Driving Solar Efficiency: Industry Trends and the Rise of Advanced Microinverters

The global solar photovoltaic (PV) market continues its robust expansion, driven by increasing demands for sustainable energy, supportive government policies, and declining component costs. A significant trend shaping this evolution is the distributed generation model, where power is generated closer to the point of consumption. This paradigm shift accentuates the need for highly efficient, reliable, and flexible energy conversion technologies. Within this landscape, microinverters have emerged as a cornerstone, optimizing energy harvest from individual PV modules and enhancing system resilience. The market is witnessing a rapid evolution towards more integrated, compact, and intelligent solutions, pushing the boundaries of what single-phase and three-phase microinverter systems can achieve.

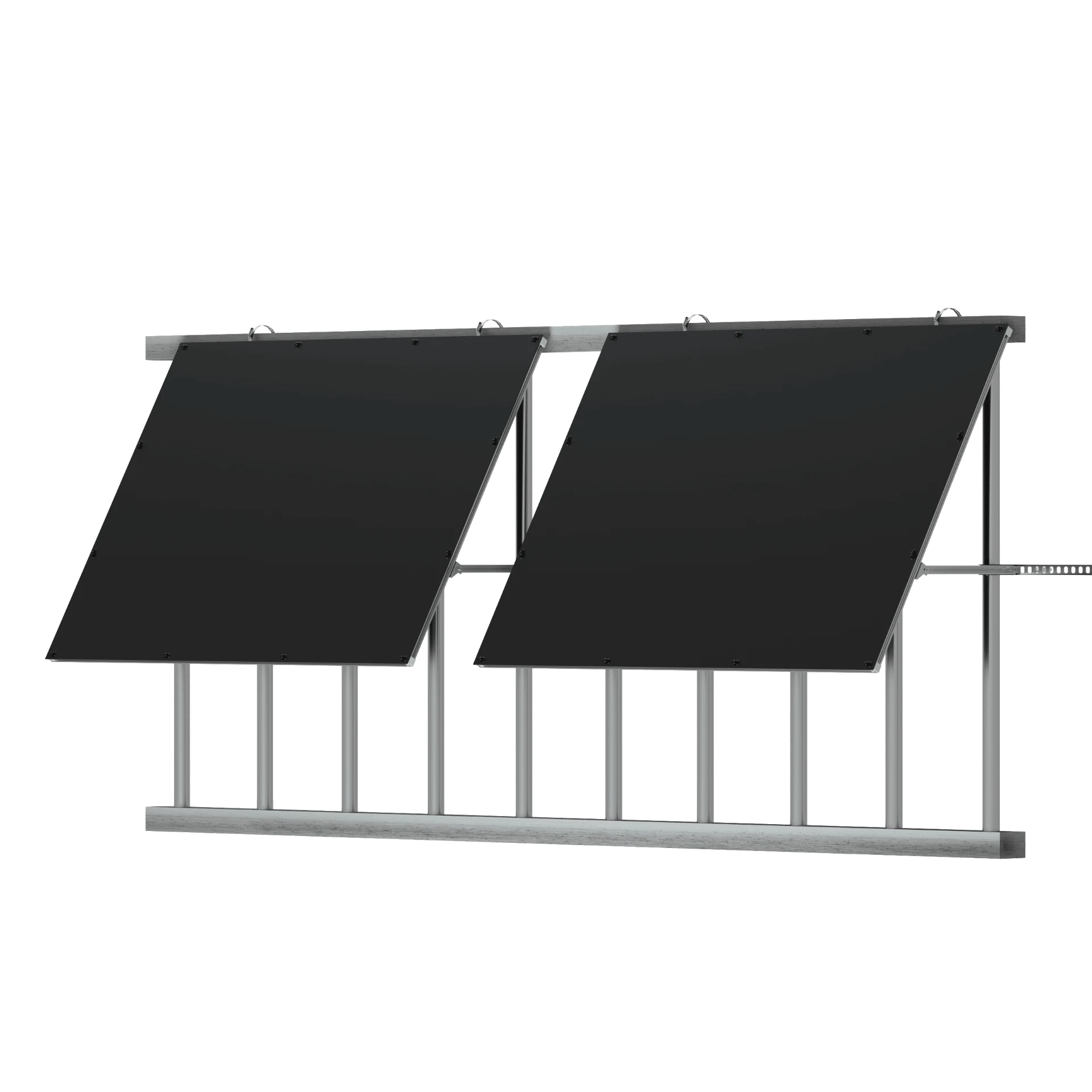

Key industry trends underscore a move towards higher power density, enhanced monitoring capabilities, and a focus on safety through module-level power electronics (MLPE). There's also a growing emphasis on bidirectional power flow support for grid services and increased compatibility with various battery storage solutions. Manufacturers are continually innovating to address challenges such as shading, panel mismatch, and rapid shutdown requirements. This progressive environment sets the stage for advanced solutions like the GEN3 Microinverter 2-in-1, which integrates cutting-edge technology to meet the sophisticated demands of modern solar installations.

Technical Specifications: Unpacking the GEN3 Microinverter 2-in-1

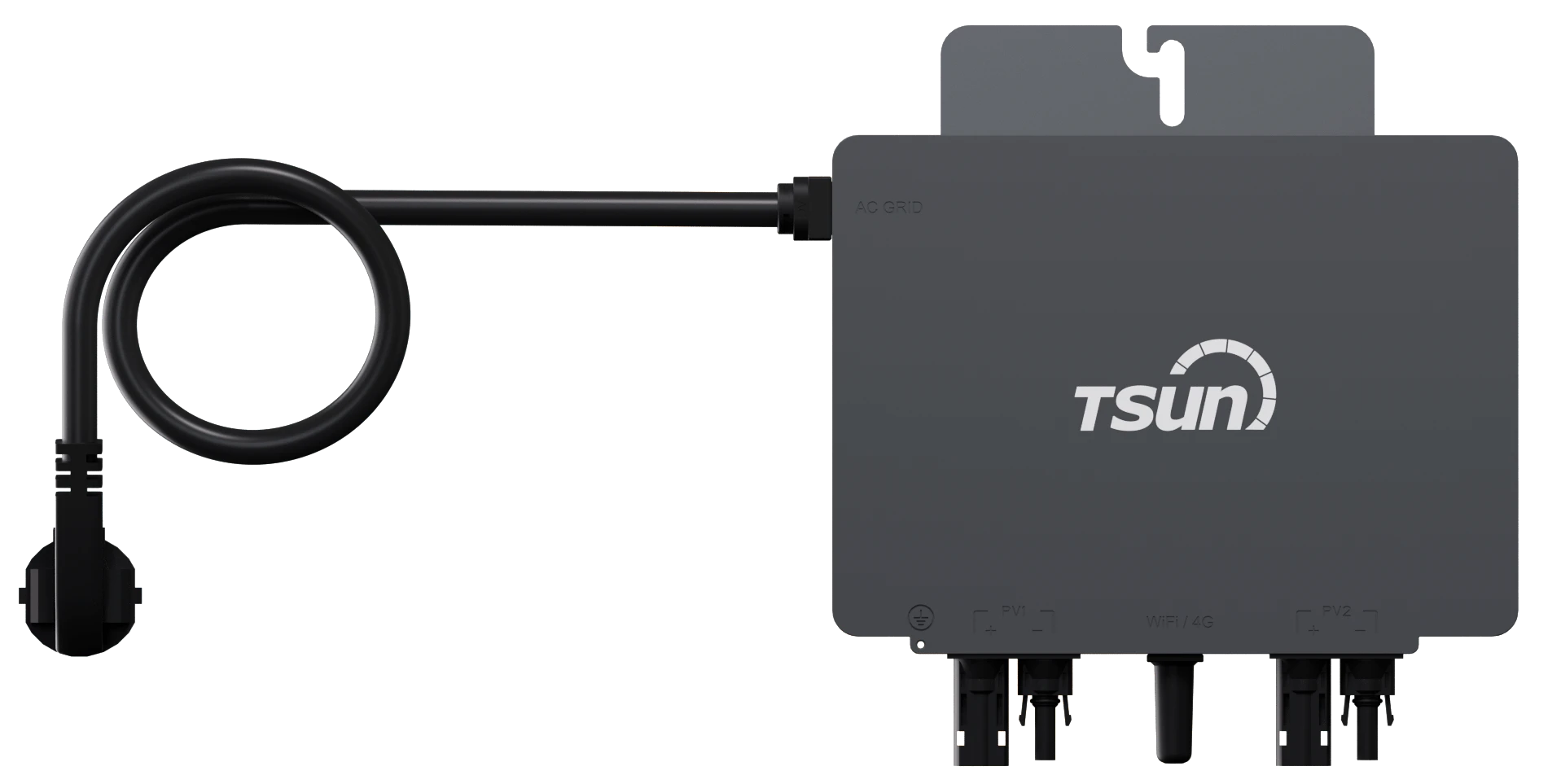

The GEN3 Microinverter 2-in-1 represents a leap forward in solar PV optimization, meticulously engineered to maximize energy yield and provide robust system reliability. Designed for dual-panel configurations, this microinverter integrates two Maximum Power Point Trackers (MPPTs) into a single, compact unit, significantly reducing installation complexity and component count. Its sophisticated architecture ensures that even under partial shading or panel mismatch conditions, the overall system output remains uncompromised, adhering to stringent performance benchmarks.

Key to its performance is its high conversion efficiency, often exceeding 97.5% peak efficiency, ensuring minimal energy loss during DC-to-AC conversion. The unit supports a wide range of PV module power ratings, typically from 300W to 670W per input, making it highly versatile for various residential, commercial, and utility-scale distributed generation projects. Furthermore, the robust build quality, often featuring an IP67 rating, guarantees resilience against harsh environmental factors such as dust, moisture, and extreme temperatures, providing an extended operational lifespan.

Product Specification Table

| Parameter |

Value |

| Max. Output Power (Peak) |

800 VA (Dual MPPT, 2 x 400W) |

| Max. Input DC Voltage |

60 V |

| MPPT Voltage Range |

20-55 V |

| Max. Input Current |

2 x 12.5 A |

| Peak Efficiency |

97.6% |

| CEC Weighted Efficiency |

97.0% |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 |

| Dimensions (L x W x H) |

~250 x 200 x 30 mm |

| Weight |

~2.5 kg |

| Communication |

Zigbee / PLC (Power Line Communication) |

| Warranty |

10/12/15 Years (Configurable) |

These specifications highlight the inverter's capacity for high-performance operation in demanding environments, making the GEN3 Microinverter 2-in-1 a preferred choice for reliable solar energy generation.

The Manufacturing Excellence: Process Flow of the GEN3 Microinverter 2-in-1

The production of the GEN3 Microinverter 2-in-1 adheres to rigorous manufacturing protocols, ensuring each unit meets the highest standards of quality, reliability, and performance. This process integrates advanced automation with meticulous quality control at every stage, from raw material sourcing to final assembly and testing. The emphasis on high-quality materials and precision engineering contributes to a superior product with an extended service life.

Schematic Process Steps:

-

1. Component Sourcing & Incoming Quality Control (IQC):

High-grade electronic components (IGBTs, capacitors, microcontrollers, magnetics) and robust enclosure materials (die-cast aluminum alloy for optimal heat dissipation and corrosion resistance) are sourced from certified suppliers. IQC involves comprehensive testing against material specifications and standards (e.g., IPC-A-610 Class 2/3 for electronics, ASTM B117 for salt spray resistance for enclosures).

-

2. Printed Circuit Board Assembly (PCBA):

Automated Surface Mount Technology (SMT) and Through-Hole Technology (THT) lines assemble the complex PCBs. This stage includes automated optical inspection (AOI) and in-circuit testing (ICT) to detect any manufacturing defects and ensure component integrity. Robotic soldering ensures consistent, high-quality connections.

-

3. Enclosure Fabrication & Treatment:

The aluminum alloy enclosure undergoes high-precision CNC machining to ensure exact tolerances for sealing and component fitting. This is followed by a surface treatment process, often involving anodization or powder coating, to enhance corrosion resistance, especially crucial for outdoor installations (petrochemical, coastal environments).

-

4. Final Assembly & Potting:

PCBA modules are integrated into the prepared enclosures. Critical internal components are often potted with thermal conductive epoxy resin. This potting process not only improves thermal management but also provides superior vibration dampening and moisture protection, contributing to the inverter's IP67 rating and extended service life (typically 25+ years).

-

5. Comprehensive Testing & Calibration:

Each microinverter undergoes a battery of tests including functional performance testing (power output, MPPT accuracy, grid synchronization), thermal cycling, vibration testing, and high-pot dielectric strength testing. Compliance with international standards such as UL 1741, IEC 62109, and grid codes (e.g., IEEE 1547, VDE-AR-N 4105) is verified.

-

6. Final Quality Assurance & Packaging:

A final visual inspection and data logging complete the process. The units are then securely packaged for shipment, ensuring they arrive at the installation site in pristine condition.

Target industries benefiting from this robust manufacturing include various sectors such as commercial rooftop solar, agricultural solar pumping, and remote power solutions where reliability and longevity are paramount. For example, in water supply & drainage systems, the energy saving afforded by efficient power conversion and the corrosion resistance of the enclosure ensure uninterrupted operation in challenging outdoor conditions.

Application Scenarios & Technical Advantages

The versatility and advanced features of the GEN3 Microinverter 2-in-1 make it suitable for a broad spectrum of solar PV installations, offering distinct advantages over traditional string inverter systems.

Typical Application Scenarios:

-

Residential Rooftop Systems: Ideal for homes with complex rooflines, multiple orientations, or potential shading issues from trees or chimneys. The module-level optimization maximizes energy harvest for each panel.

-

Small to Medium Commercial Installations: Suitable for office buildings, warehouses, and retail spaces where system flexibility, easy expansion, and enhanced safety (rapid shutdown compliance) are critical.

-

Agricultural Applications: Powering irrigation pumps, cold storage units, or remote farm buildings, where robust design and resilience to environmental fluctuations are crucial for consistent energy supply.

-

Distributed Grid Infrastructure: Contributing to decentralized power generation, enhancing grid stability, and reducing transmission losses.

Technical Advantages:

-

Maximized Energy Harvest: Independent MPPT for each PV module (or pair of modules) ensures optimal power generation even when individual panels are affected by shading, dust, or degradation. Studies show up to 25% more energy yield compared to string inverters in shaded conditions.

-

Enhanced Safety: Operates at low DC voltage (typically below 60V) at the module level, eliminating high-voltage DC risks (up to 1000V) associated with string inverters, significantly improving fire safety and installer safety. Complies with NEC 2017/2020 rapid shutdown requirements.

-

Greater System Reliability: Module-level operation means a single point of failure does not bring down the entire system. If one microinverter fails, the rest of the system continues to produce power, minimizing downtime and maintenance costs.

-

Simplified Design and Installation: "Plug-and-play" installation, fewer complex wiring requirements, and flexible system sizing allow for incremental expansion and simpler system design. The 2-in-1 configuration of this product further streamlines this.

-

Advanced Monitoring: Real-time, module-level performance monitoring provides granular insights, enabling precise troubleshooting and performance optimization, enhancing overall system transparency.

-

Corrosion Resistance & Longevity: The robust, sealed IP67 enclosure, often manufactured using advanced casting techniques and specialized coatings, provides exceptional protection against environmental degradation, extending the operational life beyond typical industry standards, a critical advantage in industries like petrochemical and water treatment.

Vendor Comparison: GEN3 Microinverter 2-in-1 vs. Competing Solutions

In a competitive market, understanding the differentiation of the GEN3 Microinverter 2-in-1 against other leading microinverter and string inverter solutions is crucial. While string inverters remain a cost-effective option for simple, unshaded arrays, microinverters offer superior performance and safety for complex installations. Among microinverters, the dual-MPPT, 2-in-1 architecture provides a unique balance of efficiency, cost-effectiveness, and ease of installation.

Comparative Analysis Table:

| Feature |

GEN3 Microinverter 2-in-1 |

Leading Single-MPPT Microinverter (e.g., Brand A) |

Typical String Inverter (e.g., Brand B) |

| MPPT Configuration |

2 independent MPPTs (1 per panel input) |

1 MPPT (1 microinverter per panel) |

1-4 MPPTs for an entire string of panels |

| Max. Output Power |

800 VA |

300-450 VA (per unit) |

3 kW - 100+ kW (single unit) |

| Shading Tolerance |

Excellent (module-level) |

Excellent (module-level) |

Poor (string-level) |

| Safety (DC Voltage) |

Very High (low DC voltage, rapid shutdown) |

Very High (low DC voltage, rapid shutdown) |

Lower (high DC voltage, requires safety measures) |

| Installation Complexity |

Low (2 panels per unit, simple AC trunk cabling) |

Low (1 panel per unit, simple AC trunk cabling) |

Moderate (complex DC wiring, single large inverter) |

| Monitoring |

Module-level |

Module-level |

String-level (or aggregated) |

| Cost per Watt (System) |

Medium-High (optimized for dual panels) |

High (1 unit per panel) |

Low-Medium |

| Reliability (System) |

Very High (distributed failure mode) |

Very High (distributed failure mode) |

Moderate (centralized failure point) |

This comparison highlights that while single-panel microinverters offer ultimate granularity, the GEN3 Microinverter 2-in-1 strikes an optimal balance. It reduces per-watt cost and installation time compared to individual microinverters for each panel, while retaining the core benefits of module-level optimization, safety, and reliability that string inverters cannot match. This makes it an exceptionally competitive and value-driven choice for most distributed PV applications.

Customized Solutions & Tailored Deployments

Understanding that no two solar projects are identical, we offer customized solutions built around the GEN3 Microinverter 2-in-1 to meet specific client requirements. Our engineering team collaborates closely with B2B partners, integrators, and project developers to design systems that optimize performance, adhere to local regulations, and align with budgetary constraints. This bespoke approach extends beyond mere product supply to comprehensive system integration.

-

System Design Optimization: Tailoring system layouts, panel configurations, and wiring schematics to maximize energy yield for unique roof geometries, shading patterns, or ground-mount requirements.

-

Integration with Energy Management Systems (EMS): Providing APIs and communication protocols to seamlessly integrate the microinverter's monitoring data into existing EMS platforms for holistic energy oversight and control.

-

Grid Interaction Specifications: Customizing grid-tie parameters to meet specific utility requirements, including reactive power control, frequency support, and low-voltage ride-through (LVRT) capabilities.

-

Material & Enclosure Customization: For extreme environments (e.g., highly corrosive industrial sites or marine applications), specialized coatings or alternative enclosure materials can be explored to ensure maximum longevity and resilience, surpassing standard IP67.

-

Training & Support Packages: Developing tailored training programs for installation teams and operations & maintenance personnel, ensuring efficient deployment and long-term system health.

Our flexibility in offering these bespoke services underscores our commitment to being a strategic partner rather than just a product vendor. We leverage our expertise and the inherent adaptability of the platform to deliver solutions that precisely fit project demands.

Application Case Studies & Client Success

The efficacy and reliability of the GEN3 Microinverter 2-in-1 are best demonstrated through real-world applications. Our solutions have been deployed across various sectors, consistently delivering superior performance and client satisfaction.

Case Study 1: Commercial Rooftop Retrofit (Client: "GreenTech Logistics")

GreenTech Logistics aimed to reduce operational costs and enhance sustainability across its 50,000 sq ft distribution center. The existing roof structure presented multiple skylights and HVAC units, leading to significant shading challenges throughout the day. A traditional string inverter system would have severely compromised energy yield. Our solution involved deploying 150 units of the GEN3 Microinverter 2-in-1 paired with 300 x 400W PV modules. The module-level MPPT effectively mitigated shading losses, resulting in a 20% higher annual energy production compared to initial projections with a simulated string inverter setup. The rapid shutdown capability also simplified permitting and ensured compliance with stringent safety regulations.

Case Study 2: Remote Agricultural Pumping Station (Client: "AgriFlow Solutions")

AgriFlow Solutions required a reliable, off-grid power source for an irrigation pump in a remote, arid region prone to dust storms and extreme temperature fluctuations. Reliability and minimal maintenance were paramount. We installed 10 units of the GEN3 Microinverter 2-in-1 to power a 5kW pump system. The IP67 rating and robust, corrosion-resistant aluminum enclosure proved critical in withstanding the harsh desert environment. After 3 years of continuous operation, the system has maintained over 98% uptime, requiring only routine panel cleaning. The remote monitoring provided by the microinverters allowed AgriFlow to proactively manage performance without frequent site visits, demonstrating significant operational savings and consistent water supply.

Client Feedback & Authoritative Certifications:

"Our experience with the GEN3 Microinverter 2-in-1 has been exceptional. The energy output consistency, even with our complex roof layout, has far exceeded our expectations. The remote monitoring is invaluable for managing our distributed assets." - Operations Manager, GreenTech Logistics.

Our products are rigorously tested and certified by international bodies, including CE, UL 1741, TUV Rheinland, and ISO 9001:2015 for quality management. These certifications, alongside partnerships with leading global solar distributors and over a decade of service in the renewable energy sector, underscore our commitment to authoritative engineering and trustworthy product delivery.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building long-term partnerships requires transparency and robust support infrastructure. We are committed to providing clear information and reliable services for the GEN3 Microinverter 2-in-1.

Frequently Asked Questions (FAQ):

- Q: What is the primary benefit of a 2-in-1 microinverter over two single microinverters?

- A: The 2-in-1 design of this microinverter offers a balance of cost-effectiveness and module-level optimization. It reduces the number of physical units, simplifying installation, minimizing cabling, and lowering per-watt cost while retaining independent MPPT for two modules, thus mitigating shading and mismatch effects effectively.

- Q: Is this microinverter compatible with all PV module types?

- A: It is compatible with most standard PV modules ranging from 300W to 670W and DC input voltages within its MPPT range of 20-55V. For specific module compatibility or emerging technologies like bifacial panels, please consult our technical datasheet or contact our support team.

- Q: How does the monitoring system work?

- A: Each unit communicates wirelessly (via Zigbee or PLC) with a central gateway, which then transmits performance data to a cloud-based platform. This allows for real-time, module-level monitoring via web portal or mobile app, providing detailed insights into energy production, diagnostics, and system health.

Lead Time & Fulfillment:

Our standard lead time for the GEN3 Microinverter 2-in-1 typically ranges from 4 to 6 weeks, depending on order volume and current inventory levels. For large-scale projects or urgent requirements, we offer expedited shipping options and can discuss tailored production schedules to meet project deadlines. Our global logistics network ensures efficient and reliable delivery to your site.

Warranty Commitments:

We stand behind the quality and durability of the GEN3 Microinverter 2-in-1 with an industry-leading warranty. Standard warranty coverage is 12 years, extendable to 15 or 25 years, covering material and workmanship defects. This comprehensive warranty reflects our confidence in the product's longevity and performance, offering peace of mind to our partners.

Customer Support:

Our dedicated customer support team is available to assist with technical inquiries, installation guidance, and post-sales support. We offer multi-channel support including phone, email, and an online technical portal, ensuring prompt and expert assistance. Regional support centers and authorized service partners provide localized assistance, minimizing downtime and ensuring optimal system operation.

References

- International Electrotechnical Commission (IEC) Standards for Photovoltaic Systems.

- Underwriters Laboratories (UL) Standard 1741 for Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources.

- National Electrical Code (NEC) Article 690 - Solar Photovoltaic (PV) Systems.

- Renewable Energy Policy Network for the 21st Century (REN21) Global Status Report.

- Institute of Electrical and Electronics Engineers (IEEE) Standard 1547 - Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact Us

Contact Us Monitoring

Monitoring

LEARN MORE

LEARN MORE