LEARN DETAILS

LEARN DETAILSEasy Solar Kit

Monitoring & Accessory

- Monitoring & Accessory

- Smart Meter

MH2000/MH1000

- Power meter

MH2000/MH1000

- DTU

MH2000/MH1000

- Hang on Balcony (DIY)

-

ESK Balcony Air Vertical

ESK400/800-Air(V)

-

ESK Balcony Air Angled

ESK400/800-Air(A)

-

ESK Balcony Vertical

ESK400/800-BV

-

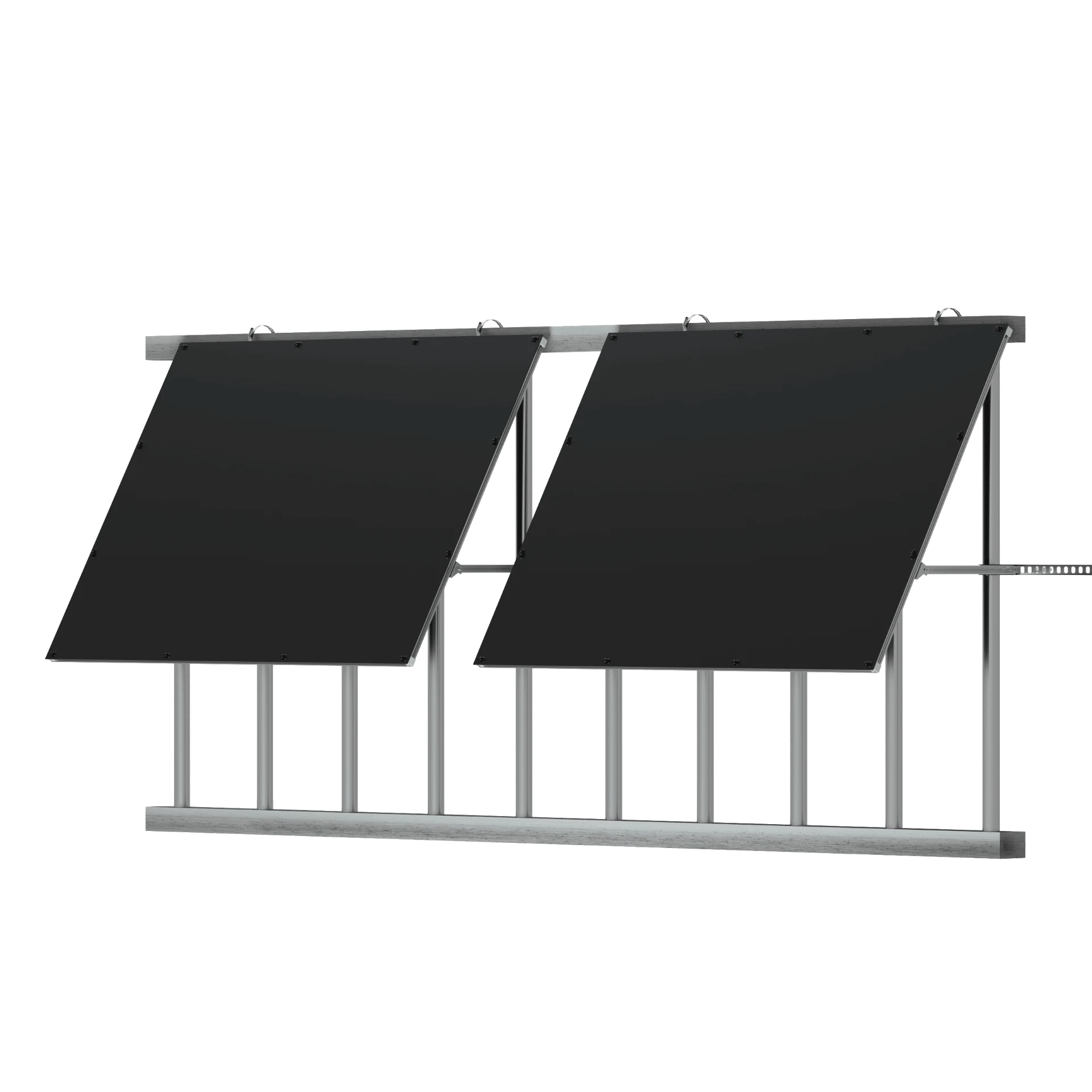

ESK Balcony Angled

ESK400/800-BA

- On the Ground (Ready to Use)

-

ESK Pop-Up

ESK400/800-P

- All Scenarios (DIY)

-

ESK Universal

ESK400/800-U

-

ESK Transformer

ESK400/800-T

- Micro Storage System

-

SolarTrunk (Micro Hybrid Storage Unit)

MSU2000/2000DE | 2 kWh - 10 kWh

-

PowerTrunk (Micro AC Coupled Unit)

MAU2000/2000DE | 2 kWh - 10 kWh

-

SolarCan (DC Coupled Unit)

DCU2000Lite | 2 kWh - 10 kWh

-

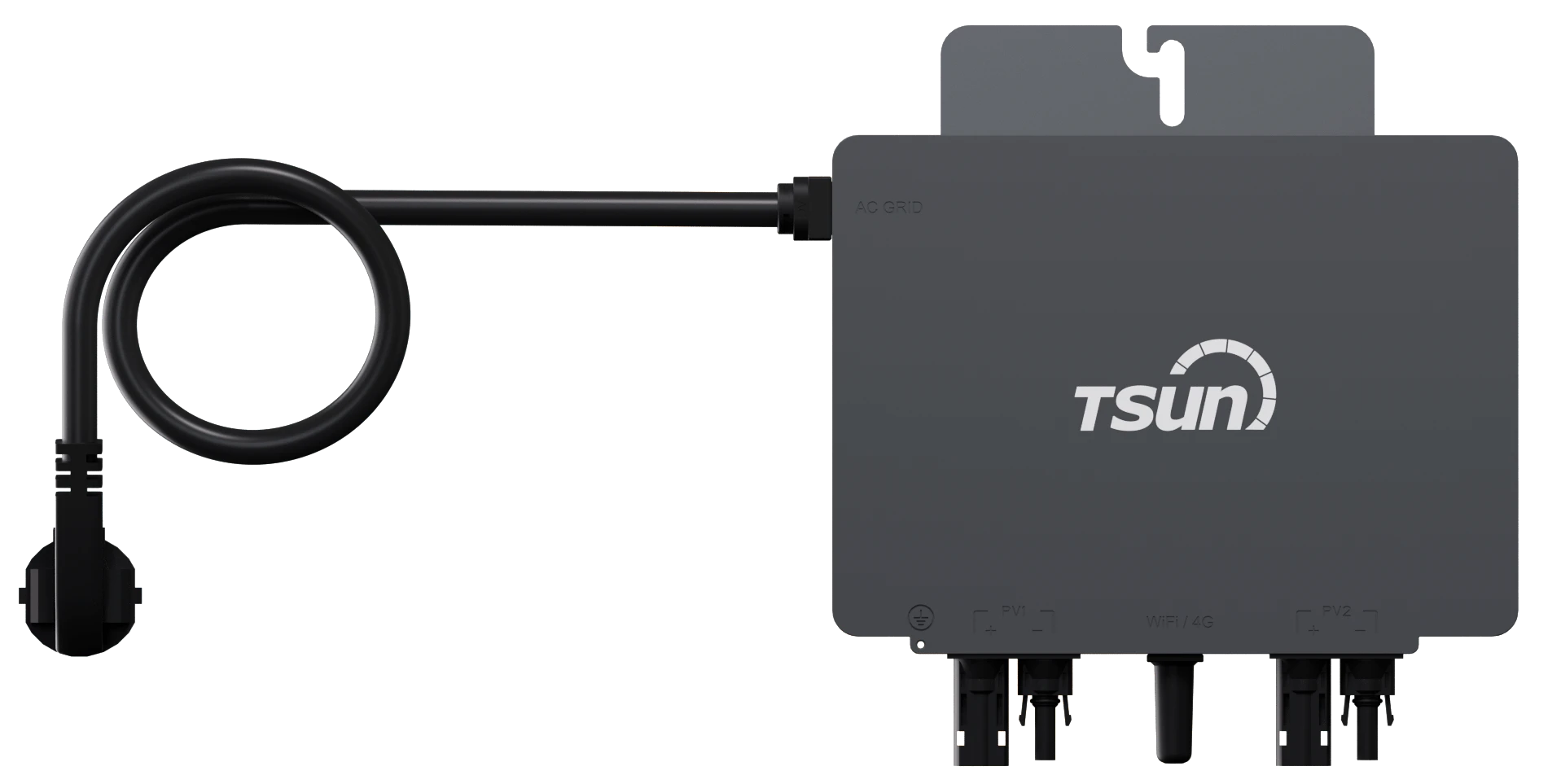

Hybrid Microinverter

MH2000/MH1000

- Residential Storage System

-

AC Coupled Storage Unit

ACU3.0/3.6/4.0/4.6/5.0/6.0K | 5 kWh-20 kWh

- Monitoring & Accessory

-

Smart Meter

Built-in Wi-Fi

-

Power meter

Built-in RS485/CT

-

DTU

Built-in Wi-Fi & RS485 & RJ45

On Grid System — Easy Solar Kit

Easy Solar Kit, which integrates PV module, microinverter, DIY bracket and cables, is designed for a variety of applications, can be installed on balcony, garden, flat roof and even wall.

LEARN DETAILS

LEARN DETAILS

Storage System — SolarCan(DC Coupled Unit) & Easy Solar Kit

This solution, Solar Module + SolarCan + Balcony Microinverter, is typically used as a micro energy storage solution for small household, conventional balconies, courtyards, family carports, and other plug & play scenarios.

LEARN DETAILS

LEARN DETAILS

Storage System — Hybrid Microinverter & Stackable Battery Pack & Easy Solar Kit

The integrated configuration of solar modules, hybrid microinverters, and batteries serves as a versatile hybrid energy storage solution, predominantly deployed in diverse residential settings, including balconies, courtyards, and house carports.for small household, conventional balconies, courtyards, family carports, and other micro systems.

LEARN DETAILS

LEARN DETAILS

SolarTrunk(Micro Hybrid Storage Unit) & Easy Solar Kit

The SolarTrunk is designed to store surplus electrical energy within the battery and discharge it as required. This integrated configuration of solar modules and the SolarTrunk functions as a versatile hybrid energy storage solution, predominantly deployed in diverse residential settings, including balconies, courtyards, and house carports

LEARN DETAILS

LEARN DETAILS

PowerTrunk(Micro AC Coupled Unit) & Easy Solar Kit

The PowerTrunk is a key component of the micro hybrid storage system, which integrates both the energy storage inverter and the battery pack.

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact Us

Contact Us Monitoring

Monitoring

LEARN MORE

LEARN MORE