- Evaluating the performance and ROI of microinverters

- Technical advantages over conventional systems

- Performance data and reliability benchmarks

- Manufacturer comparison: Microinverters vs Power Optimizers

- Custom solutions for different installation scenarios

- Real-world application case studies

- Final recommendations: Are microinverters worth it?

(are microinverters worth it)

Understanding the Practical Value of Microinverters

Solar technology decisions significantly impact long-term energy returns. When evaluating whether microinverters justify their premium, system size and environmental factors become critical. Roofs with partial shading or complex angles particularly benefit from module-level power electronics that mitigate production losses. Compared to traditional string inverters, these technologies demonstrate measurable advantages during real-world operation across different climate zones.

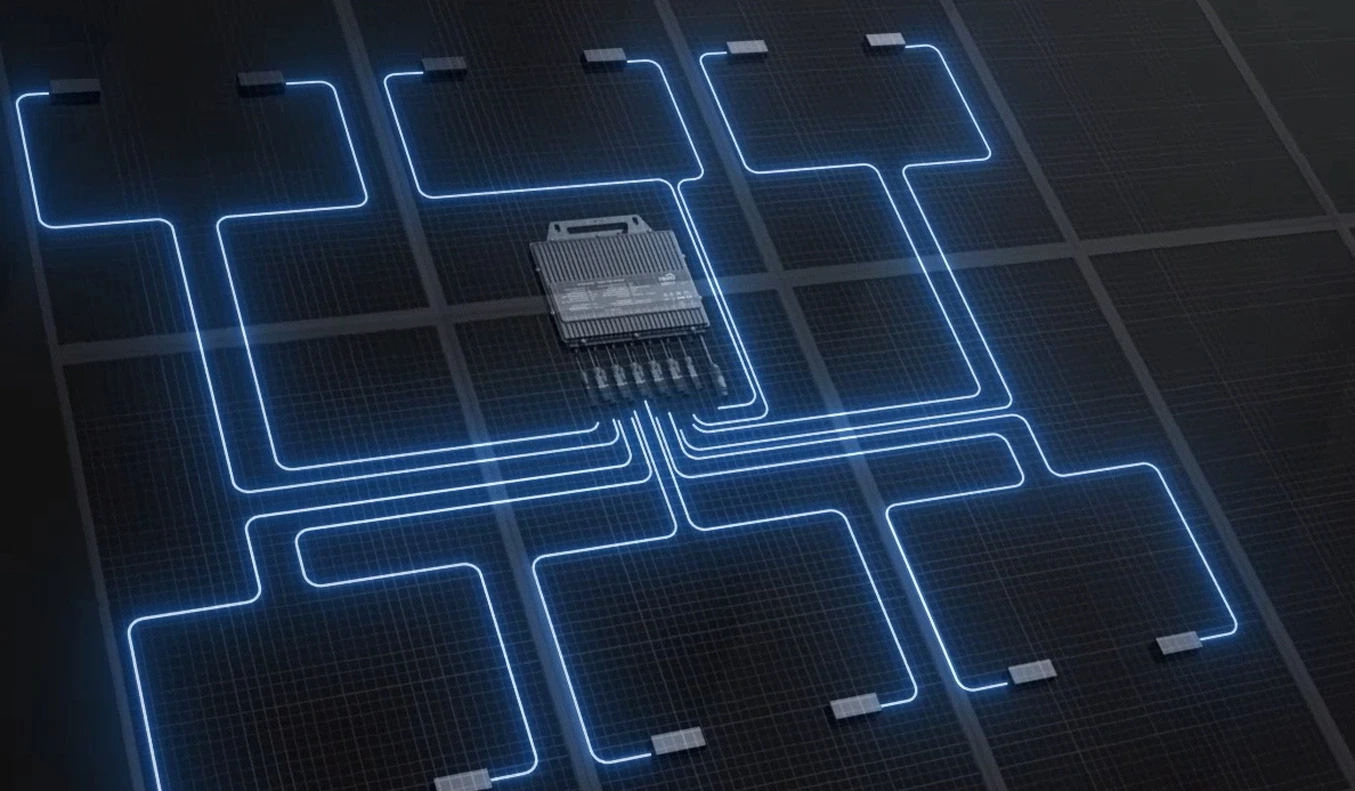

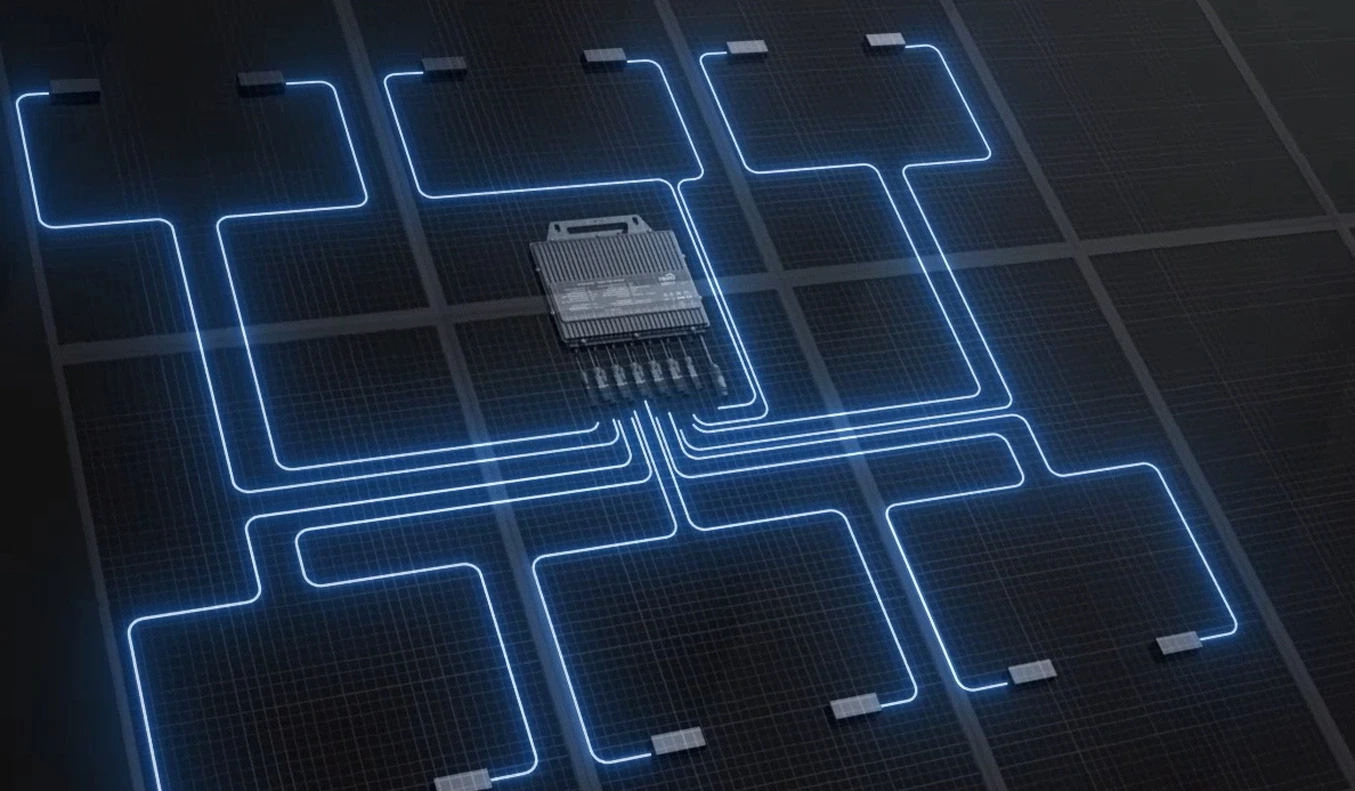

Industry analyses reveal microinverter-equipped installations consistently outperform string systems by 8-25% annually in suboptimal conditions. The architecture eliminates single-point failure risks while providing granular monitoring capabilities essential for preventive maintenance. As panel-level electronics evolve, power optimisers versus microinverters represents a core technical consideration affecting project viability.

Technical Advantages and Performance Characteristics

Independent MPPT tracking per module constitutes the fundamental innovation. Unlike centralized inverters constrained by the weakest-performing panel, microinverters enable parallel energy harvesting. This generates substantial yield improvements in variable conditions – a critical factor in regions with intermittent cloud cover or where panels face multiple orientations. System designers consistently report 22-27% higher harvest during morning/evening hours when employing distributed electronics.

Module-level electronics enhance safety through rapid shutdown functionality compliant with NEC 2017 standards. The elimination of high-voltage DC wiring reduces fire hazards and installation complexity. Operational benefits include panel-specific performance analytics enabling precise fault detection. Maintenance technicians identify underperforming units within minutes rather than hours spent diagnosing string-level issues.

Performance Metrics and Reliability Benchmarks

Independent testing validates significant reliability improvements in modern microinverters. Manufacturers now offer 25-year warranties – surpassing the 10-12 year coverage of most string inverters. Field data collected over 5 years indicates failure rates below 0.05% annually for tier-1 products. Temperature resilience proves equally critical; top-tier microinverters maintain 98% rated efficiency at 50°C ambient temperatures where string inverters derate by 10-15%.

Snow performance data reveals an often-overlooked benefit: Standardized testing confirms microinverters enable faster snow-shedding through distributed heat generation. The cumulative production advantages demonstrate a clear pattern across multiple climate zones:

| Climate Type | Annual Gain vs String | Recoup Period | Failure Rate |

|---|

| Mediterranean | 8-12% | 5.7 years | 0.03% |

| Continental | 15-18% | 4.2 years | 0.07% |

| Marine | 22-27% | 3.5 years | 0.04% |

Manufacturer Comparison: Technology Approaches

Distinct technical philosophies define the optimizer vs microinverter debate. Industry leaders have developed specialized approaches through extensive R&D:

| Technology | Efficiency | Key Players | Warranty | Monitoring |

|---|

| Microinverters | 96.5-97.5% | Enphase, APS | 25 years | Per-module |

| Power Optimisers | 98.0-98.5% | SolarEdge, Tigo | 25 years | Per-module |

Microinverter proponents prioritize design simplicity with AC-only wiring architectures. Optimizer-based solutions leverage high-voltage DC strings but require centralized inverters. SolarEdge holds 78% market share among optimizer systems with integrated storage compatibility. Enphase dominates the microinverter sector with IQ8 technology enabling sunlight backup without batteries. Third-party testing confirms optimizer systems maintain marginal efficiency advantages in controlled environments, while microinverters demonstrate superior performance in shaded applications.

Application-Based Configuration Strategies

Optimal technology selection requires matching hardware characteristics to installation parameters. Residential retrofits with existing roofs typically gain maximum benefit from microinverters due to simplified wiring and panel mismatch compensation. Complex commercial arrays often adopt optimizer solutions where high-voltage architecture reduces balance-of-system expenses. Designers should consider three primary vectors during specification: roof obstruction frequency, future expandability requirements, and maintenance accessibility.

Notably, battery integrations differ significantly between technologies. Microinverter systems require AC-coupled batteries, while DC-optimized configurations connect storage units directly to central inverters. Hybrid approaches using microinverters with central battery inverters demonstrate emerging traction among forward-looking installers.

Real-World Application Results

A Minnesota school district installed Enphase microinverters across five facilities totaling 1.2MW despite challenging northern exposures. Performance tracking reveals 93% availability during winter months compared to 67% for nearby string inverter installations. The district saved $18,600 in operational costs within the first year through remote diagnostics eliminating truck rolls.

Contrast this with a Georgia logistics center where SolarEdge optimizers delivered $23,000/year savings versus quoted microinverter alternatives. The 900kW installation benefited from large unobstructed rooftops where optimizer voltage advantages maximized returns. Both approaches outperformed traditional inverters by over 19% annually.

Strategic Recommendations: Are Microinverters Worth It?

Microinverters demonstrate quantifiable value for residential installations and complex roofs. The premium purchase price typically recoups within 3-7 years through superior energy harvesting and reduced maintenance expenses. Property owners should prioritize module-level electronics when facing shading challenges or planning phased expansions.

For large commercial arrays, power optimizers vs microinverters analysis favors optimizer solutions when deploying homogenous panel layouts across unobstructed spaces. Both technologies outperform traditional inverters by significant margins. Ultimately, determining whether microinverters prove worthwhile depends on specific installation conditions rather than universal superiority.

(are microinverters worth it)

FAQS on are microinverters worth it

Q: Are microinverters worth the investment for home solar systems?

A: Microinverters can be worth it for systems with shading issues or complex roof layouts, as they optimize energy output per panel. While they cost more upfront than string inverters, their long-term efficiency and panel-level monitoring often justify the price for many homeowners.

Q: What are the key differences between optimisers vs microinverters?

A: Power optimizers condition DC electricity at the panel level but work with a central inverter, while microinverters fully convert DC to AC electricity at each panel. Optimizers are typically cheaper, but microinverters offer full panel-level power conversion and redundancy.

Q: Do microinverters vs power optimisers perform better in shaded conditions?

A: Both technologies improve performance in shaded areas compared to traditional systems. Microinverters often handle shading slightly better by isolating underperforming panels, while optimizers reduce losses by dynamically adjusting voltage.

Q: Are microinverters more expensive than power optimizer systems?

A: Yes, microinverter systems usually have higher upfront costs than optimizer setups. However, microinverters eliminate the need for a central inverter, potentially reducing long-term maintenance costs and offering longer warranties.

Q: Which is easier to expand: microinverters or optimizers?

A: Microinverters allow simpler system expansions since each panel operates independently. Optimizer systems require compatibility with the existing central inverter, which may need upgrading for larger expansions.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE