Unlocking Solar Potential: The Evolution of PV Micro Inverters

The landscape of solar energy generation has been profoundly transformed by innovations in power electronics, with the pv micro inverter standing at the forefront of this revolution. Unlike traditional string inverters, which convert DC electricity from an entire array of solar panels into AC electricity at a central point, pv micro inverter systems optimize power conversion at the individual module level. This architectural shift significantly enhances energy harvest, improves system resilience, and simplifies scalability, making solar power more accessible and efficient for a wider range of applications, especially in residential and small commercial sectors. The increasing demand for distributed generation, coupled with advancements in semiconductor technology and smart grid integration, is propelling the micro inverter solar market into a period of rapid expansion. This growth is also fueled by stringent safety standards and the desire for modular, flexible solar installations that can adapt to complex rooftop geometries and varying sunlight conditions. As we delve deeper, we will explore how these compact yet powerful devices are not just components but strategic assets, reshaping the global energy paradigm by maximizing yield from every single solar cell, thereby offering unparalleled advantages in system performance and reliability.

Industry trends indicate a decisive pivot towards modularity and intelligence in solar power systems. The proliferation of electric vehicles and the increasing reliance on smart home technologies further underscore the need for efficient, dependable, and easily managed energy sources. In this context, the microinverter emerges as a critical enabler, providing granular control over energy production and facilitating advanced monitoring capabilities. This allows homeowners and businesses to identify performance issues at the panel level, ensuring optimal energy harvest even when individual panels are affected by shading, soiling, or manufacturing variances. The inherent safety benefits, such as the elimination of high-voltage DC lines on rooftops, make microinverter solutions particularly attractive in densely populated areas. Furthermore, the plug-and-play nature of many modern pv microinverter designs simplifies installation and maintenance, reducing labor costs and accelerating deployment times. This comprehensive approach to solar energy conversion not only optimizes immediate energy yield but also contributes to the long-term viability and sustainability of solar installations across diverse climatic and operational environments, ensuring robust performance even in demanding outdoor settings where anti-corrosion properties are crucial.

Technical Deep Dive: Parameters and Performance of PV Micro Inverters

Understanding the core technical specifications of a pv microinverter is crucial for system designers and end-users alike to select the optimal solution for their specific needs. Key parameters often include Maximum Power Point Tracking (MPPT) efficiency, which denotes how effectively the inverter extracts maximum power from the solar panel under varying conditions, typically ranging from 99.5% to 99.8% for leading models. Power output (AC power rating) defines the maximum continuous AC power the inverter can deliver, commonly between 300W and 2000W per unit depending on the number of PV inputs (e.g., 1-in-1, 2-in-1, 4-in-1). The operating voltage range (DC input voltage) specifies the acceptable voltage window from the solar panel, crucial for compatibility. Communication protocols, such as Wi-Fi, Zigbee, or powerline communication (PLC), enable remote monitoring and diagnostics, providing real-time data on energy production and system health. The conversion topology, often utilizing high-frequency switching to achieve compact designs and high efficiency, is a testament to advanced power electronics engineering. Environmental ratings, including IP67 for outdoor dust and water resistance and a wide operating temperature range (e.g., -40°C to +65°C), ensure durability in harsh conditions, making the solar cell micro inverter a robust solution for diverse global climates.

Typical PV Micro Inverter Specifications

| Parameter |

Typical Value Range |

Description |

| MPPT Efficiency |

99.5% - 99.8% |

Maximizes power harvest from individual panels. |

| Peak Output Power (AC) |

300W - 2000W (per unit) |

Rated AC power output, varies by configuration (1-in-1, 2-in-1, etc.). |

| Operating DC Voltage Range |

20V - 60V (or wider) |

Input voltage compatibility with PV modules. |

| Communication |

Wi-Fi, Zigbee, PLC |

Enables remote monitoring and system management. |

| Enclosure Rating |

IP67 |

Protection against dust ingress and water immersion. |

| Operating Temperature |

-40°C to +65°C |

Ensures reliable operation in extreme climates. |

| CEC Weighted Efficiency |

~97.0% - 97.5% |

California Energy Commission metric for real-world performance. |

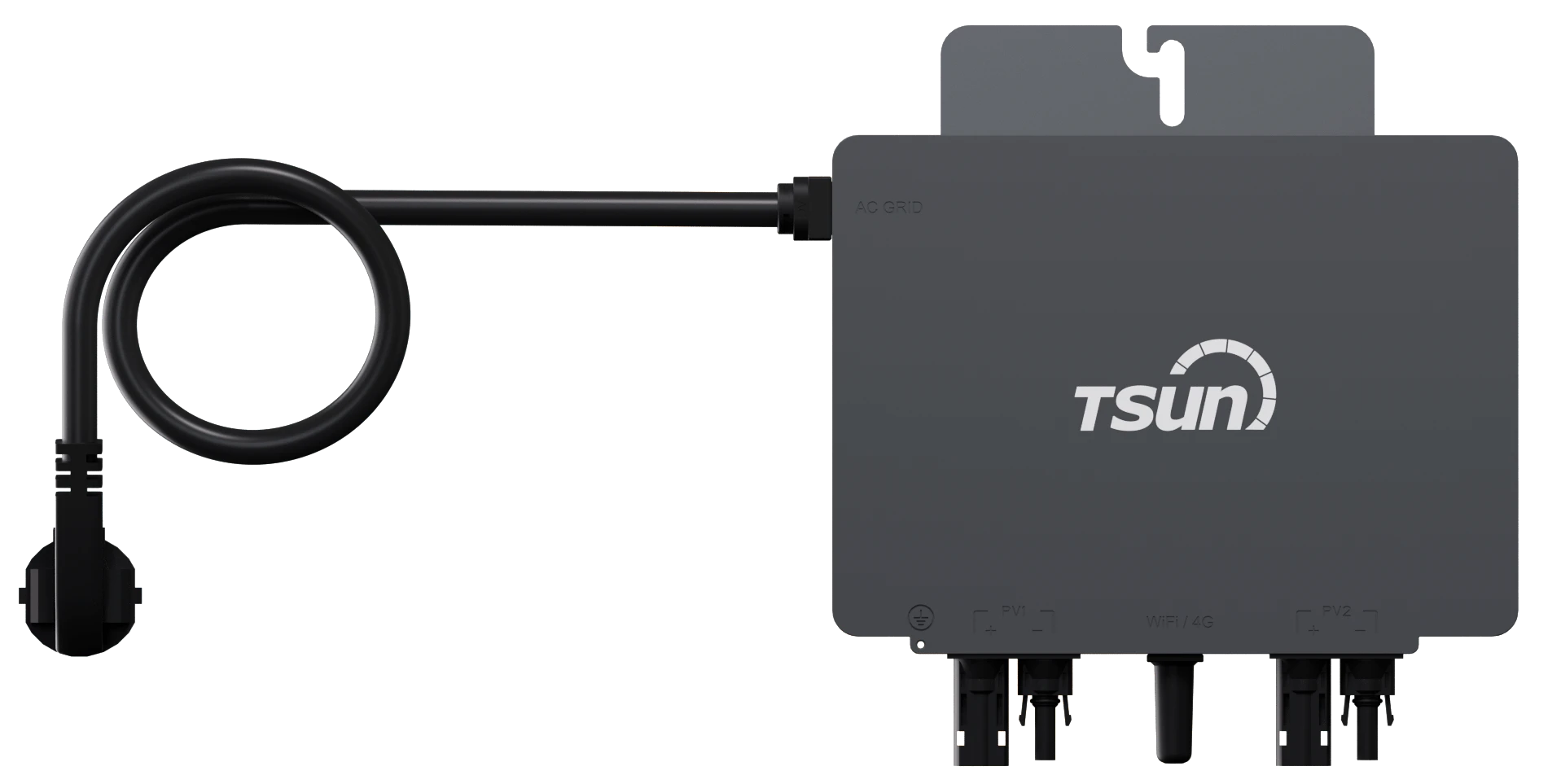

The robust design of modern microinverter units often includes features like integrated ground fault protection, rapid shutdown compliance (NEC 2017/2020), and surge protection, significantly enhancing system safety and grid integration capabilities. Manufacturers like TSUN-ESS leverage advanced digital control algorithms to precisely manage power conversion and grid synchronization, ensuring a stable and high-quality AC output. The compact form factor of the "1-in-1 Balcony microinverter" exemplifies this trend, designed for seamless integration with single PV modules, making it an ideal choice for urban environments or scenarios where space optimization is paramount. The intelligent monitoring platforms that accompany these devices provide comprehensive insights into energy production, consumption, and even carbon offset, empowering users with data-driven decision-making. Such sophisticated integration of hardware and software underlines the maturity and efficacy of pv micro inverter technology as a foundational element for future distributed energy systems.

Manufacturing Excellence and Quality Assurance in PV Micro Inverter Production

The production of a high-performance pv micro inverter involves a sophisticated multi-stage manufacturing process, meticulously designed to ensure reliability, durability, and peak operational efficiency. It commences with the careful selection of premium-grade components: advanced semiconductors for power conversion (e.g., SiC/GaN-based MOSFETs), robust capacitors for energy storage, and high-quality magnetics for transformer stages. The outer casing is typically crafted from durable aluminum alloy, often treated with anti-corrosive coatings and designed for optimal heat dissipation, ensuring longevity in outdoor environments. The manufacturing flow generally includes automated PCB assembly utilizing pick-and-place machines for precise component placement, followed by wave soldering or reflow soldering for secure connections. Critical stages involve rigorous testing: burn-in tests to stress components and identify early failures, functional tests to verify electrical parameters, and environmental chamber tests to simulate extreme temperatures and humidity, ensuring performance stability from -40°C to +65°C.

Quality control is paramount and integrated throughout the entire production lifecycle, not just at the final stage. This includes comprehensive Incoming Quality Control (IQC) for raw materials, In-Process Quality Control (IPQC) at each assembly stage, and Final Quality Control (FQC) before packaging and shipment. Manufacturers adhere to stringent international standards such as UL 1741 for safety, IEC 62109 for power conversion equipment, and CE marking for European market compliance, alongside ISO 9001 for quality management systems and ISO 14001 for environmental management. For specialized applications, compliance with specific grid codes and regulations (e.g., IEEE 1547 for interconnection, VDE-AR-N 4105 for Germany) is also crucial. The expected operational lifespan of a high-quality pv micro inverter is typically 20-25 years, mirroring that of solar panels, which is a testament to the robust design and rigorous testing protocols employed. This longevity is critical for return on investment in residential, commercial, and utility-scale solar installations. These microinverters excel in environments requiring high reliability and minimum maintenance, such as critical infrastructure, balcony systems, or remote monitoring stations where their anti-corrosion properties and stable output are highly valued.

Application Scenarios and Strategic Advantages of Micro Inverter Solar Systems

The inherent design and operational characteristics of micro inverter solar systems make them exceptionally versatile for a myriad of applications, extending far beyond the conventional rooftop installation. For residential deployments, the module-level optimization is a significant advantage, particularly in scenarios where roofs are subject to partial shading from trees, chimneys, or adjacent buildings. Each microinverter ensures that even if one panel's output is compromised, the performance of other panels remains unaffected, maximizing overall system yield. This contrasts sharply with string inverters, where the weakest panel can drag down the performance of the entire string. Furthermore, the inherent safety of pv microinverter systems is unparalleled; by converting DC to AC at the panel, high-voltage DC lines, which pose fire risks, are eliminated from the rooftop, significantly reducing hazards for installers and homeowners alike. The scalability of these systems is another key benefit: users can incrementally add panels and corresponding microinverters as their energy needs evolve or as budget allows, without redesigning the entire system architecture.

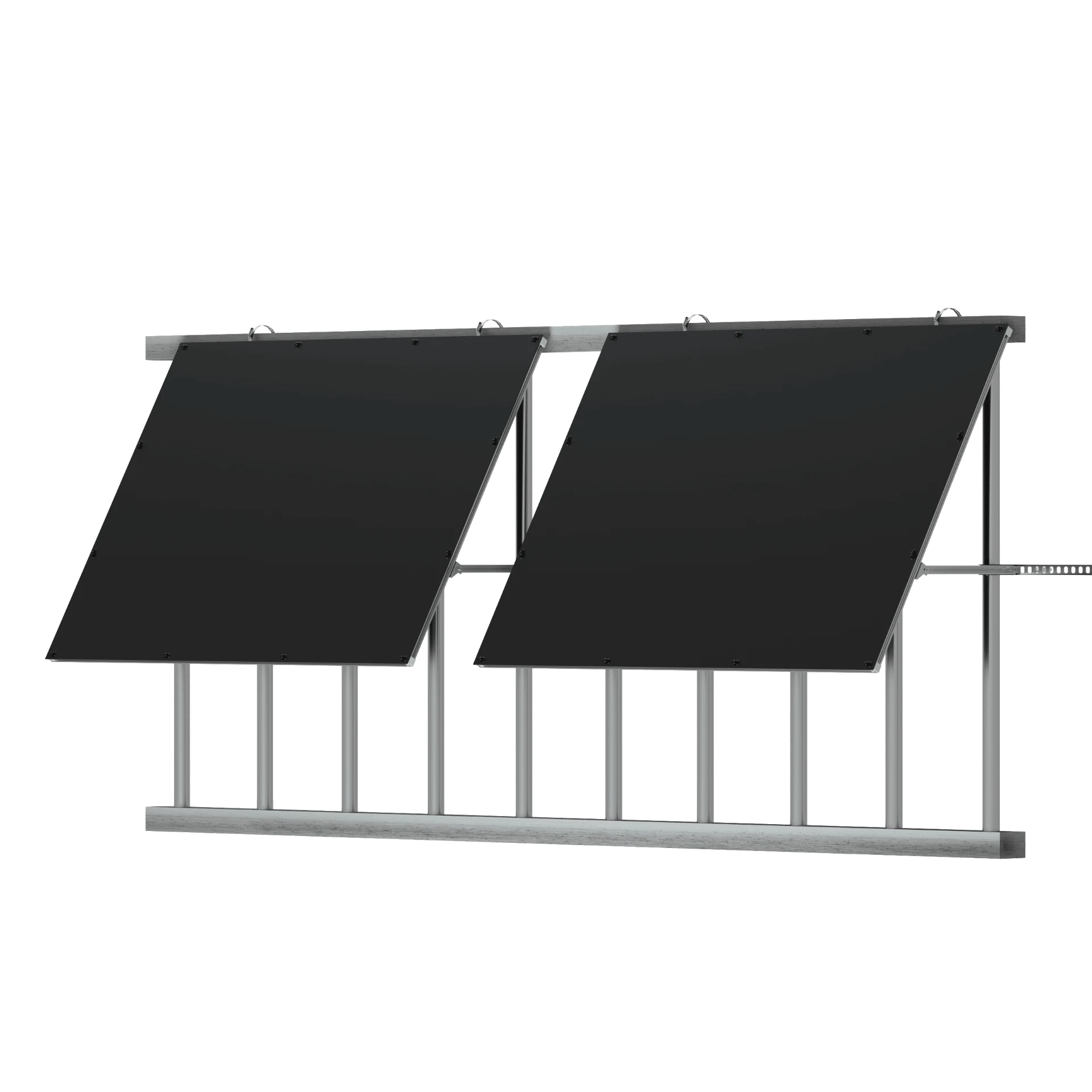

Beyond traditional residential rooftops, the "1-in-1 Balcony microinverter" exemplifies the expanded utility of these devices, specifically targeting urban dwellers or those with limited roof space. These compact units facilitate plug-and-play solar solutions for balconies, patios, or small garden sheds, making solar energy accessible to a broader demographic. For commercial applications, especially those with complex rooflines or varied orientations, pv microinverter solutions provide unparalleled design flexibility and resilience. Distributed MPPT ensures that each panel contributes its maximum, even if some panels are oriented differently or experience varying sun exposure throughout the day. The comprehensive monitoring capabilities, often accessible via web portals or mobile apps, allow for real-time performance tracking and fault detection at the individual solar cell micro inverter level, simplifying maintenance and ensuring continuous peak performance. This granular control and robust performance underscore why micro inverter solar technology is increasingly becoming the preferred choice for forward-thinking solar installations, promising both superior energy production and enhanced operational safety.

Manufacturer Comparison and Tailored PV Micro Inverter Solutions

In the competitive landscape of solar energy, selecting the right pv micro inverter manufacturer involves more than just comparing spec sheets; it requires a holistic evaluation of product quality, technological innovation, warranty coverage, and customer support. Leading manufacturers differentiate themselves through superior MPPT algorithms, higher conversion efficiencies (often exceeding 97.5% CEC weighted efficiency), and advanced communication platforms that provide granular system data. For instance, some manufacturers specialize in multi-input microinverters (e.g., 2-in-1 or 4-in-1 units for higher power systems), while others, like TSUN-ESS with its "1-in-1 Balcony microinverter," focus on highly modular, single-panel solutions ideal for specific niche markets or smaller-scale deployments. Critical factors to consider include the robustness of the monitoring portal, the responsiveness of technical support, and the longevity of the product warranty, which typically ranges from 10 to 25 years, reflecting confidence in the product's lifespan.

Beyond standard offerings, the capacity for delivering customized solutions marks a truly authoritative provider. For B2B clients, this might involve tailoring communication protocols for specific smart grid integrations, designing specialized enclosures for extreme environmental conditions, or developing unique power output configurations to match particular commercial requirements. A reputable microinverter supplier will engage in thorough consultation to understand the client's unique challenges, whether it's optimizing energy yield for a shaded industrial roof or providing a scalable solution for a phased commercial development. This commitment to bespoke engineering ensures that the chosen pv microinverter system is not just off-the-shelf but precisely aligned with operational goals, maximizing return on investment and ensuring long-term system performance. The "1-in-1 Balcony microinverter" from TSUN-ESS, for example, is a testament to this, designed specifically to address the growing demand for accessible, compact, and highly efficient solar solutions in urban settings, demonstrating a keen understanding of evolving market needs and a proactive approach to product development.

Real-World Impact: Application Cases and Customer Success with PV Micro Inverters

The tangible benefits of pv micro inverter technology are best illustrated through real-world application cases and invaluable customer feedback. Consider a residential project in an urban area with a complex roofline and intermittent shading throughout the day. By deploying a micro inverter solar system, the homeowner observed a significant increase in daily energy harvest compared to simulations with a string inverter, specifically attributing the gains to the module-level MPPT. Monitoring data clearly showed that shaded panels continued to produce power optimally, without affecting adjacent unshaded modules. Another compelling case involved a small commercial building seeking to incrementally expand its solar capacity without disrupting ongoing operations. The inherent modularity of the microinverter system allowed for phased installation, adding new panels and microinverters as budget became available, minimizing upfront costs and maximizing flexibility. Customer testimonials consistently highlight the ease of installation, the robust reliability, and the peace of mind derived from advanced safety features and comprehensive monitoring.

Service cases further underscore the reliability and support associated with high-quality pv microinverter deployments. In a rare instance of a module-level fault, the precise diagnostic capabilities of the monitoring platform allowed for immediate identification of the affected unit, enabling a targeted repair or replacement without impacting the rest of the array. This dramatically reduces maintenance time and costs, ensuring minimal downtime for energy production. Feedback from installers frequently praises the simplified wiring, the elimination of high-voltage DC risks, and the straightforward commissioning process, which contributes to faster project completion times. For solutions like the "1-in-1 Balcony microinverter," customer satisfaction stems from its accessibility and ease of use for DIY enthusiasts or those with modest energy needs, making solar power attainable for diverse living situations. These experiences solidify the position of pv micro inverter technology as a superior choice for performance, safety, and long-term value in the evolving solar energy market, proving its efficacy through demonstrable success stories across various sectors.

Ensuring Trust and Authority: Certifications, Warranties, and Customer Support

For B2B stakeholders, trust and authority are paramount when investing in solar technology. Reputable pv micro inverter manufacturers substantiate their claims through a robust portfolio of international certifications, demonstrating adherence to the highest standards of safety, quality, and performance. Key certifications include UL 1741 (Standard for Inverters, Converters, Controllers and Interconnection System Equipment for Use with Distributed Energy Resources), vital for North American markets; IEC 62109 (Safety of power converters for use in photovoltaic power systems), crucial globally; and CE marking, mandatory for products sold within the European Economic Area. TÜV Rheinland and VDE certifications further validate product safety and performance, often specific to certain regional grid codes. Beyond product-specific certifications, adherence to ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) signals a manufacturer's commitment to consistent quality and responsible operations. These credentials provide objective assurance that the microinverter meets rigorous industry benchmarks, fostering confidence in its reliability and longevity.

The commitment to customer satisfaction extends through comprehensive warranty programs and responsive technical support. Leading pv micro inverter warranties typically span 10 to 25 years, mirroring the expected lifespan of solar panels, underscoring the product's durability and the manufacturer's confidence. This long-term assurance protects investment and provides peace of mind. Delivery cycles are optimized through efficient supply chain management and global logistics networks, ensuring timely project completion for large-scale deployments or individual orders. Furthermore, dedicated customer support channels, including technical hotlines, online ticketing systems, and detailed knowledge bases, are critical for prompt issue resolution and ongoing system optimization. Many providers also offer robust monitoring platforms with API access, enabling seamless integration with broader energy management systems. For the "1-in-1 Balcony microinverter" and similar products, accessible customer support, clear installation guides, and a commitment to post-sales service reinforce the trustworthiness of the brand, ensuring that every solar investment is backed by reliable technology and unwavering support.

Frequently Asked Questions (FAQs)

-

Q: What is the primary advantage of a pv micro inverter over a string inverter?

A: The main advantage is module-level power optimization, meaning each solar panel operates independently at its maximum power point. This prevents shading or performance issues on one panel from affecting the output of others, leading to higher overall energy harvest, enhanced safety, and greater system flexibility and scalability.

-

Q: How do microinverter systems enhance safety?

A: By converting DC power to AC power directly at the solar panel, microinverters eliminate high-voltage DC wiring runs across the rooftop. This significantly reduces the risk of electrical fires and makes installations safer for both installers and building occupants. They often comply with rapid shutdown requirements.

-

Q: What is the typical lifespan of a pv microinverter?

A: High-quality PV microinverters are designed for longevity, with an expected operational lifespan of 20-25 years, aligning with the lifespan of most solar panels. This is supported by robust manufacturing processes, rigorous testing, and comprehensive warranties.

-

Q: Can I monitor the performance of individual solar panels with a microinverter system?

A: Yes, one of the key features of microinverter systems is their ability to provide module-level monitoring. Through a dedicated web portal or mobile application, users can track the energy production of each individual solar panel in real-time, allowing for precise performance analysis and rapid fault detection.

Conclusion: The Future of Distributed Solar with PV Micro Inverters

The emergence and continuous evolution of the pv micro inverter have fundamentally reshaped the paradigm of solar energy generation, moving it from centralized, rigid systems to decentralized, flexible, and intelligent power sources. This technology's ability to maximize energy harvest at the individual module level, coupled with unparalleled safety features and superior system resilience, positions it as a cornerstone of modern distributed renewable energy infrastructure. As global energy demands intensify and the imperative for sustainable solutions grows, the adoption of micro inverter solar systems will only accelerate. From enhancing efficiency in shaded urban environments with products like the "1-in-1 Balcony microinverter" to enabling scalable, robust installations for commercial entities, the advantages are clear and compelling. The ongoing innovation in power electronics, materials science, and communication protocols ensures that future generations of pv microinverter systems will continue to deliver even higher efficiencies, greater grid interactivity, and more sophisticated monitoring capabilities, further solidifying their role in a smart, decentralized energy future.

The focus on precision engineering, stringent quality assurance, and comprehensive customer support, backed by authoritative certifications and robust warranties, collectively builds a foundation of trust essential for B2B engagement. As the world transitions towards a more sustainable and electrified future, the strategic importance of reliable, high-performance energy conversion devices cannot be overstated. The pv microinverter, therefore, is not merely a component in a solar array; it is a vital enabler of energy independence, a driver of efficiency, and a key contributor to building a resilient, greener grid. Its capacity to transform sunlight into usable power with minimal loss and maximum safety makes it an indispensable technology for anyone looking to harness the full potential of solar energy today and for decades to come.

Authoritative References

- National Renewable Energy Laboratory (NREL). Solar Photovoltaic (PV) Technologies.

- International Energy Agency (IEA). Trends in Photovoltaic Applications.

- Institute of Electrical and Electronics Engineers (IEEE). Standards for Interconnecting Distributed Resources.

- Underwriters Laboratories (UL). Standard for Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources (UL 1741).

- California Energy Commission (CEC). Efficiency Standards for Solar Inverters.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE