction does not affect the performance of the unshaded panels in the rest of the solar microinverter system, maximizing overall energy harvest. String inverters, by contrast, are more susceptible to the "Christmas light effect," where the weakest panel can drag down the performance of the entire string.

-

Q3: What are the safety benefits of using a solar microinverter system?

A3: The primary safety benefit is the elimination of high-voltage DC electricity on the rooftop. Microinverters convert DC to AC at the panel itself, meaning the wiring running from the roof into the building carries safe, standard AC voltage (typically 230V or 120V). This significantly reduces the risk of dangerous high-voltage DC arc faults and simplifies emergency response procedures for firefighters.

-

Q4: Are microinverters compatible with all solar panels?

A4: Generally, yes. Most microinverters are designed to be compatible with a wide range of standard PV modules. However, it's always crucial to check the microinverter's input voltage and current specifications against the PV module's electrical characteristics (Voc, Isc, Vmp, Imp) to ensure optimal performance and compatibility for a given micro inverter solar kit. TSUN 2-in-1 Microinverters, for example, are designed to work with PV modules up to 550W+.

-

Q5: What is the typical service life and warranty for microinverters?

A5: High-quality microinverters are designed for longevity, often with an expected service life exceeding 25 years, aligning with the lifespan of solar panels. Most reputable manufacturers offer a substantial product warranty, typically ranging from 10 to 25 years, reflecting their confidence in the durability and reliability of their solar microinverters.

Lead Time, Fulfillment, and Warranty Information

Understanding the logistical and financial commitments associated with procuring microinverter technology is essential for project planning and execution. Our commitment is to transparency and efficiency in all aspects of order fulfillment and post-sales support.

Lead Time and Fulfillment:

Standard lead times for our 2-in-1 Microinverter typically range from 4 to 6 weeks, depending on order volume and specific customization requirements. We maintain a strategic inventory of common models to facilitate quicker turnaround for urgent projects. For large-scale or highly customized orders, a detailed production and delivery schedule will be provided upon order confirmation. Our global logistics network ensures efficient and reliable delivery to your project site. We work with established freight partners to manage international shipping, customs clearance, and local delivery, ensuring your micro inverter solar kit arrives on schedule and in pristine condition.

Warranty Commitments:

TSUN stands behind the quality and reliability of its 2-in-1 Microinverters with an industry-leading warranty. Our standard product warranty covers defects in materials and workmanship for a period of 10 to 25 years, varying by specific product model and region. This comprehensive coverage ensures long-term operational peace of mind. Full details of our warranty policy, including terms, conditions, and claim procedures, are available on our website or can be provided by your sales representative. We are dedicated to prompt and efficient resolution of any warranty claims to minimize system downtime and ensure continuous energy savings from your micro inverter system.

Customer Support:

Our dedicated technical support team is available to assist with any queries related to installation, commissioning, operation, and troubleshooting. Support is accessible via email, telephone, and our online portal during business hours. We also offer comprehensive training programs for our B2B partners, ensuring your technical teams are fully equipped to deploy and maintain our microinverter solutions effectively. Our goal is to build long-term partnerships through exceptional product quality and unwavering customer service.

Conclusion: The Future is Decentralized with AC Micro Inverters

The landscape of solar energy is continually evolving, and the ac micro inverter stands as a testament to this progress. By providing module-level optimization, unparalleled safety, superior reliability, and scalable flexibility, microinverters are redefining performance standards for solar photovoltaic systems. Their ability to deliver consistent energy yield in diverse and challenging environments, coupled with their robust design for corrosion resistance and extended service life, positions them as the intelligent choice for discerning B2B clients.

As the global energy transition accelerates, the demand for efficient, resilient, and intelligent solar solutions will only grow. Investing in advanced solar microinverter systems ensures not only immediate energy savings but also a future-proof energy infrastructure that contributes to a more sustainable and economically viable operation. TSUN, with its commitment to innovation, quality, and comprehensive customer support, is poised to be your trusted partner in harnessing the full potential of solar energy.

References

- International Electrotechnical Commission (IEC) Standards for Photovoltaic Systems.

- Underwriters Laboratories (UL) Standard 1741 for Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources.

- National Renewable Energy Laboratory (NREL) publications on solar PV performance and reliability.

- Solar Energy Industries Association (SEIA) market research and policy briefs.

- Journal of Renewable and Sustainable Energy, various articles on microinverter efficiency and grid integration.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE