LEARN DETAILS

LEARN DETAILS

1. Industry Trends and Market Data: The Rise of Hybrid Microinverter

According to Wood Mackenzie, the global microinverter and hybrid inverter market is projected to reach USD 5.6 billion by 2027, at a CAGR of 18.4%. This surge is powered by:

- Transition to decentralized energy systems for both homes and industries

- Integration demand for solar-plus-storage setups

- High microinverter penetration rates in Europe, North America & Asia-Pacific

2. Technical Parameters: Specification & Comparison Table

| Model | Rated Output Power | PV Input Voltage Range | Max Efficiency | AC Output Voltage | Hybrid Mode | MPPT Channels | Operating Temp | Certifications |

|---|---|---|---|---|---|---|---|---|

| Hybrid Microinverter HM-850 | 850 W | 22–60 V | 96.7% | 230 V / 120 V | Solar, Battery | 2 | -40℃ ~ +65℃ | IEC/EN 62109, VDE 4105 |

| Enphase IQ8H | 384 W (per module) | 16–60 V | 97.0% | 230 V / 208 V | Solar, Grid-tied | 1 | -40℃ ~ +60℃ | UL 1741, IEEE 1547 |

| Hoymiles HMS-1000 | 1000 W | 16–60 V | 96.5% | 230 V | Solar | 2 | -40℃ ~ +65℃ | CE, SAA |

| Tigo TS4-A-O | 700 W | 16–72 V | 96.0% | 220 V | Optimizer | 1 | -40℃ ~ +70℃ | IEC, UL |

3. Manufacturing Process: From Design to Delivery

4. Application Scenarios & Technical Benefits

- Petrochemical Industry: Reliable continuous operation in harsh, corrosive, and hazardous locations, due to reinforced potting and Class H insulation.

- Metallurgical Facilities: High thermal resilience (operating up to +65℃), fast grid-matching during voltage fluctuation, individual panel MPPT for max efficiency even in partial shading.

- Commercial & Industrial Buildings: Integrated Hybrid Microinverter with battery backup minimizes downtime and provides peak shaving. Smart monitoring via RS485/Wi-Fi.

- Municipal Water, Wastewater, and Drainage: Anti-surge design, IP67 waterproofing & scheduled maintenance alerts reduce OPEX.

- Residential Rooftops: Power supply to essential loads during outages; plug-and-play installation compatible with various PV module brands.

Technical Edge & Real-World Impact

- Dual-channel independent MPPT ensures module-level optimization, even for mixed irradiation conditions.

- Over 3% higher average annual yield vs. string inverters (based on TÜV Rheinland testing).

- Anti-corrosion grade enclosure (10,000hr salt spray compliant; ISO 9227)

- Vibration tested (IEC 60068-2-6), >25-year service life proven

- Meets rapid shutdown standards (NEC 690.12, VDE-AR-N 4105)

- Instant arc-fault detection, integrated ground-fault interruption

5. Vendor Comparison: Hybrid Microinverter vs. Alternatives

| Vendor | Hybrid Mode | Max Output (W) | MPPT Channels | Efficiency (%) | Certifications | Cloud Monitoring |

|---|---|---|---|---|---|---|

| Tsun | Solar + Battery | 850–2000 | 2 | 96.7 | IEC, VDE | Yes |

| Enphase | Solar + Grid | 384 per module | 1 | 97.0 | UL | Yes |

| Hoymiles | Solar | 1000 | 2 | 96.5 | CE | Optional |

| Sungrow | Hybrid | 6000 (string) | 1 | 97.2 | IEC, VDE | Yes |

6. Customization & Delivery: Tailoring Hybrid Microinverter to Your Project

- Specification Flexibility: Output power (500–2000W), AC voltage (120/230/400V), enclosure coatings (marine-grade anodizing, PTFE coating) can be specified.

- Industry Tailoring: Components can be specified to meet ISO 13849, UL 1741, or harsh site rating (salt-mist, sand, humidity, EMC).

- Branding & Smart Integration: Custom cover branding, communication protocols (RS485, ZigBee, LoRa, Wi-Fi), app/web dashboard.

- Delivery & Support: Typical manufacturing lead time: 3–6 weeks, with module serial traceability. All Hybrid Microinverter products come with a 10–25 year warranty (extendable), 24/7 remote expert support, and multilingual installation guides.

7. Application Cases & Field Performance

- China Petrochemical Facility (2023): Implemented 1.2MW rooftop solar using Hybrid Microinverter, achieving 99.5% uptime through robust anti-surge and IP68-grade protection, reducing grid dependency by 28%.

- German Commercial Bakery (2022): Retrofitted string inverters with Tsun HM-850 microinverters; improved partial-shading energy yield by 7.4% verified by customer’s annual monitoring reports.

- Municipal Wastewater Pump Station, UAE (2023): Operated with zero inverter failures in temperatures up to 57℃. Remote diagnostics enabled

- Green Residential Project, Spain (2024): Pilot of hybrid mode (solar + 4.8kWh LiFePO4 storage), providing seamless backup and lowering peak grid draw by 35%.

8. FAQ: Expert Answers on Hybrid Microinverter Technical Details

A: The enclosure and heat sink are manufactured from die-cast aluminum alloy (typically 6061-T6), offering high strength, excellent heat conductivity (≈ 167 W/mK), and robust corrosion resistance. Some models feature marine-grade anodizing for harsh environments.

A: Modern Hybrid Microinverter units reach up to 97.0% peak CEC efficiency and offer MPPT tracking with accuracy above 99.5% using advanced digital controllers (Texas Instruments C2000, Infineon XMC).

A: Certified per IEC/EN 62109 (safety), ANSI/UL 1741 (North America), VDE-AR-N 4105 (Germany), and IEC 61000-6-1/-2/-3/-4 for EMC compliance. All products also meet RoHS, REACH, and are manufactured in ISO 9001 certified facilities.

A: Designed for a 25-year service life (MTBF >100,000 hours) under standard conditions. Standard warranty is 10 years, with options up to 25 years and on-site replacement within 72 hours in key regions.

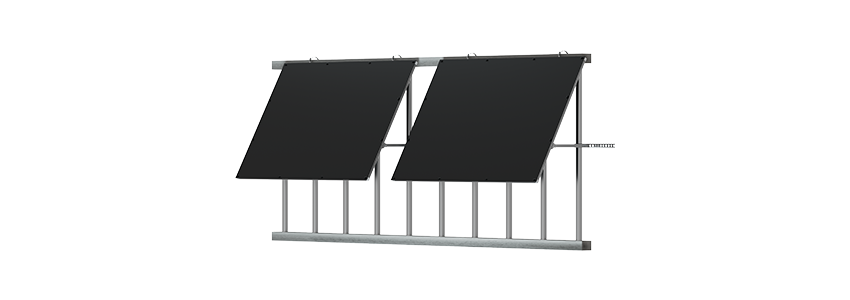

A: Installation is "plug-&-play" using MC4 connectors and pre-terminated AC cables. No special grounding required due to Class II double insulation. String design flexible; supports both portrait and landscape module arrays.

A: Selected models directly support LiFePO4 or NMC batteries (48V/96V), with dynamic charge/discharge management, seamless UPS switching (

A: Integrated monitoring is provided via app/web/cloud, supporting remote diagnosis, OTA updates, and automated alerting on faults or anomalies. Global service network offers technical hotline and onsite support.

9. Delivery Times, Warranty & Customer Support

- Typical Lead Time: 3–6 weeks post-PO for standard units; custom orders may vary based on configuration and test cycles.

- Warranty: 10–25 years, extendable. Full replacement or repair under warranty with tracked logistics.

- Support: 24/7 hotline, remote diagnostics, multilingual documentation, and local field engineers in 18+ countries.

- Spare Parts & Upgrade: Guaranteed availability for at least 15 years after purchase. OTA firmware upgrades ensure compliance with evolving grid codes.

10. References & Authoritative Sources

- Wood Mackenzie & IHS Markit Market Analysis: Hybrid Inverter Market Trends

- TÜV Rheinland Performance Reports: PV/Hybrid Inverter Testing

- Solar Power World, “The rise of hybrid microinverters” SPW: Hybrid Microinverter Article

- PV-Tech Analysis: Global Hybrid Inverter Market Insights

- TSUN Official Product Page: Hybrid Microinverter

“Compared with traditional string or central inverters, Hybrid Microinverter systems demonstrate superior flexibility, yield, and resilience, especially under partial-shade or complex roof scenarios. Their modularity and hybrid functionality address both current and future energy integration needs.”

— Solar PV Forum, April 2024 (Read Discussion)

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE