The Strategic Role of Advanced Battery Packs in Modern Industries

In the rapidly evolving landscape of energy storage and power solutions, the Battery Pack stands as a cornerstone technology. Essential for everything from grid-scale energy storage to electric vehicles and mission-critical industrial applications, these integrated power units are designed for optimal performance, safety, and longevity. Modern industrial trends underscore a significant shift towards higher energy density, increased cycle life, enhanced safety protocols, and greater modularity in power solutions. As global energy demands grow and sustainability targets become more stringent, the impetus to develop and deploy highly efficient and reliable battery packs intensifies across diverse sectors, driving innovation in materials science, manufacturing processes, and intelligent management systems.

The current market is characterized by a strong push for lithium-ion based solutions, predominantly Lithium Iron Phosphate (LiFePO4 or LFP) and Nickel Manganese Cobalt (NMC), due to their superior energy-to-weight ratios, extended cycle lives, and declining costs. This has fueled their adoption in renewable energy integration, where they provide crucial grid stabilization and demand response capabilities, and in industrial electrification, where they replace traditional fossil fuel generators with cleaner, more efficient alternatives. Future trends point towards solid-state batteries, advanced thermal management systems, and sophisticated AI-driven Battery Management Systems (BMS) that promise even greater performance benchmarks and safety assurances.

Manufacturing Process Flow: Engineering Excellence

The production of a high-quality Battery Pack involves a rigorous, multi-stage manufacturing process designed to ensure peak performance, reliability, and safety. Each stage is meticulously controlled, adhering to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

- Material Sourcing & Cell Selection: The foundation of any robust battery pack begins with the selection of premium battery cells, typically LiFePO4 or NMC, sourced from tier-1 manufacturers. These cells undergo stringent initial testing for capacity, internal resistance, and voltage consistency to ensure homogeneity within the pack. Key components like the Battery Management System (BMS), high-conductivity busbars (often copper or aluminum), thermal management materials, and durable housing materials are also sourced, meeting specific metallurgical and electrical criteria.

- Cell Assembly & Module Fabrication: Selected cells are then assembled into modules. This process involves automated precision welding (e.g., laser welding, ultrasonic welding) of busbars to cell terminals, ensuring minimal resistance and uniform current distribution. Each module is then subjected to dielectric strength tests and thermal cycling to assess structural integrity and performance under varying conditions.

- BMS Integration & Wiring Harness: The sophisticated BMS, often featuring advanced algorithms for state-of-charge (SOC), state-of-health (SOH) estimation, and cell balancing, is integrated. This involves precise wiring harness assembly and connection to individual cells and temperature sensors. All connections are validated for continuity and insulation resistance.

- Housing Fabrication & Environmental Protection: The modules and BMS are enclosed within a custom-designed housing, often constructed from robust metals (e.g., aluminum, stainless steel) or high-strength plastics. Manufacturing processes for housing include CNC machining, stamping, and welding, ensuring precise fitment and structural integrity. Special attention is given to achieving specific ingress protection (IP) ratings (e.g., IP65, IP67) for dust and water resistance, crucial for industrial deployment. Corrosion resistance is often enhanced through specialized coatings or material selection, vital for target industries like petrochemicals and water treatment.

- Final Assembly & Quality Control: The complete system undergoes final assembly, including installation of cooling systems, communication interfaces (CAN bus, RS485), and safety mechanisms (fuses, contactors). Comprehensive quality control checks are performed, encompassing visual inspection, electrical performance validation, and functional testing of the BMS. This stage often includes burn-in tests, where the pack is cycled under simulated operational loads.

- Testing & Certification: Each finished Battery Pack is subjected to rigorous end-of-line testing. This includes capacity tests, discharge performance under various loads, charge efficiency, thermal runaway prevention tests, and vibration/shock resistance. Products are certified to relevant international standards such as IEC 62619 (safety for secondary lithium cells and batteries for industrial applications), UL 1973 (batteries for use in stationary and motive auxiliary power applications), UN 38.3 (transport safety), and ANSI standards where applicable, ensuring broad market acceptance and safe deployment. Our products are designed for an exceptional service life, typically exceeding 6,000 to 8,000 cycles at 80% Depth of Discharge (DoD).

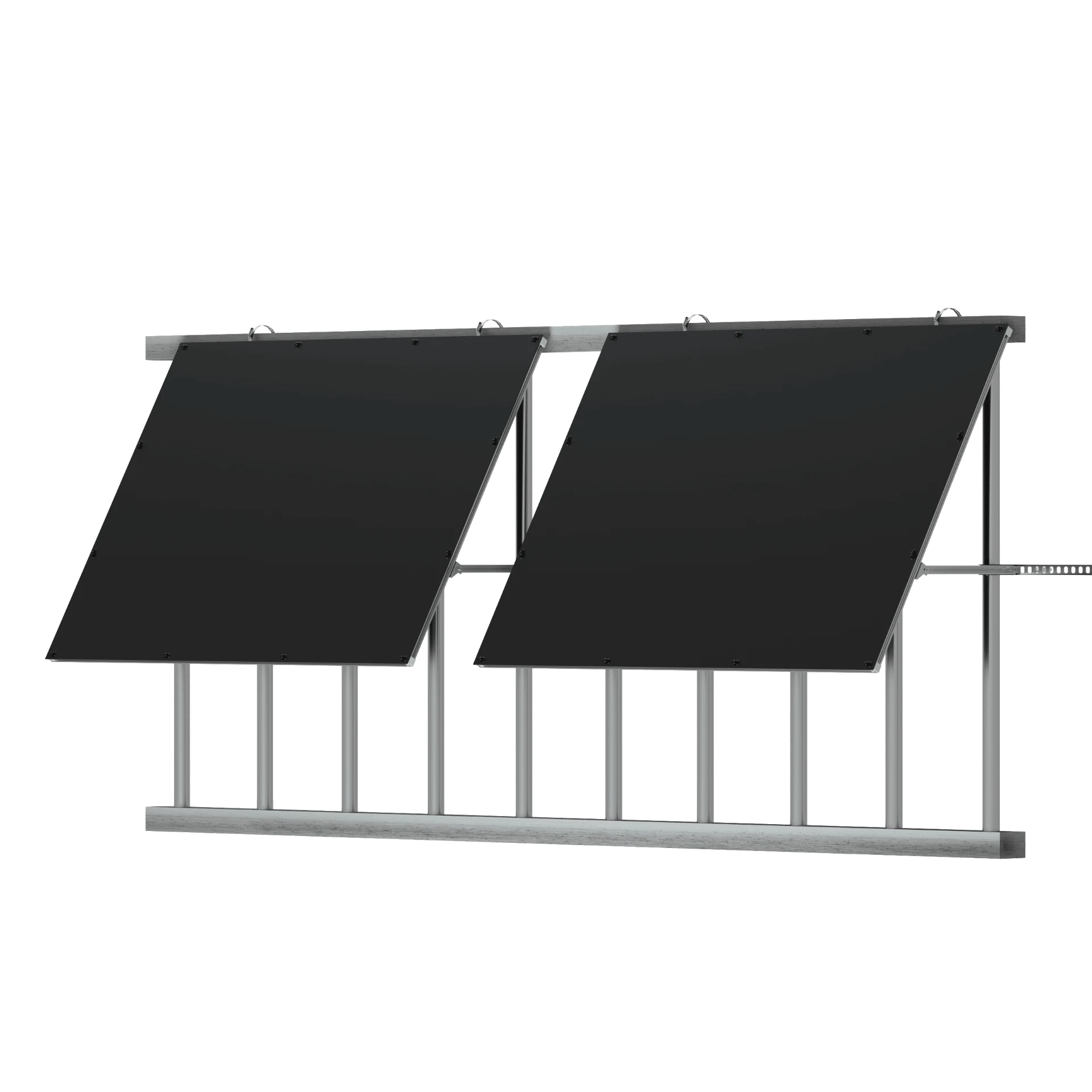

Image: Advanced modular Battery Pack system ready for industrial deployment.

Technical Specifications: Precision Engineered for Performance

Our advanced Battery Pack solutions are engineered to meet the demanding requirements of industrial applications, combining high energy density with exceptional longevity and robust safety features. The following table provides typical specifications for a high-performance industrial battery pack:

Typical Industrial Battery Pack Specifications

| Parameter |

Value/Description |

| Cell Chemistry |

Lithium Iron Phosphate (LiFePO4/LFP) |

| Nominal Voltage |

48V / 51.2V (Customizable from 12V to 1000V+) |

| Nominal Capacity |

100Ah - 5000Ah+ (Scalable) |

| Usable Energy |

5 kWh - 2 MWh+ (Scalable) |

| Cycle Life (80% DoD) |

≥6,000 cycles @ 25°C |

| Max Continuous Charge/Discharge Current |

0.5C / 1C (Customizable) |

| Operating Temperature Range |

-20°C to +60°C (Discharge); 0°C to +45°C (Charge) |

| Communication Interfaces |

CAN, RS485, RS232, Ethernet |

| Ingress Protection (IP) Rating |

IP54 / IP65 / IP67 (Dependent on housing) |

| BMS Features |

Over-charge/discharge protection, over-current, over-temp, cell balancing, short-circuit, pre-charge, fault diagnostics |

| Certifications |

CE, RoHS, UN 38.3, IEC 62619, UL 1973 (model specific) |

| Warranty |

Typically 5-10 years or specified cycle count |

Our engineering team leverages extensive experience to optimize these parameters for specific application profiles, ensuring that each Battery Pack delivers unparalleled performance and reliability.

Technical Advantages: Unlocking Operational Excellence

- Exceptional Longevity and Cycle Life: Utilizing premium LiFePO4 cells, our battery packs offer a significantly longer cycle life (typically 6,000 to 8,000 cycles at 80% DoD) compared to lead-acid or even other lithium chemistries. This translates into lower total cost of ownership (TCO) and reduced maintenance, a critical advantage for continuous industrial operations.

- High Energy Density and Space Efficiency: Our designs prioritize compact footprints, delivering substantial power and energy in a smaller volume. This is crucial for applications where space is at a premium, such as telecommunication shelters, industrial machinery, or marine systems, leading to easier integration and installation.

- Enhanced Safety Features with Advanced BMS: Every Battery Pack integrates a sophisticated Battery Management System (BMS) that actively monitors cell voltage, temperature, and current. This system provides multiple layers of protection against over-charge, over-discharge, over-current, short-circuit, and thermal runaway, ensuring safe and reliable operation even under challenging conditions.

- Rapid Charging and High Discharge Capabilities: Designed for efficiency, our battery packs support faster charging rates, minimizing downtime and maximizing operational uptime. They also maintain stable voltage output even during high discharge rates, which is vital for demanding industrial loads, contributing to significant energy saving by reducing energy loss during charge/discharge cycles.

- Robustness and Environmental Resilience: Built to withstand harsh industrial environments, our battery packs feature ruggedized enclosures with high IP ratings (e.g., IP65, IP67) for superior resistance to dust, water, and vibration. Specialized coatings and material choices enhance corrosion resistance, extending service life in corrosive atmospheres prevalent in petrochemical or water treatment plants.

- Modular and Scalable Design: Our modular approach allows for easy scaling of capacity and voltage to meet specific project requirements. This flexibility simplifies integration into existing systems and provides future-proofing for expanding energy needs.

Application Scenarios & Target Industries

The versatility and robust performance of our Battery Pack solutions make them ideal for a wide array of demanding industrial applications across critical sectors:

- Petrochemical Industry: Providing reliable backup power for critical control systems, emergency lighting, and instrumentation in refineries and chemical processing plants, where uninterrupted operation is paramount for safety and productivity. The enhanced corrosion resistance of our enclosures ensures long-term reliability in aggressive chemical environments.

- Metallurgy: Powering heavy machinery, conveying systems, and specialized equipment in foundries and steel mills. Our battery packs offer robust power delivery under extreme temperature fluctuations and high vibration, contributing to significant energy saving by optimizing peak load management.

- Water Supply & Drainage Systems: Ensuring continuous operation of pumps, valves, and monitoring equipment in municipal water treatment facilities, pumping stations, and wastewater management. Reliability is critical to prevent environmental hazards and maintain public services. The sealed, corrosion-resistant designs are perfectly suited for humid and corrosive underground environments.

- Renewable Energy Storage: Integrated with solar photovoltaic and wind turbine systems for grid stabilization, peak shaving, and providing reliable off-grid power solutions for remote industrial sites. This includes large-scale utility storage and smaller microgrid applications.

- Uninterruptible Power Supplies (UPS) for Data Centers & Telecom: Delivering immediate and stable power during outages for critical IT infrastructure, ensuring data integrity and communication continuity.

- Electric Material Handling Equipment: Powering forklifts, automated guided vehicles (AGVs), and other industrial vehicles, offering longer runtimes, faster charging, and zero emissions compared to traditional lead-acid batteries.

- Marine & Offshore Applications: Providing propulsion or auxiliary power for vessels, ensuring compliance with environmental regulations and enhancing operational efficiency in harsh marine conditions.

Vendor Comparison: Why Choose Our Battery Packs

When evaluating battery pack suppliers, it's crucial to consider not just initial cost but also long-term performance, reliability, safety, and support. Our solutions are designed to outperform competitors on several key metrics, ensuring superior value and peace of mind for B2B clients.

Battery Pack Vendor Comparison

| Feature |

TSUN ESS Battery Pack |

Generic Competitor A (Budget) |

Generic Competitor B (Premium) |

| Cell Chemistry |

LiFePO4 (Grade A) |

LiFePO4 (Mixed Grades) |

LiFePO4/NMC (Grade A) |

| Cycle Life (80% DoD) |

≥6,000 cycles |

3,000 - 4,000 cycles |

5,000 - 7,000 cycles |

| BMS Sophistication |

Advanced, intelligent, remote monitoring |

Basic protection |

Advanced, some remote features |

| Thermal Management |

Active (fans/liquid cooling), robust sensors |

Passive (ventilation) |

Hybrid (passive + limited active) |

| Environmental Rating |

IP54/IP65/IP67 options, corrosion resistant |

IP20-IP40 (indoor use) |

IP54/IP55 |

| Customization Options |

Extensive (voltage, capacity, form factor, comms) |

Limited (standard models) |

Moderate |

| Certifications |

CE, RoHS, UN 38.3, IEC 62619, UL 1973 |

Basic CE/RoHS |

Select international standards |

| Warranty |

5-10 Years |

1-3 Years |

5-7 Years |

Our commitment to engineering excellence and adherence to the highest industry standards ensure that our Battery Pack solutions provide superior performance, longevity, and overall value, minimizing operational risks and maximizing ROI for our industrial clients.

Customized Solutions: Tailored to Your Specific Demands

Recognizing that no two industrial applications are exactly alike, we specialize in providing highly customized Battery Pack solutions. Our engineering team works collaboratively with clients to understand precise operational parameters, environmental conditions, and integration challenges. This bespoke approach ensures that the final product perfectly aligns with project requirements, maximizing efficiency and minimizing unforeseen complications.

Customization options include:

- Voltage and Capacity Scaling: From low-voltage systems to high-voltage grid-scale solutions, we design packs to deliver the exact power and energy storage required.

- Form Factor and Mechanical Integration: Tailoring physical dimensions, weight distribution, and mounting configurations to fit existing enclosures or specific space constraints.

- Communication Protocols: Integrating specific communication interfaces (e.g., Modbus, Ethernet/IP, CANOpen) for seamless interaction with existing supervisory control and data acquisition (SCADA) systems or industrial automation platforms.

- Environmental Hardening: Designing for extreme temperatures, high humidity, vibration, corrosive atmospheres, or explosive environments, with tailored IP ratings and material selections.

- Specialized BMS Features: Implementing advanced functionalities such as passive/active heating/cooling systems, rapid charge optimization, or specific load management strategies.

Our agile design and manufacturing capabilities, backed by years of experience and adherence to ISO standards, enable us to deliver reliable, high-performance custom battery packs within competitive lead times.

Application Case Studies: Proven Performance in Action

Case Study 1: Large-Scale Energy Storage for a Petrochemical Facility

Client: Major International Petrochemical Corporation

Challenge: The client required a robust, high-capacity energy storage solution to stabilize their internal grid, manage peak demand, and provide critical backup power for sensitive process control systems during utility outages. The environment was highly corrosive and presented significant safety concerns.

Solution: We engineered and deployed a custom 1.5 MWh Battery Pack system utilizing LiFePO4 chemistry, configured for 1000V DC. The system featured a multi-layer BMS with redundancy and remote monitoring capabilities, integrated into a NEMA 4X (IP66 equivalent) stainless steel enclosure with specialized anti-corrosion coatings. The thermal management system was designed to operate reliably within an ambient temperature range of -10°C to +50°C, typical of the facility's location.

Results: The system successfully reduced peak demand charges by an average of 18% through load shifting and offered immediate, seamless backup power, preventing costly downtime during multiple grid disturbances. The robust construction ensured uninterrupted operation despite the harsh chemical environment, demonstrating exceptional reliability and contributing to significant energy saving.

Case Study 2: Off-Grid Power for Remote Water Treatment Plant

Client: Municipal Water Authority in a Remote Region

Challenge: A newly constructed water treatment plant in a geographically isolated area required a reliable, self-sustaining power source integrated with a solar PV array. The solution needed to withstand extreme weather conditions, including heavy rainfall and significant temperature swings, while ensuring continuous operation of vital pumping and filtration systems.

Solution: We provided a modular 250 kWh Battery Pack system, designed with a high IP67 rating and a robust aluminum housing for superior water and dust ingress protection. The integrated smart BMS optimized energy harvesting from the solar array and ensured efficient power delivery to the plant. The system was designed for an extended cycle life, minimizing the need for maintenance in a hard-to-reach location.

Results: The plant achieved 100% energy independence, eliminating reliance on expensive and logistically challenging diesel generators. The battery pack reliably powered critical infrastructure, ensuring uninterrupted clean water supply to the community. The system's durability and minimal maintenance requirements have significantly reduced operational costs and improved system resilience.

Frequently Asked Questions (FAQ)

- Q: What is the expected lifespan of your Battery Pack?

- A: Our LiFePO4 battery packs are designed for a long service life, typically exceeding 6,000 to 8,000 cycles at 80% Depth of Discharge (DoD) under optimal operating conditions. This translates to 10-15 years or more in most industrial applications, significantly outperforming traditional battery chemistries.

- Q: How do your battery packs handle extreme temperatures?

- A: Our battery packs are engineered with advanced thermal management systems, including active cooling or heating elements where necessary. They are designed to operate efficiently across a wide temperature range, typically from -20°C to +60°C. Custom solutions can be provided for even more extreme environmental conditions.

- Q: What safety features are integrated into your battery packs?

- A: Safety is paramount. Every battery pack includes a sophisticated Battery Management System (BMS) that provides multi-level protection against over-charge, over-discharge, over-current, short-circuit, and extreme temperatures. Our systems also feature pre-charge circuits and robust fault diagnostics.

- Q: Are your battery packs scalable?

- A: Yes, our modular design approach allows for easy scalability in both voltage and capacity. Multiple battery packs can be connected in series and/or parallel to meet specific energy storage requirements, from kilowatts to megawatts.

Lead Time, Warranty, and After-Sales Support

Lead Time and Fulfillment

Our efficient manufacturing processes and robust supply chain enable us to offer competitive lead times. For standard Battery Pack configurations, typical lead times range from 4 to 8 weeks. Custom solutions may require slightly longer, depending on complexity and specific component sourcing, usually between 8 to 14 weeks. We work closely with clients to establish realistic timelines and provide regular updates throughout the production and delivery process, ensuring on-time fulfillment.

Warranty Commitments

We stand behind the quality and reliability of our products with comprehensive warranty programs. Our industrial battery packs typically come with a warranty period of 5 to 10 years, or a specified number of cycles (e.g., 6,000 cycles at 80% DoD), whichever comes first. Specific warranty terms will be detailed in your project contract, reflecting our confidence in the longevity and performance of our solutions.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We provide extensive after-sales support to ensure optimal operation and maximize the lifespan of your battery systems. Our services include:

- Technical Assistance: A dedicated team of engineers provides remote and on-site technical support for troubleshooting, system optimization, and integration queries.

- Preventive Maintenance: Guidance and scheduled services to ensure continuous peak performance and extend product life.

- Remote Monitoring: For compatible systems, we offer advanced remote monitoring capabilities, allowing for proactive diagnostics and performance management.

- Spare Parts and Repairs: Availability of genuine spare parts and efficient repair services to minimize downtime.

- Training Programs: Comprehensive training for client staff on system operation, maintenance, and safety protocols.

Our global network of service partners ensures prompt and professional support wherever your operations are located.

Conclusion

The demand for reliable, high-performance energy storage solutions continues to accelerate across all industrial sectors. Our advanced Battery Pack technology represents the pinnacle of engineering excellence, offering unparalleled longevity, safety, and operational efficiency. By leveraging cutting-edge LiFePO4 chemistry, sophisticated BMS, and robust mechanical designs, we deliver solutions that not only meet but exceed the rigorous requirements of modern industrial applications, from petrochemical and metallurgy to water treatment and renewable energy storage. Our commitment to customization, coupled with comprehensive support and stringent quality control, ensures that our battery packs provide a strategic advantage, driving energy saving, enhancing operational continuity, and securing a sustainable future for our B2B partners.

As industries increasingly transition towards electrification and smart energy management, investing in a high-quality battery pack is not merely a purchase but a strategic decision that underpins operational resilience and long-term profitability. Partner with us to power your future with confidence and precision.

References

- International Electrotechnical Commission. (2022). IEC 62619: Secondary lithium cells and batteries for industrial applications – Safety requirements.

- Underwriters Laboratories. (2020). UL 1973: Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power, and Light Rail (LRV) Applications.

- Battolyser B.V. (2023). LiFePO4 vs. NMC: A comprehensive comparison for energy storage systems.

- United Nations Economic Commission for Europe. (2021). UN 38.3: Manual of Tests and Criteria for Lithium Batteries.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact Us

Contact Us Monitoring

Monitoring

LEARN MORE

LEARN MORE