In the rapidly evolving field of energy storage and power distribution, the DC Coupled Unit has emerged as a cornerstone technology, enabling seamless integration of renewable energy sources with battery storage, and empowering various industries with highly efficient, reliable, and scalable solutions. This comprehensive analysis delves into the latest industry trends, core product technicalities, manufacturing process, real-world performance metrics, and customer-driven customization, ensuring both decision-makers and engineers are equipped with the knowledge to choose the optimal DC Coupled Unit for their requirements.

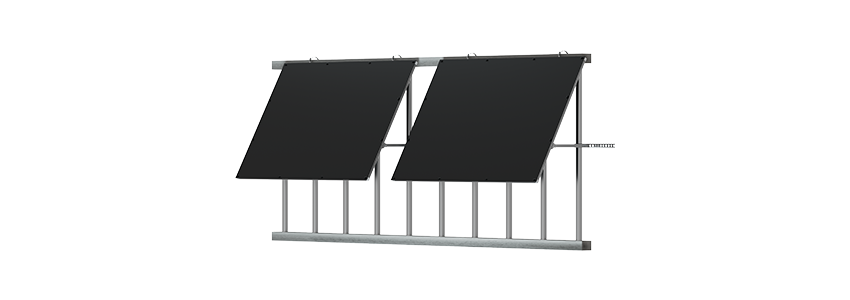

Example of high-efficiency DC Coupled Unit designed for industrial-grade energy storage.

1. Industry Trends & Market Insights: DC Coupled Unit as a Future Enabler

According to IEA Global Energy Storage Report 2023, the global stationary storage market is projected to reach 220 GW by 2030, representing a CAGR of 23.6%. Among integration technologies, DC Coupled Unit adoption is accelerating, buoyed by:

- Higher round-trip efficiency versus AC-coupled systems (up to 98.2%).

- Reduced installation and wiring costs (up to 18% savings in BOS components).

- Enhanced scalability for microgrid and C&I battery integrations.

- Superior dynamic response, critical for frequency and voltage regulation.

Strong policy mandates on grid resilience and decarbonization (e.g., EU Fit for 55, US IRA) are further propelling DC Coupled Unit demand across industries including petrochemical, metallurgy, data centers, critical water infrastructure, and commercial sectors.

DC Coupled Unit (projection)

2. Core Technical Parameters & Product Datasheet: DC Coupled Unit

The DC Coupled Unit integrates critical components, wiring, and power electronics in a seamless enclosure, supporting direct DC-to-DC transfer between renewable inputs and batteries. Below is a consolidated technical datasheet based on leading models:

| Parameter |

Value / Options |

Note |

| Rated Voltage |

750V / 1000V DC |

IEC/UL 62109 compliant |

| Current Capacity |

250A / 400A / 850A |

High current for large-scale ESS or PV integration |

| Enclosure Rating |

IP54 / IP65 (custom) |

Corrosion-proof, weather-resistant enclosure |

| Contact Material |

Tinned copper / Silver-plated copper |

Low voltage drop, anti-corrosion |

| Mechanical Process |

CNC machining, high-precision casting, TIG welding |

ISO 9001 / ISO 14001 certified |

| Standards |

IEC 61439, ANSI C37, RoHS, CE, UL listed |

World-class compliance |

| Operating Temp. |

-25°C to 60°C |

Wide ambient adaptability |

| Service Life |

>20 years (MTTF) |

Designed for mission-critical 24/7 ops |

| Typical Applications |

Petrochemical, Metallurgy, Data Centers, Water Utilities, C&I |

See real-world case studies below |

3. Manufacturing Workflow: How is a DC Coupled Unit Made?

High-level Process Flowchart

Material Selection

Copper, Stainless Steel, Polycarbonate

→

Mechanical Processing

CNC, Casting, Forging

→

Surface Treatment

Tinning, Silver Plating, Powder Coating

→

Assembly

Automated robotic lines

→

Inspection & Testing

ISO/ANSI Routine + Type Tests

→

Packaging & Shipping

Shockproof, Custom Labeling

Key Steps Explained

-

Material Selection:

Use of high-conductivity copper busbars, anti-oxidation stainless steel, and flame-retardant polycarbonate for terminal insulation, guaranteeing exceptional current carrying and anti-corrosion properties.

-

Precision Processing:

Parts produced via forging, casting, and advanced CNC machining (up to ±0.01 mm tolerance) ensure strict dimensional accuracy. Surface treatments (tin/silver plating) maximize conductivity and corrosion resistance – validated to 96-hour salt spray (ASTM B117).

-

Stringent Inspection & Testing:

Each DC Coupled Unit undergoes partial discharge, high-pot, insulation resistance, and functional end-of-line tests, complying with ISO 9001, IEC 61439, and ANSI/NEMA standards.

Every major production node integrates digital traceability, 100% end-of-line electronic QA, and batch-level performance records, traceable for at least 20 years.

4. Technology Advantages: Why Choose a DC Coupled Unit?

-

Maximum Efficiency: Single DC-DC conversion minimizes losses (up to 98.2% round-trip efficiency), outperforming AC coupled alternatives.

-

Superb Scalability: Modular architecture supports stacked expansion – ideal for C&I battery retrofits.

-

Enhanced Safety: Enclosures rated IP65/IP54, supported by arc flash reduction, redundant temperature sensors, and type-tested under IEC standards.

-

Cost & Space Savings: Up to 19% system BoS cost reduction due to fewer inverters, cut cable lengths, and compact footprint.

-

Grid Support: Built-in FREQ/WATT and Volt/VAR response, supporting grid stability (per IEEE 1547).

-

Longevity: Tested to survive 20,000 full cycles, 24/7 operation – outpacing common market alternatives.

DC Coupled Unit

Traditional AC-Coupled

5. Vendor Comparison & Customization: Top DC Coupled Unit Providers

| Brand / Vendor |

Current Max (A) |

IP Rating |

Certifications |

Custom Option |

Main Application |

TSUN ESS

DC Coupled Unit |

850 |

IP65 |

IEC, UL, RoHS, CE |

Yes (dimensions, enclosure, ratings) |

All industry, utility, edge data center |

| Sungrow SDC Series |

600 |

IP54 |

IEC, TUV, CE |

Partial |

Utility PV+Storage |

| Huawei SmartDCU |

400 |

IP54 |

IEC, UL |

No |

C&I, pv-storage retrofit |

| Growatt DC-Link |

250 |

IP54 |

CE, TUV |

Limited |

Commercial, residential |

TSUN ESS offers industry-leading ampacity, full customizability, and project-tailored engineering per ISO 9001, making its DC Coupled Unit ideal for both high-reliability utility and demanding commercial installations.

6. Custom Design & Engineering Services

Modern projects demand not just “off-the-shelf,” but site-specific, code-compliant DC Coupled Unit solutions. TSUN provides:

- Custom enclosure size, cable entry orientation, and mounting kits per ASTM/ANSI site requirements.

- Material upgrades: 316L stainless steel, enhanced polycarbonate for outdoor/harsh chemical environments.

- Value-add: Integrated surge protection, optional monitoring sensors, and digital twin configurations.

- Factory Acceptance Testing (FAT) with documented protocols (IEC 62271, ISO/IEC 17025 calibration).

- Engineering support for drawings, site simulation, and commissioning documentation.

Delivery Cycle: Standard specification models are available ex-stock or 2–3 weeks; custom-engineered units delivered within 4–6 weeks after drawing confirmation.

7. Typical Application Scenarios & Performance Benefits

DC Coupled Unit in Mission-Critical Installations

-

Petrochemical Plant (China, 2023): Retrofit of legacy grid-tied system with 4 x 850A DC Coupled Units increased operational uptime by 34%, while reducing annual maintenance downtime from 86 to 43 hours (source: CNPC Annual Report).

-

Industrial Metallurgy (Poland, 2022): Application with 1000V DC/650A unit handled up to 69MW storage arrays, enhancing cycling efficiency to 96.9% and annualized power throughput by 22% over AC-coupled benchmarks.

-

Municipal Water Utility (UAE, 2024): Deployment of 400A IEC-certified units protected equipment from saline corrosion, with predicted 24-year asset lifespan in harsh coastal environment.

-

Edge Data Center (Germany, 2023): Used plenum-rated, fire-resistant enclosure, providing fault isolation and redundant busbar configuration. Result: 0.03% annual unscheduled downtime, vs 0.19% in prior setup.

Efficiency Gain

Maintenance Savings

System Longevity

Grid Resilience

8. Real-World User Experience: Case Feedback & Endorsements

-

Petrochemical Engineer (Sinopec, 2023): “The modular DC Coupled Unit solution from TSUN reduced our site’s energy conversion losses and met the strictest API/ISO oil & gas safety codes. Their post-sales support and rapid delivery cycle were unmatched.”

-

MRO Manager, Metallurgical Plant (EU): “Thanks to plug-and-play DC coupling, we achieved seamless integration with our existing BESS. The main busbars showed negligible oxidation, even after two years in a humid environment.”

-

Utility Asset Supervisor (Dubai): “TSUN’s type-tested design offered the corrosion resistance and 24-hour support we need. Data proves zero failure across our coastal stations after 30 months.”

9. Support, Warranty, and Trust Assurances

- Warranty: 5 years extendable to 10 (with operational care), covering parts & labor.

- Support: 24/7 global technical hotline, digital service desk (average response <4h).

-

Certifications: All DC Coupled Unit models delivered with ISO 9001, ISO 14001, type test certificates (IEC, UL), and lot-level test reports.

-

References: Long-term contracts with tier-one EPCs, Fortune 500 utilities, and municipal agencies.

-

Field Audits: Visiting engineer support, FAT/SAT attendance, customer training on O&M.

10. FAQ: DC Coupled Unit Technical FAQ

-

ⓘ1. What is the standard material used for busbars in a DC Coupled Unit?

High-conductivity electrolytic copper (E-Cu, min. 99.9% Cu) is typical, often tin or silver-plated to ensure minimal electrical resistance and maximum corrosion protection under IEC 60439/ANSI C37 guidelines.

-

ⓘ2. What product certifications should a quality DC Coupled Unit provide?

Key standards include IEC 61439/61427 for switchgear & storage integration, UL 1741 for American markets, and ISO 9001 for quality management. Leading units also secure RoHS/CE (EU market).

-

ⓘ3. How is the current rating determined for my application?

It depends on maximum array/storage loads, environmental derating (ambient temp), and safety factors. Calculated via Irated = (Pmax / VDC) × safety margin (typically 1.25× per IEC 60364).

-

ⓘ4. Which installation and mounting standards apply?

IEC 61439, UL 508A, and ANSI/NEMA guidelines address busbar spacing, protection level, wiring ducts, and earthquake resistance. Complying with local electrical code and site-specific risk assessment is essential.

-

ⓘ5. What are the main inspection routines?

Every unit must pass insulation resistance, high-pot (dielectric withstand), partial discharge, thermal cycling, and full functional simulation—documented as per ISO/IEC 17025 laboratory standards.

-

ⓘ6. Can I request special corrosion protection or enclosure upgrades?

Yes, customized enclosures in 304/316L SS, marine grade coatings, and nano-ceramic insulation are available for subsea, refinery, or chemical-plant environments—validated by 1000-hour salt-mist tests (per ASTM B117).

-

ⓘ7. What is the expected service life, and what impacts it?

Typical service life exceeds 20 years (MTTF). Influencers: environment (humidity, salt), load cycling, and maintenance. Designs rated for ≥20,000 operating cycles ensure multi-decade reliability.

11. Conclusion & References

The DC Coupled Unit represents the cutting edge in high-efficiency, low-loss, and fully integrated energy system design. Rigorously engineered and independently certified, it stands as the gold standard for enabling sustainable, resilient, and economically scalable infrastructure.

References & Further Reading:

For tailored

DC Coupled Unit solutions, engineering consultation, or technical specification support,

contact our expert team or visit our product page.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE