Industry Trends and Market Demand for DC Coupled Units

The global energy landscape is undergoing a profound transformation, driven by an urgent need for decarbonization, increased energy independence, and grid modernization. Central to this evolution is the rapid expansion of renewable energy sources, particularly solar photovoltaic (PV), and the indispensable role of energy storage systems (ESS). As the integration of intermittent renewables scales up, the demand for efficient, reliable, and flexible power conversion solutions has skyrocketed. This is where the DC Coupled Unit emerges as a pivotal technology.

Market analysis indicates a robust growth trajectory for battery energy storage, with projections showing a compound annual growth rate (CAGR) exceeding 25% for the next decade. This growth is fueled by declining battery costs, supportive government policies, and the increasing viability of solar-plus-storage solutions across residential, commercial, and utility-scale sectors. A DC Coupled Unit, by integrating PV generation and battery storage directly on the DC bus, offers significant advantages in terms of efficiency, cost-effectiveness, and system flexibility, making it a preferred architecture for modern ESS deployments.

Key trends driving this adoption include the rise of hybrid power plants, the need for enhanced grid ancillary services (e.g., frequency regulation, voltage support), the expansion of microgrids, and the growing demand for EV charging infrastructure that leverages renewable energy. The inherent efficiency gains of DC coupling, by minimizing conversion losses, directly translate to lower Levelized Cost of Energy (LCOE) for end-users and improved return on investment for developers and operators.

Understanding the DC Coupled Unit: Technical Overview and Working Principle

A DC Coupled Unit, at its core, is an integrated power electronics device designed to efficiently manage and convert DC power from multiple sources, typically solar PV arrays and battery energy storage systems, for various applications, including direct DC loads, grid connection, or AC loads via an inverter. Unlike traditional AC coupled systems that convert PV DC power to AC before reconverting it back to DC for battery storage, a DC coupled architecture routes all DC power to a common DC bus.

The primary components within a sophisticated DC Coupled Unit typically include:

- Maximum Power Point Tracking (MPPT) Converters: These essential components optimize the power output from PV arrays by continuously adjusting to varying solar irradiance and temperature conditions. Advanced MPPT algorithms ensure that the PV system operates at its peak efficiency, maximizing energy harvest.

- Bi-directional DC-DC Converters: These facilitate the seamless flow of power between the DC bus and the battery bank. They manage battery charging from the PV array or grid (via an inverter) and battery discharging to power loads or export to the grid. This component often incorporates sophisticated battery management system (BMS) communication protocols (e.g., CAN bus, RS485) to ensure safe and optimized battery operation.

- System Controller and Communication Module: This intelligent core manages all power flows, implements energy management strategies, monitors system performance, and communicates with external systems (e.g., grid operators, home energy management systems, SCADA). Remote monitoring and control capabilities are standard, often via Ethernet or cellular networks.

- Protection Circuitry: Comprehensive over-voltage, under-voltage, over-current, short-circuit, and over-temperature protection mechanisms safeguard the unit and connected assets. Integrated surge protection devices (SPDs) are also critical.

The working principle hinges on the intelligent control of these components. When solar panels generate power, the MPPT converter ensures maximum energy extraction. This DC power can then be directed to charge the batteries via the bi-directional DC-DC converter, supply DC loads, or, if an inverter is connected to the DC bus, convert to AC for grid export or AC loads. The bi-directional converter enables dynamic power allocation, allowing the system to prioritize charging, discharging, or direct consumption based on programmed strategies, real-time energy prices, or grid conditions.

Manufacturing Process and Quality Assurance

The production of a high-performance DC Coupled Unit demands a meticulous manufacturing process combined with stringent quality assurance protocols to ensure reliability, efficiency, and longevity. While not involving traditional casting or forging, the process is highly sophisticated for electronic systems:

- Component Sourcing & Verification: Begins with selecting high-grade, certified electronic components (IGBTs, MOSFETs, capacitors, microcontrollers) from ISO 9001 certified global suppliers. Each batch undergoes rigorous incoming quality control (IQC) to verify specifications and authenticity, minimizing defect rates from the outset.

- Printed Circuit Board (PCB) Assembly: Advanced automated SMT (Surface Mount Technology) lines precisely place and solder thousands of components onto multi-layer PCBs. This is followed by automated optical inspection (AOI) to detect any solder defects or component misalignments. Hand soldering is performed for larger through-hole components with highly skilled technicians.

- Enclosure Fabrication & Integration: Robust enclosures, often constructed from high-grade aluminum alloys or galvanized steel, are precision-machined (e.g., via CNC machining for vents, mounting points, and cable glands) to ensure precise fit and optimal thermal management. Materials are chosen for their corrosion resistance, crucial for industrial and outdoor applications in industries such as petrochemical, metallurgy, and water supply & drainage. The enclosures are designed to achieve specific IP ratings (e.g., IP65) for dust and water ingress protection.

- Module Assembly & Wiring: Individual PCB assemblies, power modules, and cooling systems are meticulously integrated into the enclosure. High-quality, properly rated wiring harnesses are installed, ensuring optimal current flow and minimal losses, with every connection checked for torque and continuity.

- Firmware Integration & Calibration: The embedded control software, which defines the intelligence and functionality of the DC Coupled Unit, is loaded and calibrated. This includes precise calibration of sensors for voltage, current, and temperature, ensuring accurate readings and optimal control responses.

- Rigorous Testing Standards: Each unit undergoes a multi-stage testing process adhering to international standards such as ISO (for quality management), IEC (for electrical safety and performance), and relevant regional standards like UL (North America) or TUV (Europe). This includes:

- Functional Testing: Verifying all operating modes, power conversion efficiencies, and communication protocols under simulated real-world conditions.

- Stress Testing (Burn-in): Units operate at full load under elevated temperatures for extended periods to identify early-life failures and ensure long-term reliability.

- Environmental Testing: Exposure to extreme temperatures, humidity, and vibration to confirm resilience in diverse operational environments.

- Safety & Compliance Testing: Dielectric strength, insulation resistance, grounding integrity, and electromagnetic compatibility (EMC) tests to ensure compliance with safety regulations.

- Final Quality Assurance & Packaging: A final comprehensive inspection ensures aesthetic quality, correct labeling, and proper packaging for secure transit.

This stringent process ensures an exceptional service life, typically exceeding 10-15 years, and guarantees robust performance in demanding environments, delivering advantages like energy saving and superior corrosion resistance due to material and design choices.

Technical Specifications and Performance Parameters

The performance of a DC Coupled Unit is defined by its robust technical specifications, which dictate its compatibility, efficiency, and operational capabilities within various energy storage architectures. Below is a representative table of key parameters for a high-performance DC Coupled Unit, reflecting industry best practices and typical offerings:

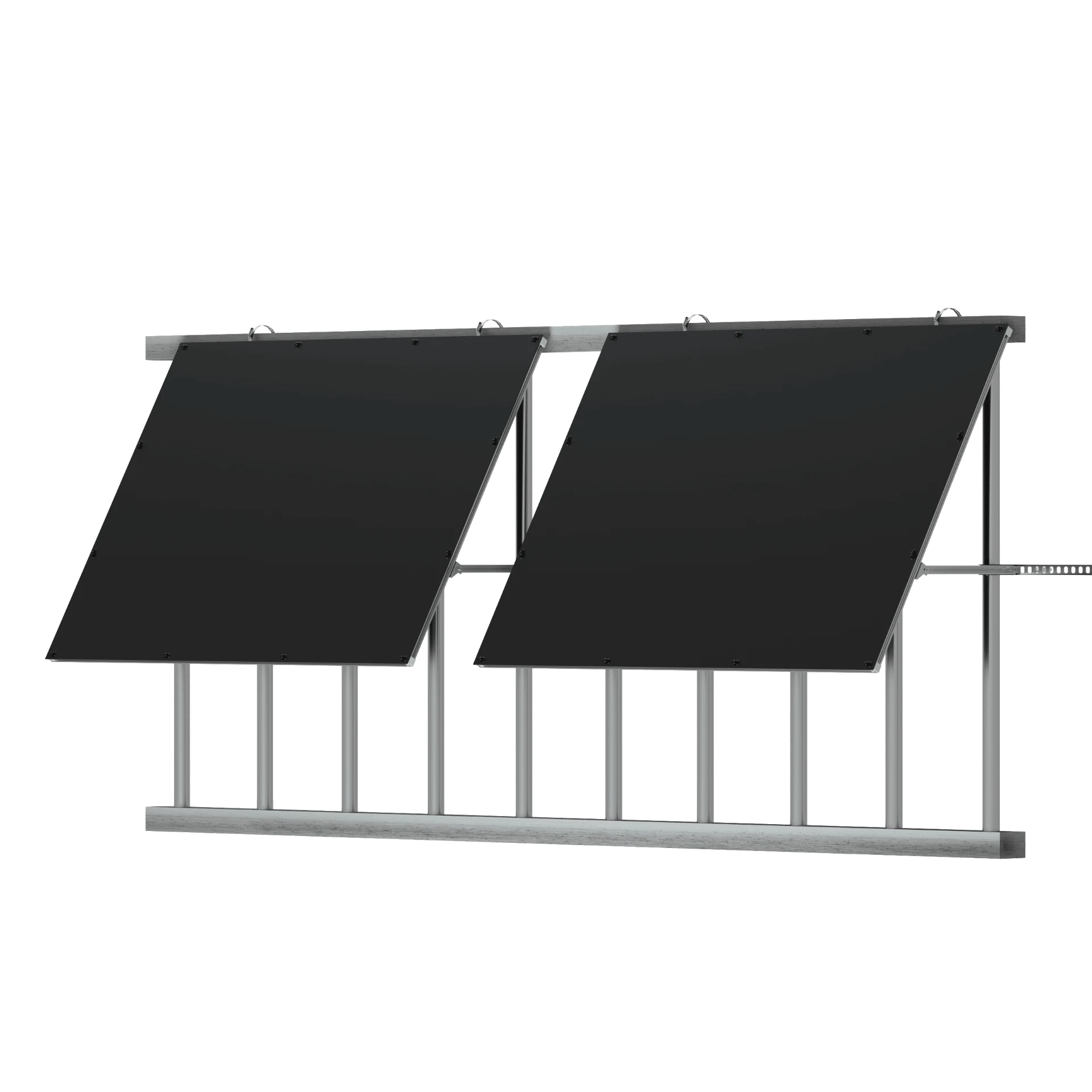

![Efficient [DC Coupled Unit] for Solar Battery Storage Systems Efficient [DC Coupled Unit] for Solar Battery Storage Systems](https://www.tsun-ess.com/images/auto/uploads-DCU1000850X3000.jpg)

Typical DC Coupled Unit Technical Specifications (Representative Data)

| Parameter |

Value/Range |

Description |

| Nominal Power Rating |

50 kW - 500 kW (Modular) |

Total power handling capacity for charge/discharge. |

| Max. PV Input Voltage (Voc) |

1000 V - 1500 V DC |

Maximum open circuit voltage from PV array. |

| MPPT Voltage Range |

500 V - 1450 V DC |

Operating voltage range for PV MPPT. |

| Number of MPPTs |

2-12 (Configurable) |

Independent Maximum Power Point Trackers for PV strings. |

| Battery Voltage Range |

400 V - 1000 V DC |

Compatible battery system voltage. |

| Max. Battery Charge/Discharge Current |

100 A - 600 A (Configurable) |

Maximum current for battery charging/discharging. |

| Max. Efficiency (PV to Battery) |

> 98.5% |

Peak conversion efficiency. |

| Communication Interfaces |

CAN, RS485 (Modbus RTU), Ethernet (Modbus TCP/IP, SNMP) |

Protocols for BMS, external control, and monitoring. |

| Operating Temperature Range |

-25°C to +60°C |

Environmental operating limits. |

| Ingress Protection (IP) Rating |

IP65 |

Dust-tight and protected against water jets. |

| Cooling |

Forced air cooling (Intelligent fan control) |

Effective thermal management for component longevity. |

| Certifications |

CE, IEC 62109, UL 1741, TUV |

Compliance with international safety and performance standards. |

Key Technical Advantages of DC Coupled Units

The architectural design of a DC Coupled Unit offers several significant advantages over traditional AC coupled or separate component systems, particularly for solar-plus-storage applications:

- Higher System Efficiency: By connecting PV and batteries directly to a common DC bus, the system avoids multiple DC-AC and AC-DC conversions inherent in AC coupled systems. This reduction in conversion stages minimizes energy losses, leading to higher overall system efficiency, which can exceed 98.5% for the DC-DC conversion stage. For example, a typical AC coupled system might lose 5-10% more energy during storage and retrieval cycles compared to a DC coupled system.

- Optimized Battery Charging: A DC Coupled Unit can charge batteries directly from the PV array with optimal voltage and current regulation, often providing higher charging efficiency and better battery health management, extending the battery's service life. The direct connection bypasses unnecessary inverter stages.

- Enhanced Flexibility and Control: The integrated nature allows for granular control over power flow. Operators can easily prioritize direct consumption, battery charging, or grid export based on dynamic conditions, energy tariffs, or system requirements. This flexibility is crucial for advanced energy management strategies like peak shaving, load shifting, and demand response.

- Simplified System Design and Installation: Consolidating multiple functionalities into a single unit reduces the complexity of system design, requiring fewer components, less wiring, and a smaller footprint. This simplifies installation, reduces labor costs, and minimizes potential points of failure.

- Improved Grid Support Capabilities: With fast response times and precise power control, DC coupled systems are well-suited for providing essential grid ancillary services. They can rapidly inject or absorb power to support grid stability, frequency regulation, and voltage control, making them valuable assets for grid operators.

- Black Start and Off-Grid Capability: Many DC Coupled Units, especially when paired with suitable inverters, can provide black start capability, allowing the system to restart and operate independently in the event of a grid outage. This is vital for critical infrastructure and remote off-grid applications.

- Scalability: Modular designs allow for easy expansion of both PV and battery capacities by adding more DC Coupled Units or connecting larger arrays/battery banks, future-proofing investments.

Application Scenarios

The versatility and efficiency of the DC Coupled Unit make it an ideal solution for a diverse range of energy applications, from small commercial installations to large-scale utility projects.

- Commercial and Industrial (C&I) Solar-plus-Storage: Businesses leverage DC Coupled Units to maximize self-consumption of solar energy, reduce peak demand charges, and benefit from arbitrage by charging batteries during off-peak hours and discharging during expensive peak times. This directly contributes to energy saving and operational cost reduction for facilities like manufacturing plants, data centers, and large retail outlets.

- Off-Grid and Hybrid Power Systems: For remote locations or critical infrastructure requiring energy independence, DC coupled systems provide robust and reliable power. They seamlessly integrate solar PV, battery storage, and often a generator (hybrid setup) to ensure continuous power supply, particularly important in sectors like telecommunications, remote mining, and agricultural facilities.

- Microgrids: In both grid-connected and islanded microgrids, DC Coupled Units are foundational. They facilitate the efficient management of distributed energy resources (DERs), enhance resilience, and allow for active power quality management, crucial for campuses, military bases, and islands seeking energy autonomy.

- Utility-Scale Battery Energy Storage Systems (BESS): For large-scale grid applications, DC coupled solutions enable greater efficiency in energy shifting, frequency regulation, voltage support, and renewable energy firming. They are key components in large solar farms co-located with battery storage, improving the predictability and dispatchability of renewable generation.

- Electric Vehicle (EV) Charging Infrastructure: Integrating solar PV and battery storage with EV charging stations via a DC Coupled Unit allows for dynamic load management, reducing stress on the grid, optimizing the use of renewable energy, and providing faster charging capabilities without necessitating massive grid upgrades.

Vendor Comparison and Selection Criteria

Selecting the right DC Coupled Unit vendor is a critical decision for B2B clients, impacting system performance, long-term reliability, and total cost of ownership. Beyond initial product specifications, key considerations include the vendor's experience, support infrastructure, and commitment to innovation.

Vendor Comparison: Key Differentiators for DC Coupled Units

| Feature/Criterion |

Leading Provider (e.g., TSUN) |

Generic Competitor (Average) |

| Conversion Efficiency |

>98.5% (Peak PV-to-Battery) |

96-98% |

| Battery Compatibility |

Broad compatibility (various Li-ion chemistries), CAN/RS485 BMS integration |

Limited to specific battery brands/models |

| Scalability & Modularity |

Highly modular design, easy parallel connection for MW-scale systems |

Fixed capacities, complex scaling |

| Environmental Rating |

IP65/NEMA 4X, robust for harsh outdoor conditions |

IP54/IP55, requiring sheltered installation |

| Monitoring & Control |

Advanced cloud-based EMS, real-time data, remote diagnostics |

Basic local monitoring, limited remote access |

| Customization Options |

High flexibility in voltage, power, communication protocols, mechanical design |

Standardized products only |

| Warranty & Support |

Comprehensive 5-10 year warranty, global technical support, rapid response |

Shorter warranty, regional support, slower response times |

When evaluating vendors, consider factors such as:

Proven Track Record: Look for vendors with years of specialized experience in power electronics and energy storage. A strong portfolio of successful installations and partner clients demonstrates reliability.

Certifications: Verify adherence to international standards (e.g., ISO, IEC, UL) which indicate product quality, safety, and environmental responsibility.

Technical Support & Service: A robust global service network and responsive technical support are paramount for maximizing uptime and addressing any operational challenges swiftly.

Customized Solutions for Specific Needs

While standard DC Coupled Unit products offer broad utility, many industrial and utility-scale projects have unique requirements that necessitate customized solutions. Leading manufacturers understand this need and provide extensive engineering and design services to tailor units to specific project parameters.

Customization options for a DC Coupled Unit can include:

- Voltage and Power Adjustments: Tailoring input and output voltage ranges, as well as overall power ratings, to perfectly match specific PV array configurations or battery bank characteristics.

- Communication Protocol Integration: Adapting the unit to seamlessly communicate with existing energy management systems (EMS), SCADA systems, or specialized Battery Management Systems (BMS) through various protocols beyond standard CAN/RS485/Ethernet.

- Environmental Hardening: Designing enclosures and internal components for extreme operating conditions, such as ultra-low or high temperatures, high humidity, corrosive atmospheres (e.g., coastal or chemical plant environments), or areas prone to high seismic activity. This can include specialized coatings for corrosion resistance or advanced liquid cooling systems.

- Mechanical Design Modifications: Customizing physical dimensions, mounting arrangements, or cable entry points to fit into constrained spaces or integrate with existing infrastructure.

- Feature Additions: Integrating specialized functionalities like advanced grid-forming capabilities, reactive power compensation, or specific demand-side management algorithms.

Engaging with a vendor that offers robust R&D capabilities and a dedicated engineering team ensures that a customized DC Coupled Unit meets precise performance targets while maintaining the highest standards of reliability and safety. This collaborative approach minimizes integration risks and optimizes project outcomes for specialized applications.

Application Case Studies & Customer Experience

Real-world implementations underscore the tangible benefits of integrating a DC Coupled Unit into modern energy infrastructure. Here are illustrative examples demonstrating their impact:

Case Study 1: Peak Demand Reduction for a Commercial Cold Storage Facility

A large cold storage facility faced significant electricity costs due to high peak demand charges. By integrating a 500 kW solar PV array with a 1 MWh battery energy storage system, managed by a high-efficiency DC Coupled Unit, the facility achieved substantial savings. The system automatically charges batteries during off-peak solar generation and discharges them during peak demand periods, effectively shaving 30% off the facility's peak load. This resulted in an estimated annual saving of over $150,000, achieving ROI in less than 4 years.

"Our DC Coupled Unit has been a game-changer. The seamless integration of solar and storage has not only reduced our operational costs dramatically but also provided a reliable backup for critical cooling systems." - Facilities Manager, Global Cold Chain Logistics.

Case Study 2: Enhancing Resilience for a Remote Island Microgrid

A remote island community previously reliant on diesel generators aimed for 100% renewable energy. A microgrid project combined 2 MW of solar PV, 4 MWh of battery storage, and advanced DC Coupled Units. These units managed the intermittency of solar generation, providing stable power to the community and facilitating black start capabilities. The high efficiency of the DC coupled architecture significantly reduced diesel consumption by over 90%, leading to environmental benefits and substantial fuel cost savings.

"Reliable power without the constant drone of generators or fuel deliveries has transformed our island. The DC Coupled Units are at the heart of our energy independence." - Chief Engineer, Island Utility Cooperative.

Case Study 3: Grid Stability and Ancillary Services in a Utility-Scale Solar Farm

A 100 MW solar farm integrated with a 30 MW/60 MWh BESS deployed multiple high-capacity DC Coupled Units. These units enabled the combined facility to provide frequency regulation and voltage support services to the national grid, enhancing grid stability. The system's rapid response time and precise control capabilities, facilitated by the DC coupled architecture, allowed the solar farm to participate profitably in ancillary service markets, generating additional revenue streams beyond energy sales.

Ensuring Trust: Certifications, Support, and Warranty

Building long-term partnerships in the B2B sector hinges on demonstrating unwavering commitment to quality, reliability, and customer satisfaction. This is achieved through adherence to international standards, robust support infrastructure, and transparent warranty policies.

Authoritative Certifications and Industry Recognition

Our DC Coupled Units are designed and manufactured under the strictest quality management systems, certified to ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). Product safety and performance are validated by leading independent certification bodies, including CE (European Conformity), IEC (International Electrotechnical Commission) standards such as IEC 62109 for power converters, UL (Underwriters Laboratories) for North American markets (e.g., UL 1741), and TUV SUD/Rheinland. These certifications affirm product quality, safety, and compliance with global regulatory requirements. With over a decade of experience in power electronics, we have established ourselves as a trusted partner for numerous leading integrators and project developers worldwide.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a DC Coupled Unit order?

- A: Standard units typically have a lead time of 4-6 weeks, depending on volume. Customized solutions may require 8-12 weeks for design, manufacturing, and testing. We maintain agile production lines and robust supply chain management to ensure timely fulfillment.

- Q: How does a DC Coupled Unit handle different battery chemistries?

- A: Our units are designed for broad compatibility with various lithium-ion battery chemistries (e.g., LFP, NMC) and lead-acid batteries, provided they adhere to specified voltage ranges. Integration typically occurs via CAN bus or RS485 communication with the battery's BMS for optimal charge/discharge control.

- Q: Is remote monitoring and control available?

- A: Yes, all our units feature integrated communication modules supporting Ethernet and optionally cellular connectivity. This enables real-time performance monitoring, remote diagnostics, firmware updates, and control through a secure cloud-based platform or integration into existing SCADA systems.

Warranty Commitments

We stand behind the quality and reliability of our products with a standard 5-year product warranty. Extended warranty options, up to 10 years, are available upon request, providing clients with enhanced peace of mind and long-term investment protection. Our warranty covers material defects and workmanship under normal use and service conditions.

Comprehensive Customer Support

Our commitment to our partners extends beyond product delivery. We offer multi-tiered customer support, including:

- Dedicated Technical Support: A team of experienced engineers is available for technical consultations, troubleshooting, and system optimization.

- Online Resources: Comprehensive documentation, user manuals, firmware updates, and FAQs are accessible via our partner portal.

- Global Service Network: With regional service centers and trained field engineers, we ensure rapid response and on-site support for critical installations worldwide.

- Training Programs: We provide technical training for installers and operators to ensure safe and efficient deployment and operation of our units.

Conclusion

The DC Coupled Unit represents a cornerstone technology for the future of renewable energy integration and energy storage. Its inherent advantages in efficiency, flexibility, and streamlined system architecture address critical demands of modern power systems. As the energy transition accelerates, the strategic deployment of high-performance, reliable, and intelligently managed DC coupled solutions will be paramount for maximizing the value of solar assets, enhancing grid resilience, and driving the global shift towards a sustainable energy future. Partnering with an experienced and reputable manufacturer that prioritizes engineering excellence, robust quality control, and comprehensive customer support ensures that projects leverage the full potential of this transformative technology.

Authoritative References

- International Energy Agency (IEA). Renewable Energy Market Update. (Access via IEA.org)

- BloombergNEF. Energy Storage Outlook. (Access via BNEF.com)

- National Renewable Energy Laboratory (NREL). Solar-plus-Storage System Design and Analysis. (Access via NREL.gov)

- Institute of Electrical and Electronics Engineers (IEEE) Transactions on Power Electronics.

- European Commission Joint Research Centre. Battery Energy Storage System Report. (Access via ec.europa.eu/jrc)

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

![Efficient [DC Coupled Unit] for Solar Battery Storage Systems Efficient [DC Coupled Unit] for Solar Battery Storage Systems](https://www.tsun-ess.com/images/auto/uploads-DCU1000850X3000.jpg)

LEARN MORE

LEARN MORE