Industry Trends and the Evolution of Solar PV Systems

The global solar photovoltaic (PV) market continues its robust expansion, driven by increasing energy demands, decarbonization targets, and significant technological advancements. A key trend shaping this landscape is the shift towards distributed energy generation, enhancing grid resilience and enabling greater energy independence. Within this paradigm, the role of inverter technology has become paramount, moving beyond simple DC-to-AC conversion to incorporate intelligent grid management, enhanced safety features, and superior energy harvest optimization. Traditional string inverters, while widely used, present limitations in terms of shading susceptibility, system design flexibility, and module-level monitoring. This has paved the way for the increasing adoption of microinverters, which address these challenges by operating at the individual PV module level.

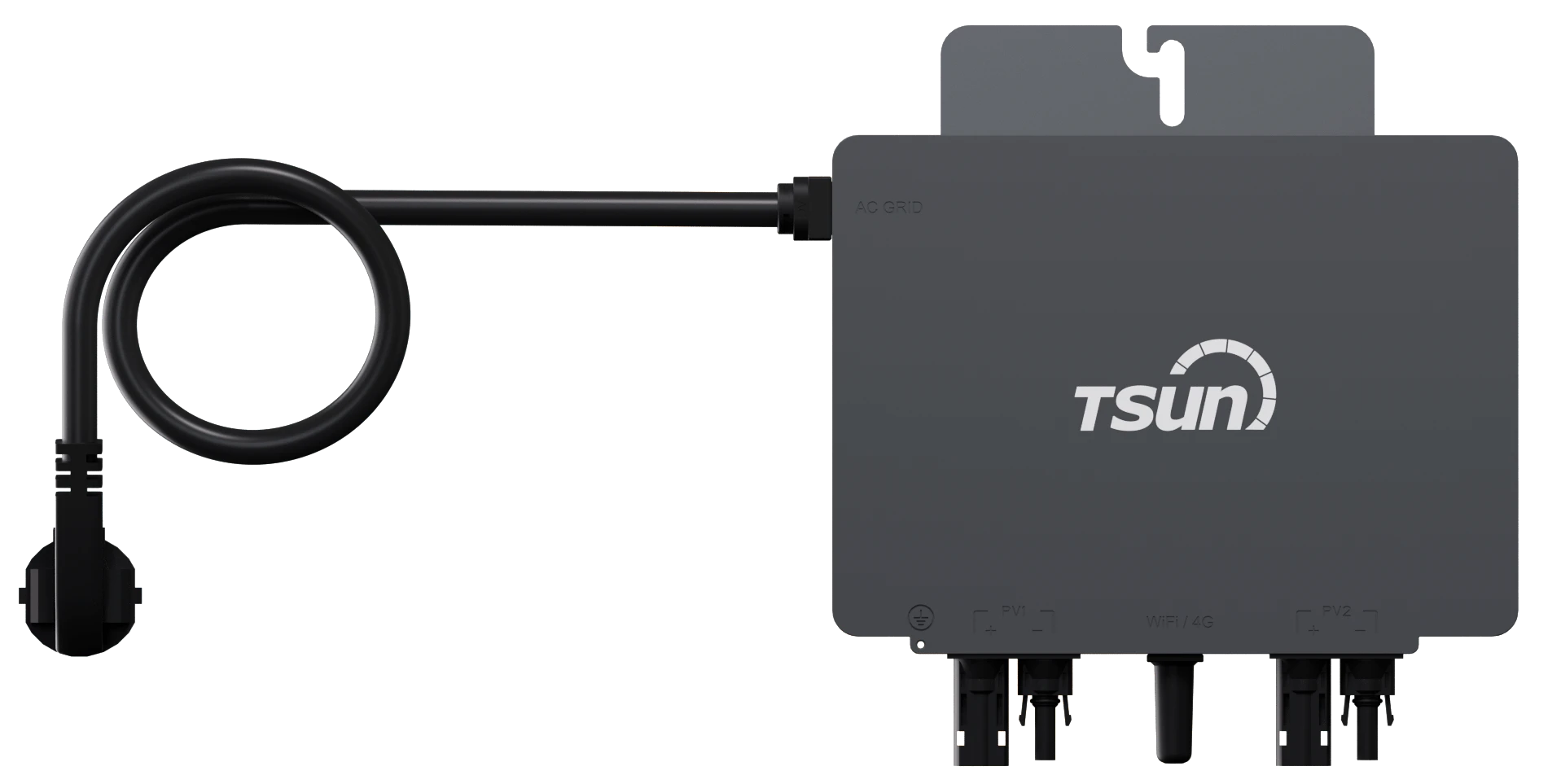

The demand for more integrated, efficient, and robust power electronics is escalating. Industry projections indicate a compound annual growth rate (CAGR) for microinverters exceeding 15% through 2030, reflecting a clear preference for granular control and reliability in both residential and commercial solar installations. Furthermore, the integration of multiple functionalities into a single device – such as rapid shutdown, reactive power compensation, and advanced communication protocols – is becoming a standard expectation. This convergence of features simplifies installation, reduces balance-of-system (BOS) costs, and offers unparalleled system performance. It is in this dynamic environment that advanced solutions like the GEN3 Microinverter 6-in-1 emerge as pivotal technologies, setting new benchmarks for efficiency, flexibility, and reliability in modern solar energy systems.

Beyond mere efficiency, the market is increasingly valuing smart grid functionalities, predictive maintenance capabilities, and highly durable designs capable of withstanding diverse environmental conditions. This emphasis is particularly strong in B2B applications, where long-term operational stability and minimal downtime directly impact profitability and return on investment.

Technical Deep Dive: The Power of GEN3 Microinverter 6-in-1

The GEN3 Microinverter 6-in-1 represents a significant leap forward in microinverter technology, designed to maximize energy harvest and simplify system deployment for multi-module PV arrays. Unlike conventional microinverters that typically connect to one or two modules, this advanced unit integrates the power conversion for up to six individual PV modules. This innovative architecture not only dramatically reduces the number of inverters required for a given system size but also streamlines cabling and installation complexity, leading to substantial savings in labor and materials.

At its core, the GEN3 Microinverter 6-in-1 leverages multiple Maximum Power Point Tracking (MPPT) channels, ensuring that each connected PV module operates at its optimal power point independently. This granular MPPT capability is crucial for mitigating power losses caused by shading, module mismatch, or degradation over time. For instance, if one module is partially shaded, only that module's output is affected, while the other five continue to produce power at their maximum potential. This contrasts sharply with string inverters, where the performance of the entire string can be severely compromised by the weakest link.

The "6-in-1" designation is not merely about module count; it signifies a comprehensive integration of functionalities: DC-to-AC conversion, multiple MPPT channels, module-level monitoring, rapid shutdown compliance, reactive power control, and advanced communication capabilities. This holistic approach ensures not only high energy yield but also enhanced system safety and intelligent grid interaction, making it suitable for modern grid requirements. The robust design includes galvanic isolation, providing an additional layer of safety and protecting against ground faults, a critical feature for high-reliability industrial and commercial installations.

The unit’s sophisticated digital signal processing (DSP) algorithms enable precise control over grid interaction, offering features such as adjustable power factor, frequency regulation, and voltage support. These grid-forming and grid-following capabilities are increasingly vital for integrating large-scale distributed PV into smart grids without compromising stability or reliability.

Core Technical Specifications

Understanding the precise technical parameters of the GEN3 Microinverter 6-in-1 is crucial for system integrators and engineers. The following table details key specifications, highlighting its high performance and robust design, engineered for maximum energy yield and long-term reliability.

GEN3 Microinverter 6-in-1 Key Specifications

| Parameter |

Value / Description |

| Maximum DC Input Power (per MPPT) |

500Wp |

| MPPT Voltage Range |

25V - 60V |

| Maximum DC Input Voltage |

70V |

| Nominal AC Output Power |

2000W (230V) / 2400W (230V) |

| Peak AC Output Power |

2100W (230V) / 2500W (230V) for 30s |

| Nominal AC Voltage Range |

180-270V (Adjustable per region) |

| Nominal AC Frequency |

50Hz / 60Hz (Auto-sensing) |

| CEC Weighted Efficiency |

97.5% |

| Peak Efficiency |

98.0% |

| Nighttime Power Consumption |

< 50mW |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 |

| Communication |

PLC / Wi-Fi / Zigbee (Optional) |

| Certifications |

VDE-AR-N 4105, EN 50549, AS/NZS 4777, UL 1741, IEC/EN 62109-1/2 |

| Warranty |

Standard 10-Year, extendable to 25 Years |

These specifications underscore the unit's capability to deliver high efficiency across a broad operational range, coupled with robust protection against environmental factors. The high IP67 rating ensures resilience against dust ingress and water immersion, making it suitable for demanding outdoor installations.

Manufacturing Process and Quality Assurance

The production of the GEN3 Microinverter 6-in-1 adheres to stringent manufacturing protocols to ensure superior quality and long-term reliability. The process integrates advanced automation with meticulous human oversight, complying with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

Process Flow:

1. Component Sourcing & Incoming Inspection

Selection of high-grade, durable electronic components (IGBTs, capacitors, MCUs) from certified suppliers. Rigorous quality control checks based on ANSI/ASQ Z1.4 sampling plans to verify specifications and material integrity. Emphasis on automotive-grade components for extended service life.

→

2. Automated PCB Assembly (SMT & THT)

Precision Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly on multi-layer PCBs using robotic systems. Automated Optical Inspection (AOI) and X-ray inspection for solder joint integrity and component placement accuracy.

→

3. Functional & Burn-in Testing

Each PCB undergoes comprehensive functional testing to verify electrical parameters. Full-unit burn-in testing under simulated load and thermal cycling conditions for extended periods to expose potential early-life failures (infant mortality).

→

4. Enclosure Assembly & Potting

Precision assembly of the robust, corrosion-resistant aluminum alloy enclosure (die-casting). Application of a thermal potting compound to encapsulate critical electronic components, enhancing thermal management, vibration resistance, and moisture protection to achieve the IP67 rating.

→

5. Final Performance & Environmental Testing

Comprehensive final testing, including full power load tests, grid compliance verification (e.g., anti-islanding, power quality per EN 50549), and environmental stress screening (ESS) for temperature and humidity cycling. This ensures each GEN3 Microinverter 6-in-1 meets all design and regulatory standards.

→

6. Packaging & Shipment

Units are packaged according to international shipping standards, protecting them from physical damage and environmental factors during transit. Traceability data is recorded for each unit.

The use of a robust aluminum alloy casing, typically formed via high-precision die-casting, provides inherent corrosion resistance, crucial for deployment in harsh industrial environments such as coastal areas or facilities near petrochemical plants. The service life of the GEN3 Microinverter 6-in-1 is conservatively estimated at 25 years, aligning with or exceeding the lifespan of most PV modules, due to meticulous component selection, advanced thermal management, and comprehensive environmental sealing.

This commitment to quality ensures not only functional performance but also longevity and resilience, offering significant advantages in total cost of ownership (TCO) for B2B applications.

Application Scenarios and Target Industries

The versatility and robust design of the GEN3 Microinverter 6-in-1 make it ideally suited for a broad spectrum of applications, particularly within the B2B sector where reliability, efficiency, and adaptability are paramount. Its multi-module architecture simplifies large-scale deployments while retaining the benefits of module-level power electronics.

Target Industries:

- Industrial & Manufacturing Facilities: Large rooftops with complex geometries, varied shading patterns from HVAC units or skylights, and high energy demands benefit significantly from the microinverter's granular MPPT and ease of scalability. Energy saving is directly measurable through optimized power generation, contributing to reduced operational costs.

- Commercial Buildings (Offices, Retail Centers): Aesthetic integration, safety (rapid shutdown), and flexible array design are crucial. The GEN3 Microinverter 6-in-1 allows for mixed module types, orientations, and slopes, optimizing solar gain on irregular roof spaces.

- Agricultural Sector: Farms and agricultural processing plants often have extensive roof areas on barns and storage facilities. The system's resilience to dust and varying temperatures, combined with corrosion resistance, makes it a durable choice for these environments.

- Utilities & Energy Infrastructure (e.g., Substations, Pump Stations): For distributed generation projects, critical infrastructure often requires extremely high reliability and quick fault isolation. The individual module management minimizes system downtime and simplifies maintenance.

- Petrochemical and Metallurgy (Specific Use Cases): While direct exposure to highly corrosive agents is limited for PV, microinverters can be integrated into solar installations on buildings within these complexes. The corrosion-resistant aluminum casing and IP67 rating ensure the microinverter’s longevity in areas with elevated atmospheric pollutants or humidity, such as near cooling towers or process exhaust stacks, reducing maintenance in these challenging environments.

- Water Supply & Drainage Facilities: These facilities often operate in remote locations with critical power needs. The robust environmental protection of the GEN3 Microinverter 6-in-1 ensures continuous operation even in humid or potentially submerged (briefly) conditions (IP67), enhancing energy independence and operational continuity.

In all these scenarios, the key advantages lie in maximizing energy harvesting, enhancing system safety through module-level rapid shutdown capabilities compliant with NEC standards, and providing detailed performance monitoring for proactive maintenance. The system's inherent design promotes energy saving by ensuring each module contributes its maximum potential, directly translating to lower electricity bills and faster ROI for businesses.

Technical Advantages and Performance Metrics

The GEN3 Microinverter 6-in-1 stands out due to its unique combination of technical prowess and operational benefits. These advantages translate directly into higher yields, enhanced safety, and greater system longevity for B2B clients.

Key Advantages:

- Superior Energy Harvest: With six independent MPPT channels, each module's output is optimized, completely eliminating the "Christmas light effect" where shading on one module impacts the entire string. This can lead to 15-25% higher energy yield compared to string inverter systems in partially shaded or complex roof environments.

- Enhanced Safety: The microinverter converts DC power to AC at the module level. This eliminates high-voltage DC wiring runs across the roof, significantly reducing fire hazards. Integrated rapid shutdown capabilities automatically de-energize the PV array to a safe voltage level (typically

- Granular Monitoring and Diagnostics: Module-level monitoring provides precise performance data for each PV panel, allowing for quick identification of underperforming modules, fault detection, and proactive maintenance, minimizing downtime and maximizing system uptime.

- Flexible System Design: The modular nature allows for easy expansion of the PV system over time. Furthermore, it supports diverse array orientations, mixed module types, and varying roof pitches, making it ideal for non-uniform commercial rooftops and architectural integrations.

- High Reliability and Durability: Boasting an IP67 enclosure rating and an operational temperature range from -40°C to +65°C, the microinverter is built to withstand extreme environmental conditions, from severe cold to intense heat and moisture. Its passive cooling design (no moving parts like fans) further enhances reliability and reduces maintenance needs.

- Advanced Grid Integration: Features such as reactive power control, frequency support, and voltage regulation allow the GEN3 Microinverter 6-in-1 to contribute actively to grid stability, a crucial requirement for modern grid-tied systems. This often enables higher penetration rates of solar PV on local grids.

- Simplified Installation and Reduced BOS Costs: By consolidating up to six modules into one inverter, the number of devices to install and wire is significantly reduced compared to 1-in-1 or 2-in-1 microinverters, lowering labor costs, AC trunk cable requirements, and overall balance-of-system expenses.

These advantages collectively contribute to a lower Levelized Cost of Energy (LCOE) over the lifespan of the PV system, making the GEN3 Microinverter 6-in-1 an economically attractive and technically superior choice for commercial and industrial solar deployments.

Competitive Landscape and Vendor Comparison

The microinverter market is competitive, with several established players and emerging innovators. While many offer robust single or dual-module microinverters, the GEN3 Microinverter 6-in-1 distinguishes itself through its higher module integration density, balancing granular control with system simplification. Below is a comparison table outlining key differentiators against common market offerings.

Microinverter Comparison: GEN3 Microinverter 6-in-1 vs. Typical Market Offerings

| Feature/Parameter |

GEN3 Microinverter 6-in-1 |

Standard 2-in-1 Microinverter |

String Inverter + Optimizers |

| Modules per Inverter |

Up to 6 |

2 |

Typically 12-20 modules per string (optim. on each) |

| MPPT Channels |

6 Independent |

2 Independent |

Module-level optimization, centralized MPPT at inverter |

| Installation Complexity |

Moderate (Fewer units, simplified AC trunking) |

Higher (More units, more trunking) |

Moderate (Optimizers at module, string inverter on wall) |

| DC Wiring on Roof |

Minimal (Short runs to microinverter) |

Minimal (Short runs to microinverter) |

Extensive (High voltage DC from modules to string inverter) |

| Safety (Rapid Shutdown) |

Integrated, module-level compliance (NEC 2017/2020) |

Integrated, module-level compliance (NEC 2017/2020) |

Module-level compliance via optimizers, requires specific inverter pairing |

| Monitoring Granularity |

Module-level |

Module-level |

Module-level (via optimizers) |

| Shading Performance |

Excellent (Independent MPPT per module) |

Excellent (Independent MPPT per module) |

Excellent (Module-level optimization) |

| Cost Efficiency (BOS) |

High (Fewer inverters, less cabling, labor) |

Moderate |

Moderate to High (Requires both optimizers and inverter) |

This comparison illustrates that while all microinverter and optimizer solutions offer benefits over traditional string inverters, the GEN3 Microinverter 6-in-1 carves a unique niche by combining the high granularity of module-level power electronics with a streamlined installation process, offering a compelling blend of performance, safety, and cost-effectiveness for larger installations.

Customized Solutions

Recognizing that no two commercial or industrial PV installations are identical, we offer tailored solutions leveraging the flexibility of the GEN3 Microinverter 6-in-1. Our engineering team collaborates closely with B2B clients to design systems that precisely meet specific site conditions, energy demands, and budgetary constraints.

- System Sizing and Configuration: We optimize the number and placement of GEN3 Microinverter 6-in-1 units to match the array size, module types, and desired output, ensuring maximum efficiency and cost-effectiveness.

- Grid Integration Strategies: For complex grid requirements, we can configure specific reactive power settings, frequency response curves, and voltage regulation parameters to ensure seamless integration and compliance with local utility regulations.

- Monitoring and Control Customization: While standard monitoring is robust, we can integrate with existing Building Management Systems (BMS) or customize data visualization dashboards to provide specific metrics and alerts relevant to the client's operational needs. This includes API integration for large-scale energy management platforms.

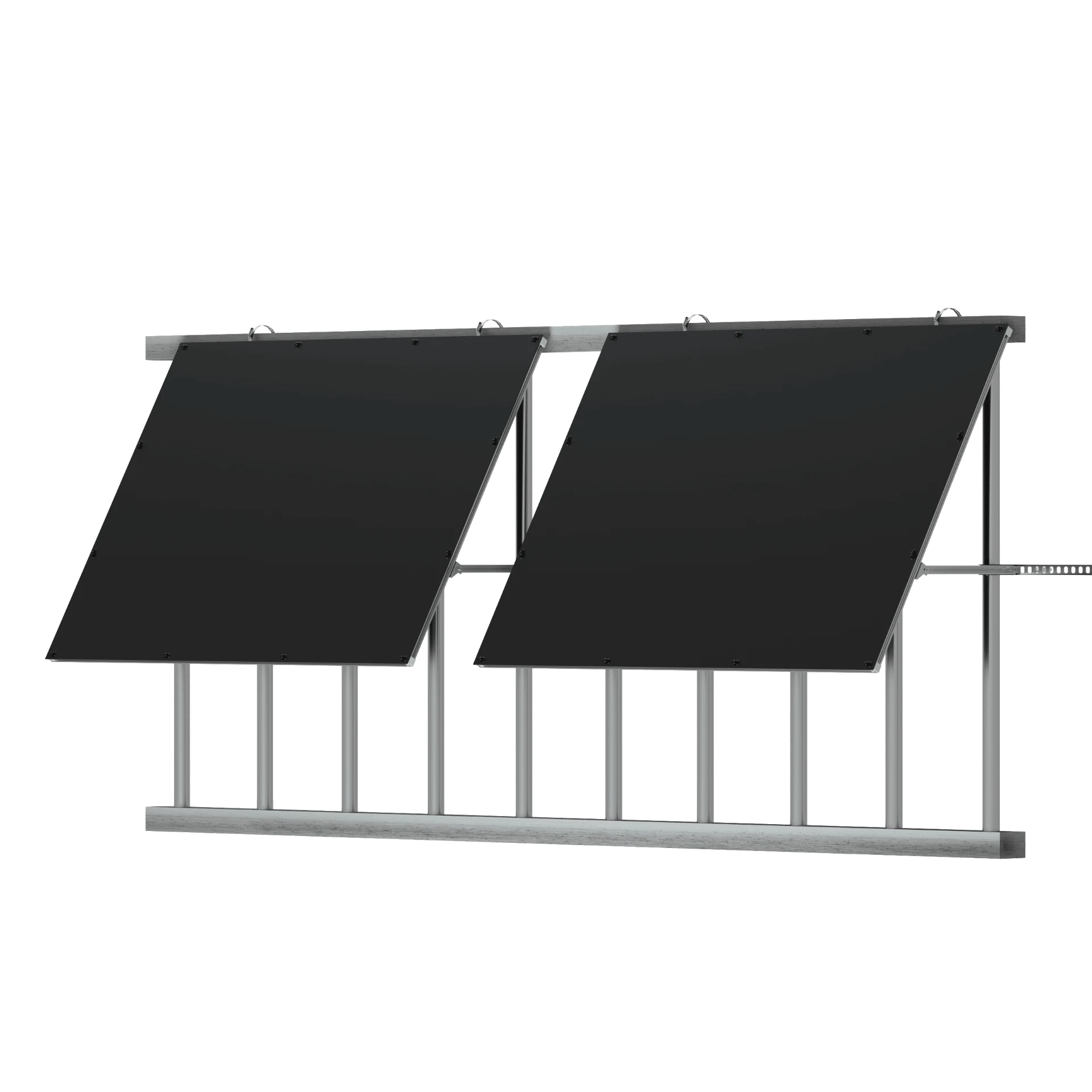

- Mounting and Structural Adaptations: Collaborating with structural engineers, we can assist in designing mounting solutions that accommodate challenging roof structures or ground-mount requirements, ensuring optimal module tilt and orientation while maintaining structural integrity.

- Specialized Environmental Hardening: For deployments in exceptionally harsh environments (e.g., extreme salinity, high chemical exposure), we can recommend specific protective coatings or specialized installation practices to further enhance the longevity and resilience of the microinverter units, building on their inherent IP67 and corrosion-resistant design.

Our approach ensures that every deployment of the GEN3 Microinverter 6-in-1 is a precisely engineered solution, maximizing return on investment and operational reliability for our partners.

Real-World Application Case Studies

The efficacy and reliability of the GEN3 Microinverter 6-in-1 are best demonstrated through its successful deployment in diverse commercial and industrial settings. These case studies highlight the tangible benefits realized by our clients.

Case Study 1: Large Industrial Complex (Manufacturing)

Client: A leading automotive parts manufacturer with a 500,000 sq ft facility in a region prone to significant partial shading from existing infrastructure and frequent cloud cover.

Challenge: Maximize energy production across a complex rooftop with numerous vents, HVAC units, and varying roof orientations, while ensuring robust rapid shutdown compliance for factory safety protocols.

Solution: Installation of a 1.2 MW PV system utilizing the GEN3 Microinverter 6-in-1. The multi-MPPT architecture allowed for flexible module placement and minimized shading losses. The integrated rapid shutdown simplified compliance.

Results: The system achieved a 22% higher annual energy yield compared to initial projections for a string inverter system, primarily due to superior shading mitigation. Maintenance costs were reduced by 15% in the first year due to precise module-level diagnostics. The plant reported significant energy savings, reducing their grid dependency by 35% during peak production hours.

Case Study 2: Commercial Retail Park

Client: A developer managing a new retail park comprising multiple buildings with varied roof designs and tenant energy profiles.

Challenge: Implement a modular, expandable solar solution that could adapt to future tenant changes and offer individual monitoring for each building, all while maintaining aesthetic appeal and high safety standards.

Solution: Deployment of a distributed PV system across the retail park, with each building utilizing GEN3 Microinverter 6-in-1 units. This allowed for independent system sizing per building and segregated energy production monitoring.

Results: The project was completed 20% faster due to simplified wiring and fewer inverter units. Module-level monitoring enabled transparent billing for individual tenants based on their actual solar energy consumption. The integrated safety features provided peace of mind for both the developer and tenants, and the system delivered consistent power, contributing to the park's LEED certification efforts.

Case Study 3: Remote Pumping Station (Water Treatment)

Client: Regional Water Authority operating a critical pumping station in a humid, often rainy coastal environment.

Challenge: Establish a reliable, off-grid or grid-supplementary power source that could withstand corrosive salt air and high humidity, minimizing maintenance requirements in a hard-to-access location.

Solution: A 50kW solar array integrated with battery storage, powered by GEN3 Microinverter 6-in-1 units. The IP67 rating and corrosion-resistant design were key selection criteria.

Results: After two years of operation, the system has demonstrated exceptional reliability with no failures attributed to environmental factors. The facility now operates with 70% renewable energy, drastically reducing diesel generator run-time and associated fuel/maintenance costs. The robust design of the microinverters proved invaluable in maintaining continuous operation in this critical, challenging environment.

Ensuring Trust: Certifications, Warranty, and Support

Our commitment to quality, reliability, and customer satisfaction is foundational. The GEN3 Microinverter 6-in-1 is backed by comprehensive certifications, a robust warranty, and dedicated customer support, ensuring peace of mind for our B2B partners.

Authoritative Certifications:

The GEN3 Microinverter 6-in-1 is certified to meet the highest international safety, performance, and grid-interconnection standards. These include:

- VDE-AR-N 4105 (Germany): Grid connection of generating plants to the low-voltage network.

- EN 50549 (Europe): Requirements for generators to be connected in parallel with the public low-voltage distribution network.

- AS/NZS 4777 (Australia/New Zealand): Grid connection of energy systems via inverters.

- UL 1741 (North America): Inverters, converters, controllers and interconnection system equipment for use with distributed energy resources.

- IEC/EN 62109-1/2 (Global): Safety of power converters for use in photovoltaic power systems.

- ISO 9001 & ISO 14001: Manufacturing processes are certified for quality management and environmental management, respectively.

These certifications validate the product's compliance and performance under diverse regulatory frameworks, making it a globally applicable solution.

Warranty Commitments:

We stand by the exceptional quality and longevity of our products. The GEN3 Microinverter 6-in-1 comes with a standard 10-year product warranty. This warranty can be optionally extended up to 25 years, aligning with the expected lifespan of most high-quality PV modules. Our warranty covers material defects and workmanship, reflecting our confidence in the product's durability and performance.

Lead Time and Fulfillment:

Our streamlined logistics and robust supply chain ensure efficient order processing and timely delivery. Standard lead times for the GEN3 Microinverter 6-in-1 typically range from 2-4 weeks, depending on order volume and destination. For large-scale projects or urgent requirements, we work closely with clients to establish expedited fulfillment schedules. Our global distribution network ensures reliable and cost-effective shipping to key markets.

Customer Support:

Our dedicated technical support team comprises experienced engineers and solar experts, available to assist with system design, installation guidance, troubleshooting, and post-installation support. We offer multi-channel support including phone, email, and an online portal for ticketing and resource access. Our goal is to ensure smooth project execution and maximum uptime for all installations featuring the GEN3 Microinverter 6-in-1.

Partnership with TSUN-ESS means accessing not just cutting-edge technology but also a comprehensive ecosystem of support designed for B2B success.

Frequently Asked Questions (FAQ)

Q: How many PV modules can be connected to one GEN3 Microinverter 6-in-1?

A: The GEN3 Microinverter 6-in-1 is designed to connect up to six individual PV modules, each with its own MPPT. This allows for optimal performance even when modules have varying characteristics or are subject to partial shading.

Q: Is the GEN3 Microinverter 6-in-1 compatible with all types of PV modules?

A: It is compatible with most standard PV modules within its specified DC input voltage and power range. We recommend checking the module's electrical characteristics (Voc, Vmp, Imp, Pmax) against the microinverter's specifications to ensure optimal matching.

Q: What kind of monitoring capabilities does the system offer?

A: The system provides module-level monitoring, allowing users to track the performance of each individual PV panel. Data is accessible via a user-friendly online portal or mobile app, offering insights into energy production, fault detection, and system health.

Q: Does the GEN3 Microinverter 6-in-1 comply with rapid shutdown requirements?

A: Yes, it fully complies with rapid shutdown requirements, such as those mandated by NEC 2017 and 2020. In the event of an emergency or utility power outage, the microinverter rapidly reduces DC voltage to safe levels within the array boundary.

Q: What is the expected lifespan of the product?

A: Designed with high-quality components and robust construction, the GEN3 Microinverter 6-in-1 has an expected operational lifespan of 25 years, matching the typical warranty period of most PV modules.

Conclusion and Future Outlook

The GEN3 Microinverter 6-in-1 stands at the forefront of distributed solar power technology, offering an unparalleled combination of efficiency, safety, flexibility, and cost-effectiveness for commercial and industrial applications. By integrating six MPPT channels into a single, robust unit, it addresses the complexities of modern PV installations, overcoming challenges posed by shading, diverse roof architectures, and stringent safety regulations.

As the global energy transition accelerates, the demand for intelligent, resilient, and high-performance solar solutions will only intensify. The GEN3 Microinverter 6-in-1 is not merely a product; it is a strategic asset for businesses looking to optimize their energy consumption, reduce operational costs, and achieve sustainability goals. Its advanced grid interaction capabilities prepare it for future smart grid requirements, ensuring long-term relevance and value.

With a strong foundation in rigorous manufacturing standards, comprehensive certifications, and dedicated customer support, the GEN3 Microinverter 6-in-1 represents a reliable and forward-thinking investment in the future of solar energy.

References

- International Electrotechnical Commission (IEC) Standards, e.g., IEC 62109-1: Safety of power converters for use in photovoltaic power systems – Part 1: General requirements.

- Institute of Electrical and Electronics Engineers (IEEE) Standards, e.g., IEEE 1547: Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces.

- National Electrical Code (NEC) 2017 & 2020, Article 690: Solar Photovoltaic (PV) Systems, specifically rapid shutdown requirements.

- International Organization for Standardization (ISO) 9001: Quality management systems – Requirements.

- European Standard EN 50549-1: Requirements for generators to be connected in parallel with the public low-voltage distribution network – Part 1: Connection to a LV distribution network – Generators up to Type B.

- U.S. Department of Energy (DOE) SunShot Initiative reports and analyses on PV system costs and performance.

- Solar Energy Industries Association (SEIA) market reports and technical briefs on inverter technology.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE