Industry Trends in Distributed Solar Energy

The global energy landscape is undergoing a transformative shift, marked by an accelerating transition towards distributed renewable energy sources. Photovoltaic (PV) systems, particularly those deployed in residential and commercial sectors, are at the forefront of this evolution. Factors such as declining system costs, advancements in energy storage, and governmental incentives for self-consumption and grid resilience are driving unprecedented growth. Industry analyses consistently indicate that distributed PV capacity will continue its exponential expansion, with projections showing annual global installations potentially reaching over 250 GW by 2027. This growth necessitates continuous innovation in power electronics, especially in inverter technologies that optimize energy harvest, enhance system safety, and integrate seamlessly with smart grids.

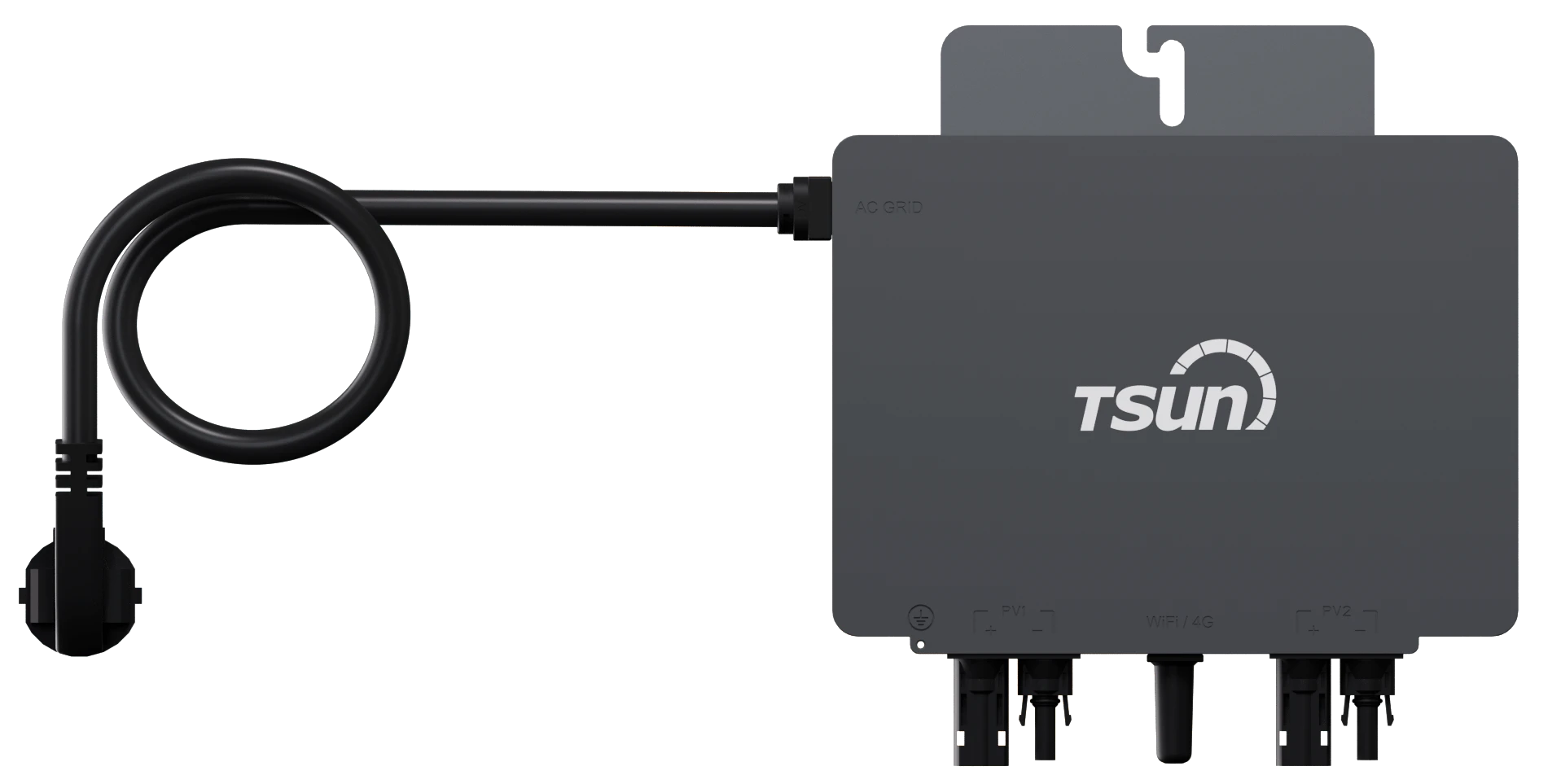

Microinverters have emerged as a superior solution for distributed generation, offering module-level power optimization that string inverters cannot match. This granular control effectively mitigates losses from shading, panel degradation mismatch, and soiling, leading to significantly higher energy yields. The market trend is moving towards more integrated, powerful, and cost-effective microinverter designs. A prime example of this innovation is the GEN3 Microinverter 2-in-1. This advanced unit encapsulates the functionality for two solar modules within a single compact enclosure, delivering a critical balance between panel-level optimization and streamlined installation. This design directly addresses the industry's need for lower Balance of System (BOS) costs, enhanced system reliability, and greater ease of deployment, solidifying its position as a pivotal technology in the modern solar ecosystem.

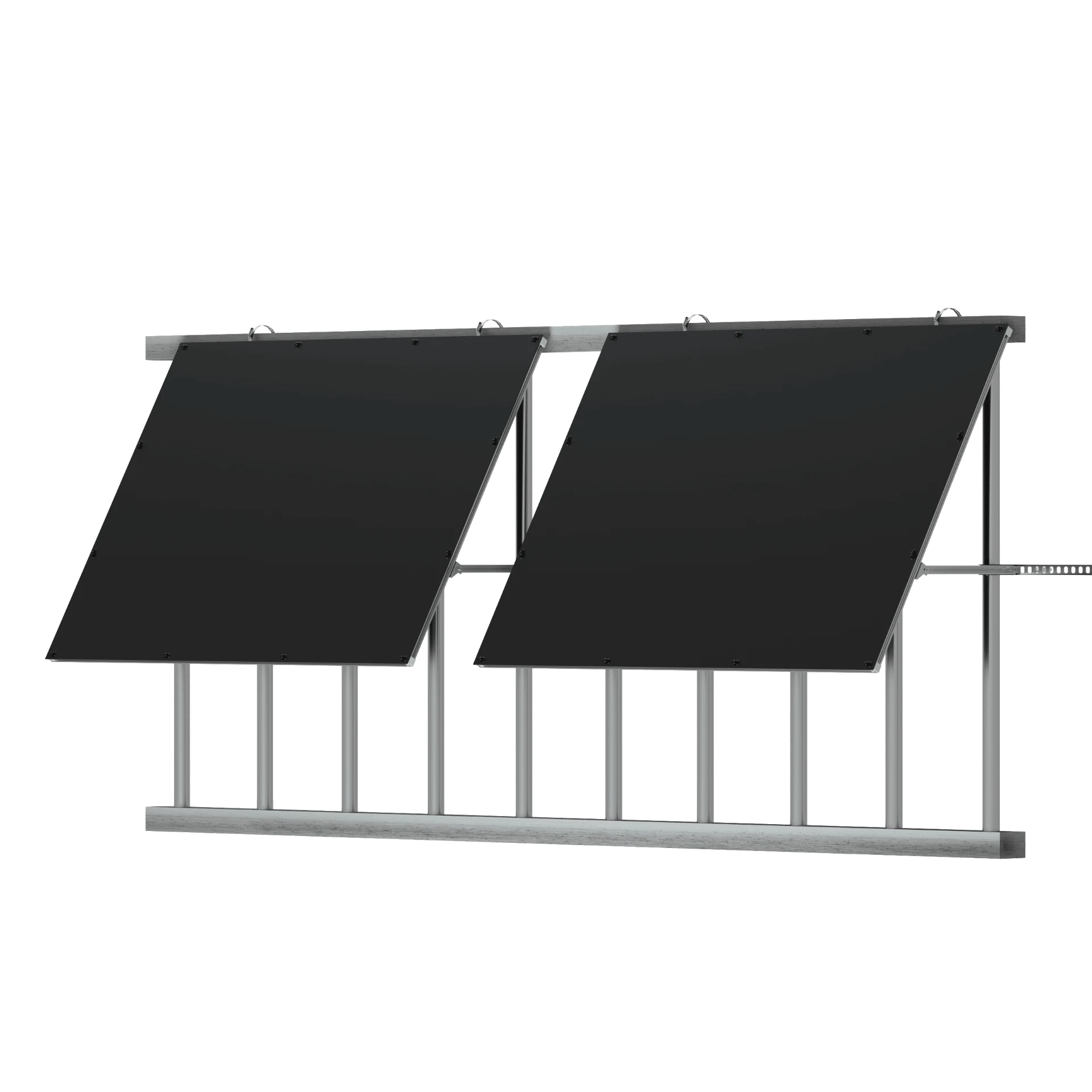

Figure 1: Advanced Microinverter Technology for Distributed PV Systems

Product Overview and Technical Specifications

The GEN3 Microinverter 2-in-1 represents a significant advancement in PV power electronics. As a third-generation microinverter, it is specifically engineered to optimize energy conversion from two high-power solar modules simultaneously, featuring independent Maximum Power Point Tracking (MPPT) for each input. This architectural choice is critical for maximizing power output in challenging conditions, ensuring that the performance of one panel does not negatively impact the other. Its integrated design not only simplifies installation but also enhances system robustness and monitoring capabilities, delivering superior energy production and operational transparency.

Key Technical Parameters

Understanding the core technical specifications of the GEN3 Microinverter 2-in-1 is essential for effective system design and performance evaluation. The following table details the key operational and physical parameters that underscore its high efficiency, durability, and compliance with international standards.

Table 1: GEN3 Microinverter 2-in-1 Key Specifications

| Parameter |

Value / Description |

| Max. Continuous Output Power |

800 VA (e.g., suitable for two 350-500Wp panels) |

| MPPT Voltage Range |

22V – 60V (per input channel) |

| Max. Input Current |

16A per input channel |

| Peak Efficiency |

97.8% |

| CEC Weighted Efficiency |

97.2% |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 (Dust tight and protected against immersion) |

| Communication |

Power Line Communication (PLC) / Wi-Fi |

| Dimensions (L x W x H) |

Approx. 260mm x 190mm x 35mm |

| Weight |

Approx. 2.7 kg |

| Certifications |

UL 1741, IEC 62109, CE, VDE 0126-1-1, AS/NZS 4777.2 |

The IP67 rating ensures the inverter's resilience in challenging environmental conditions, offering complete protection against dust ingress and the effects of temporary immersion in water. This robust design guarantees consistent operation and extended service life, even in environments characterized by high humidity, saline air, or industrial dust, thereby reducing the total cost of ownership over its projected 25-year operational lifespan.

Manufacturing Process and Quality Assurance

The production of the GEN3 Microinverter 2-in-1 is governed by a stringent, multi-stage manufacturing process designed to achieve superior reliability and performance. This process integrates advanced automation, precision engineering, and rigorous testing protocols to ensure every unit meets the highest industry standards.

Detailed Process Flow:

-

Material Procurement and Incoming Quality Control (IQC): The process begins with sourcing high-quality raw materials and components, including advanced gallium nitride (GaN) or silicon carbide (SiC) semiconductors for enhanced efficiency, and durable aluminum alloys for the enclosure. All incoming materials undergo a comprehensive IQC, involving detailed chemical analysis, mechanical strength testing, and electrical parameter verification to eliminate potential defects early. Adherence to ISO 9001 standards ensures robust supply chain management.

-

Automated Printed Circuit Board (PCB) Assembly: State-of-the-art Surface Mount Technology (SMT) lines are utilized for precise placement of electronic components onto multi-layer PCBs. This stage is fully automated, including robotic soldering and Automated Optical Inspection (AOI) systems that detect microscopic defects, ensuring flawless circuit connectivity and signal integrity.

-

Housing Fabrication and Thermal Management: The robust inverter housing is typically produced using precision die-casting of high-grade aluminum alloy, followed by CNC machining to achieve exact tolerances for component fitting and thermal contact. An integrated, finned heat sink design ensures optimal passive thermal dissipation, crucial for maintaining component longevity and efficiency without relying on active cooling fans. The enclosure material is selected for its high corrosion resistance, beneficial for target industries like petrochemicals and metallurgy.

-

Module Integration and Encapsulation: The assembled PCBs and power electronics modules are carefully integrated into the cast aluminum housing. Critical components are then encapsulated with a thermally conductive, UV-resistant potting compound, providing superior protection against moisture, vibration, and thermal stress. The final enclosure is hermetically sealed to achieve its IP67 rating, making it impervious to water and dust—a vital advantage for water supply & drainage facilities or environments exposed to harsh weather.

-

Comprehensive Functional Testing: Each unit undergoes a battery of functional tests, including MPPT accuracy validation across various irradiance and temperature conditions, grid synchronization and anti-islanding tests (conforming to IEEE 1547 and VDE AR 4105), peak efficiency measurements, and power quality analysis. All parameters are meticulously calibrated to ensure optimal performance and energy saving.

-

Accelerated Life and Environmental Stress Testing: Products are subjected to rigorous environmental tests compliant with IEC 62109 and ANSI standards. These include prolonged high-temperature operation, humidity cycling, thermal shock, and salt fog corrosion tests (critical for coastal installations). Vibration testing simulates transport and long-term operational stress. These tests confirm a service life exceeding 25 years under severe conditions.

-

Final Quality Assurance and Packaging: A final visual inspection confirms aesthetic and structural integrity. Each GEN3 Microinverter 2-in-1 is assigned a unique serial number for full traceability. Products are then securely packaged to prevent damage during transit, ensuring they arrive in pristine condition, ready for deployment.

This meticulous manufacturing and testing regimen ensures that the GEN3 Microinverter 2-in-1 delivers unparalleled reliability and performance, making it highly advantageous for energy-saving initiatives and ensuring exceptional corrosion resistance in demanding industrial and environmental contexts.

Application Scenarios and Technical Advantages

The robust design and intelligent features of the GEN3 Microinverter 2-in-1 make it exceptionally versatile, suitable for a wide array of distributed solar applications. Its inherent technical advantages translate into tangible benefits for project developers and end-users alike.

Typical Application Scenarios:

- Residential Rooftop Systems: Maximally efficient for complex residential rooflines often characterized by varying panel orientations, multiple small arrays, and intermittent shading from chimneys, trees, or dormers. The module-level optimization ensures that the system delivers its highest possible energy yield regardless of individual panel performance.

- Commercial and Industrial (C&I) Rooftop PV: Ideal for larger installations on commercial buildings where robust performance, ease of scalability, and comprehensive monitoring are critical. The 2-in-1 architecture reduces the number of units and AC trunk cables required, streamlining installation and lowering BOS costs for extensive arrays.

- Building-Integrated Photovoltaics (BIPV): Facilitates aesthetic and functional integration of solar panels into building envelopes, such as facades or awnings. The compact size and distributed architecture provide flexibility in design and improved safety for occupants by eliminating high DC voltages.

- Agricultural and Remote Installations: Its IP67 rating and wide operating temperature range ensure reliable operation in challenging rural or remote environments, including agricultural facilities, water pumping stations, or telecommunication relays, where durability and minimal maintenance are paramount.

Key Technical Advantages:

- Superior Energy Harvest & Energy Saving: Each of the two PV modules connected to a GEN3 Microinverter 2-in-1 has its own MPPT. This allows each panel to operate at its peak power point independently, yielding up to 25% more energy compared to string inverters, especially in scenarios with partial shading or uneven panel performance.

- Enhanced Safety Protocols: By converting DC power to AC at the module level, the system operates at low DC voltages (below 60V). This eliminates the high DC voltage hazards associated with string inverters, significantly reducing the risk of arc faults and electrical fires. Integrated rapid shutdown functionality complies with the latest safety codes, ensuring immediate system deactivation in emergencies.

- Exceptional Reliability and Corrosion Resistance: The robust IP67-rated enclosure, constructed from corrosion-resistant materials and featuring a fanless design, provides unparalleled protection against environmental degradation. This design ensures optimal thermal management and a prolonged operational life (25+ years), even in highly corrosive atmospheres such as coastal areas, or industrial settings like petrochemical plants or metallurgy operations where airborne particulates and chemicals are present.

- Simplified Installation and Modularity: The 2-in-1 design means fewer physical units to mount and fewer AC cable connections compared to single-panel microinverters. This modularity reduces installation complexity, labor time, and overall BOS costs, making system expansion or reconfiguration straightforward and cost-effective.

- Granular Monitoring and Diagnostics: Module-level performance monitoring provides precise, real-time data for each panel pair. This enables quick identification of underperforming modules, facilitates proactive maintenance, and minimizes system downtime, ensuring maximum operational efficiency and peace of mind for facility managers.

Figure 2: Modular and Resilient Microinverter for Diverse Applications

Vendor Comparison and Competitive Edge

In the highly competitive solar inverter market, the distinguishing features of the GEN3 Microinverter 2-in-1 provide a clear competitive advantage. Our design philosophy centers on maximizing energy yield, ensuring longevity, and simplifying deployment for our B2B partners. Below is a comparative overview highlighting how TSUN-ESS's offering stands against typical market alternatives.

Table 2: Microinverter Vendor Comparison

| Feature/Parameter |

GEN3 Microinverter 2-in-1 (TSUN-ESS) |

Competitor A (Single Panel Microinverter) |

Competitor B (Central/String Inverter) |

| Modules per Inverter |

2 (with independent MPPT) |

1 |

6 to 20+ (shared MPPT) |

| Max. Output Power (AC) |

800 VA |

300-400 VA |

3 kW - 100+ kW |

| MPPT Granularity |

Module-level (2 MPPTs per unit) |

Module-level (1 MPPT per unit) |

String-level (1-4 MPPTs per unit) |

| Peak Efficiency |

97.8% |

97.0-97.5% |

98.0-99.0% (at ideal conditions) |

| Installation Complexity |

Low-Moderate (fewer units than single-panel microinverters) |

Moderate-High (more units, more AC connections) |

Low for inverter, high for DC wiring |

| BOS Cost Impact |

Significant reduction (hardware, labor) |

Moderate (higher unit count) |

Lower inverter cost, higher DC wiring cost & complexity |

| Environmental Protection |

IP67 |

IP67 / IP66 |

IP65 / IP66 (often indoor-rated models) |

| Warranty Duration |

25 Years |

10-25 Years |

5-12 Years |

The GEN3 Microinverter 2-in-1 differentiates itself by offering the granular optimization of traditional microinverters while significantly reducing material and labor costs through its dual-panel design. This results in a superior energy yield per unit cost, simpler installation, and enhanced system resilience compared to both single-panel microinverters and conventional string inverters. The longer warranty and robust IP67 rating further underscore its value proposition for long-term, high-performance solar assets.

Customized Solutions and Integration

At TSUN-ESS, we understand that B2B solar projects often entail specific, nuanced requirements that go beyond standard product offerings. Leveraging our deep technical expertise and engineering capabilities, we provide comprehensive support for customized solutions built around the GEN3 Microinverter 2-in-1. Our approach involves close collaboration with system integrators, EPC firms, and project developers to ensure seamless integration and optimized performance for unique deployments.

Customization services can include adapting firmware for specific grid code compliance in different regions, developing bespoke mounting hardware for non-standard roof types or ground mounts, and integrating with advanced energy management systems via flexible API interfaces. We offer detailed system design and layout consultation, energy yield forecasting using sophisticated simulation tools, and financial impact analysis to demonstrate the long-term value of tailored solutions. Our goal is to ensure that every project leveraging the GEN3 Microinverter 2-in-1 is perfectly aligned with operational goals and maximizes return on investment.

Application Case Studies

Case Study 1: Large-Scale Commercial Rooftop in a Humid Tropical Climate

A leading logistics company in Southeast Asia sought to power its primary distribution center with a 1.2 MW rooftop solar installation. The tropical climate, characterized by high humidity, intense UV radiation, and frequent heavy rainfall, demanded exceptional product durability and corrosion resistance. Deploying approximately 1,500 units of the GEN3 Microinverter 2-in-1 provided a robust solution. The microinverters' IP67 rating and advanced thermal management system ensured consistent operation despite ambient temperatures often exceeding 35°C and high moisture content. Granular monitoring revealed a 6% increase in annual energy yield compared to initial string inverter projections, primarily due to the effective mitigation of partial shading from roof-mounted equipment and frequent cloud cover. The client reported significant operational cost savings and appreciation for the system's resilience against the challenging climate.

Case Study 2: Municipal Water Treatment Plant with Complex Grid Requirements

A municipal water treatment facility required a 400 kW solar PV system to offset its substantial energy consumption. The project site presented unique challenges, including strict local grid interconnection codes, potential for electromagnetic interference from heavy machinery, and a requirement for enhanced safety due to the presence of hazardous chemicals. The integration of 500 units of the GEN3 Microinverter 2-in-1 proved ideal. Its low DC voltage operation inherently minimized electrical hazards, a critical safety advantage in such an industrial setting. Furthermore, the microinverters' rapid shutdown capabilities ensured compliance with stringent safety regulations. TSUN-ESS engineers worked closely with the facility to customize firmware parameters, ensuring perfect adherence to the municipal grid's frequency and voltage stability requirements. The system has consistently delivered high performance, contributing to a significant reduction in the plant's operational expenditures.

Figure 3: Real-world deployment of advanced microinverters in industrial settings.

Commitment to Trustworthiness: FAQ, Logistics, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: How does the 2-in-1 design of the GEN3 Microinverter 2-in-1 reduce installation costs?

- A: By supporting two solar panels with a single microinverter unit, the 2-in-1 design halves the number of physical inverters to install and reduces the total length of AC trunk cabling required compared to single-panel microinverters. This directly translates to significant savings in hardware, labor, and overall Balance of System (BOS) costs.

- Q: What certifications does the GEN3 Microinverter hold?

- A: The GEN3 Microinverter 2-in-1 adheres to a wide range of international safety and performance standards, including UL 1741 (North America), IEC 62109 (International Electrotechnical Commission), CE (European conformity), VDE 0126-1-1 (Germany), and AS/NZS 4777.2 (Australia/New Zealand). These certifications validate its reliability and grid compatibility globally.

- Q: Can the GEN3 Microinverter 2-in-1 operate in off-grid or hybrid configurations?

- A: While primarily designed for grid-tied applications, the GEN3 Microinverter 2-in-1 can be integrated into hybrid systems when paired with appropriate battery storage and charge controllers that manage grid interaction. For completely off-grid scenarios, specific system designs and additional equipment (e.g., dedicated off-grid inverters) would be necessary to ensure stable power delivery.

Lead Time & Fulfillment

TSUN-ESS is committed to efficient logistics and timely order fulfillment for all B2B clients. Our advanced manufacturing facilities and optimized supply chain enable us to manage large-volume orders effectively. Standard lead times for the GEN3 Microinverter 2-in-1 typically range from 4 to 8 weeks, depending on order size, customization requirements, and current global shipping conditions. We offer flexible shipping options, including sea and air freight, to ensure prompt and secure delivery to project sites worldwide. Specific lead times will be provided and confirmed with each quotation and order confirmation, with dedicated project managers overseeing the fulfillment process.

Warranty Commitments

Our confidence in the engineering and manufacturing quality of the GEN3 Microinverter 2-in-1 is reflected in our robust warranty policy. Each unit is backed by an industry-leading 25-year limited product warranty. This extensive coverage protects against defects in materials and workmanship under normal installation, use, and service conditions. This long-term warranty provides peace of mind and assures a low total cost of ownership over the entire lifespan of the solar PV system. Detailed terms and conditions for our warranty are available upon request and provided with every purchase agreement.

Customer Support & After-Sales Service

TSUN-ESS is dedicated to providing exemplary customer support and after-sales service. Our global network of technical support specialists and service partners ensures that assistance is readily available, wherever your projects are located. We offer comprehensive support, including pre-sales technical consultation, system design assistance, installation guidance, and post-installation troubleshooting. Clients can access our expert team via dedicated phone lines, email support, and an online portal for rapid response to inquiries and service requests. We also provide extensive training programs for installers and technicians to ensure optimal deployment and maintenance of our microinverter systems.

Conclusion

The drive for sustainable energy solutions continues to accelerate, with advanced inverter technology at its core. The GEN3 Microinverter 2-in-1 stands as a testament to this evolution, offering an intelligent, efficient, and exceptionally reliable solution for modern distributed photovoltaic systems. Its innovative 2-in-1 architecture provides unparalleled module-level optimization, enhanced safety, simplified installation, and significant reductions in Balance of System costs. Engineered for longevity and performance in diverse and challenging environments, backed by comprehensive certifications and robust customer support, this microinverter is ideally positioned to meet the stringent demands of B2B clients across residential, commercial, and industrial sectors. As the world progresses towards greater energy independence and sustainability, the GEN3 Microinverter 2-in-1 will play a crucial role in maximizing solar energy potential and securing a cleaner, more efficient future.

References

- International Energy Agency (IEA) PVPS. "Trends in Photovoltaic Applications." Annual Report, 2023.

- Solar Energy Industries Association (SEIA). "Solar Industry Research Data & Analysis." 2023-2024.

- National Renewable Energy Laboratory (NREL). "Inverter Reliability and Lifetime Study for PV Systems." Technical Report, NREL/TP-5K00-84517, 2022.

- IEEE Std 1547-2018. "Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces."

- International Electrotechnical Commission (IEC). "IEC 62109-1: Safety of power converters for use in photovoltaic power systems - Part 1: General requirements." 2010.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact Us

Contact Us Monitoring

Monitoring

LEARN MORE

LEARN MORE