Understanding the Modern PV Micro Inverter Landscape

The landscape of solar energy generation is rapidly evolving, driven by advancements in power electronics and a growing demand for distributed renewable solutions. At the forefront of this transformation is the pv micro inverter, a technology revolutionizing how photovoltaic (PV) modules convert sunlight into usable electricity. Unlike traditional string inverters, which manage an entire array of panels, microinverters optimize power at the individual module level, offering significant benefits in efficiency, safety, and system resilience.

Current industry trends indicate a strong shift towards modular and intelligent solar solutions. Factors such as increasing rooftop complexity, the need for enhanced fire safety, and the desire for granular system monitoring are propelling the adoption of micro inverter solar technology. This modular approach allows for greater flexibility in system design, easier expansion, and improved performance under challenging conditions, such as partial shading or module mismatch. The market for microinverter solutions continues to expand, reflecting a global commitment to optimizing solar energy harvest and ensuring grid stability through sophisticated power conversion units.

This article delves into the technical intricacies, application advantages, and market dynamics of the modern pv micro inverter, providing B2B decision-makers and technical professionals with comprehensive insights into this pivotal technology.

Technical Specifications and Manufacturing Process of PV Micro Inverters

A pv micro inverter is a compact device that converts the direct current (DC) output from a single solar panel into alternating current (AC) suitable for grid injection or local consumption. Its core functionality revolves around Maximum Power Point Tracking (MPPT) at the module level, which ensures each panel operates at its peak power output, regardless of the performance of other panels in the array. Key technical parameters include conversion efficiency, typically exceeding 97% for modern units, maximum continuous output power, input voltage range, and various grid compliance standards (e.g., IEEE 1547, VDE-AR-N 4105). Advanced microinverters also feature low Total Harmonic Distortion (THD), ensuring clean power output, and integrated communication modules for remote monitoring.

Manufacturing Process Flow of a PV Micro Inverter

The production of a high-reliability pv micro inverter involves a multi-stage, precision-engineered process designed to meet rigorous performance and durability standards. This ensures a service life often exceeding 25 years, critical for target industries such as residential energy, light commercial, and even niche applications in petrochemical and water supply & drainage where robust power conversion is vital.

- Material Procurement & Incoming Quality Control (IQC): High-grade electronic components (e.g., MOSFETs, IGBTs, capacitors, microcontrollers) and structural materials (e.g., aluminum alloy for enclosures, specialized sealants) are sourced. IQC involves extensive testing to ensure materials meet specifications (e.g., IPC-A-610 for electronic assemblies).

- Printed Circuit Board (PCB) Assembly: Utilizes automated Surface Mount Technology (SMT) and through-hole soldering processes. Components are placed with high precision, followed by reflow soldering. This stage adheres to ISO 9001 quality management standards.

- Enclosure Manufacturing: High-pressure die casting or CNC machining is employed for durable aluminum alloy enclosures. These are often designed for optimal heat dissipation and corrosion resistance, particularly crucial for outdoor installations. Precision machining ensures IP67 or IP68 ingress protection.

- Module Integration & Potting: The assembled PCBs are carefully integrated into the enclosure. A key step for environmental protection is potting, where specialized thermal conductive epoxy resin or silicone is used to encapsulate sensitive electronic components, protecting them from moisture, dust, and vibration. This significantly enhances service life, especially in harsh environments relevant to industries like metallurgy.

- Functional Testing & Calibration: Each microinverter undergoes comprehensive functional testing. This includes MPPT algorithm validation, power conversion efficiency measurements, grid synchronization tests, over-voltage/under-voltage protection, and temperature stress tests. ANSI C62.41 standards for surge protection are often referenced here.

- Burn-in Testing: Products are subjected to extended operation under load at elevated temperatures to detect latent defects and ensure long-term reliability.

- Final Quality Assurance (FQA) & Packaging: A final inspection for physical integrity, labeling, and documentation. Products are packaged for shipment, with attention to protective measures to prevent transit damage.

These meticulous steps ensure that each pv microinverter delivers consistent performance, energy saving capabilities, and exceptional durability, even in challenging environments such as those requiring high corrosion resistance.

Typical Product Specifications: 1-in-1 Balcony Microinverter

| Parameter |

Value/Description |

| Model (Example) |

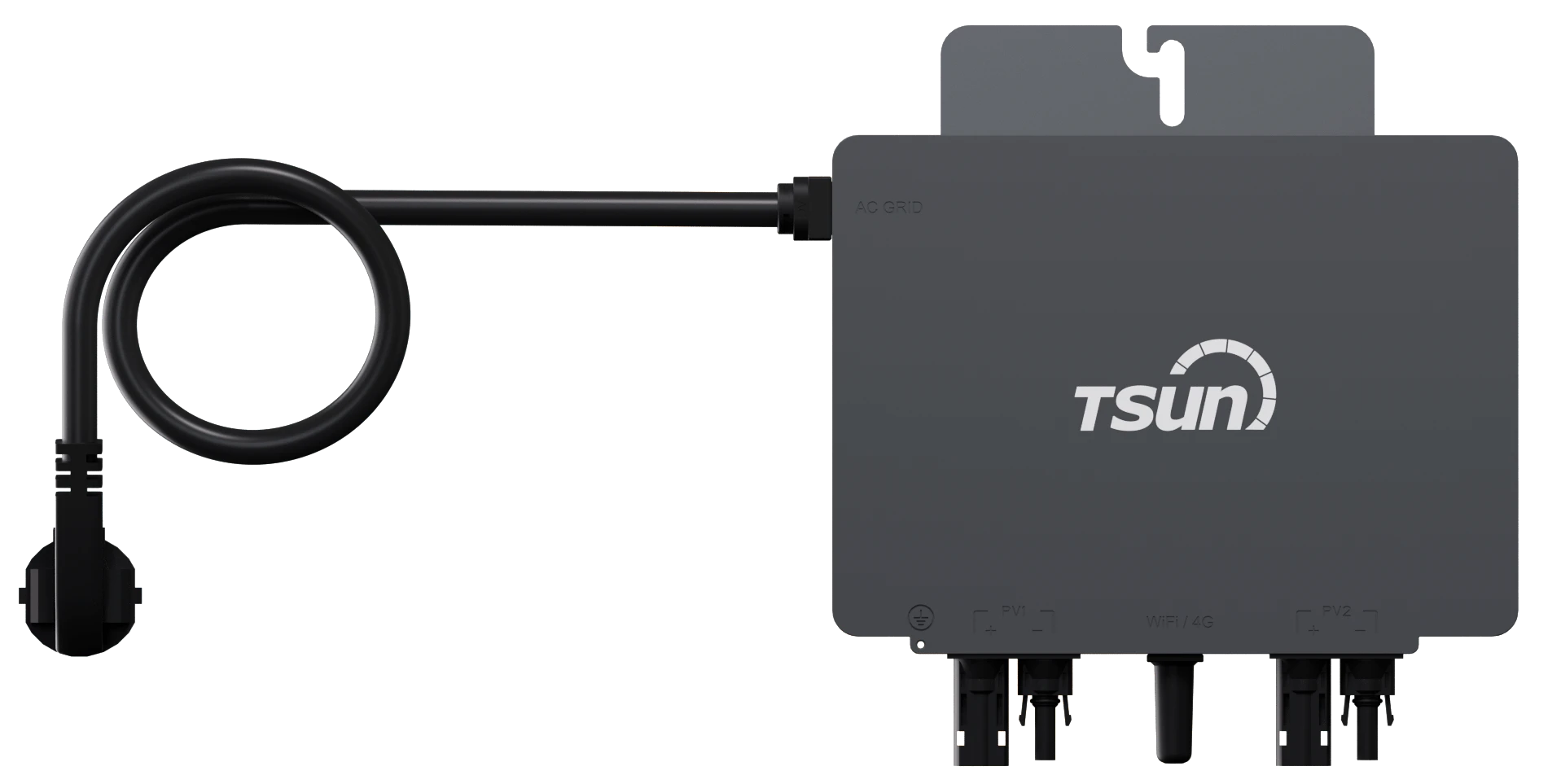

TSUN TSOL-M350 (1-in-1 Balcony Microinverter) |

| Max Input Power |

500W |

| MPPT Voltage Range |

24V-45V |

| Rated Output Power |

350W |

| Max Output Current |

1.52A (230V) |

| Nominal Output Voltage |

230V AC (configurable) |

| Peak Efficiency |

97.3% |

| CEC Weighted Efficiency |

96.5% |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 |

| Communication |

Wi-Fi / PLC (Power Line Communication) |

| Warranty |

10-15 Years (standard) |

| Certifications |

VDE-AR-N 4105, EN 50549, IEC 62109, AS/NZS 4777, UL 1741 |

Technical Advantages and Performance Optimization of Micro Inverter Solar Systems

The fundamental appeal of a micro inverter solar system lies in its ability to circumvent many of the performance limitations inherent in traditional string inverter architectures. By implementing module-level MPPT, each solar panel operates independently, maximizing its energy harvest. This is particularly advantageous in scenarios prone to partial shading, module mismatch, or soiling, which can severely degrade the output of an entire string in a conventional system.

Beyond enhanced energy production, microinverters offer superior safety features. The conversion of DC to AC occurs directly at the panel, eliminating the need for high-voltage DC wiring that runs across the rooftop. This significantly reduces the risk of arc faults and associated fire hazards, addressing a critical concern for both residential and commercial installations. Features like Rapid Shutdown, now mandated in many regions, are inherently integrated into microinverter designs, allowing for quick system de-energization during emergencies.

Furthermore, the modular nature of the pv microinverter system provides unparalleled flexibility. Systems can be easily expanded one panel at a time, adapting to growing energy needs or evolving roof layouts. Granular monitoring at the individual module level allows for precise performance diagnostics, quickly identifying underperforming panels for maintenance and optimizing overall system yield. This level of control and insight is invaluable for operations and maintenance (O&M) teams.

The robust design and potting processes highlighted in the manufacturing section contribute to the exceptional durability of these units. For industrial applications, such as those found in water supply & drainage systems requiring reliable auxiliary power or remote monitoring, the corrosion resistance of the aluminum enclosures and the sealed electronics ensure long-term operation even in humid or chemically aggressive environments. This translates directly into energy saving benefits over the system's lifespan due to sustained high performance and minimal downtime.

Application Scenarios and Real-World Case Studies

The versatility of the pv microinverter allows for its deployment across a broad spectrum of applications, from residential to commercial and even specialized industrial settings. Its inherent advantages make it particularly suitable for challenging installations or those prioritizing long-term performance and safety.

Typical Application Scenarios:

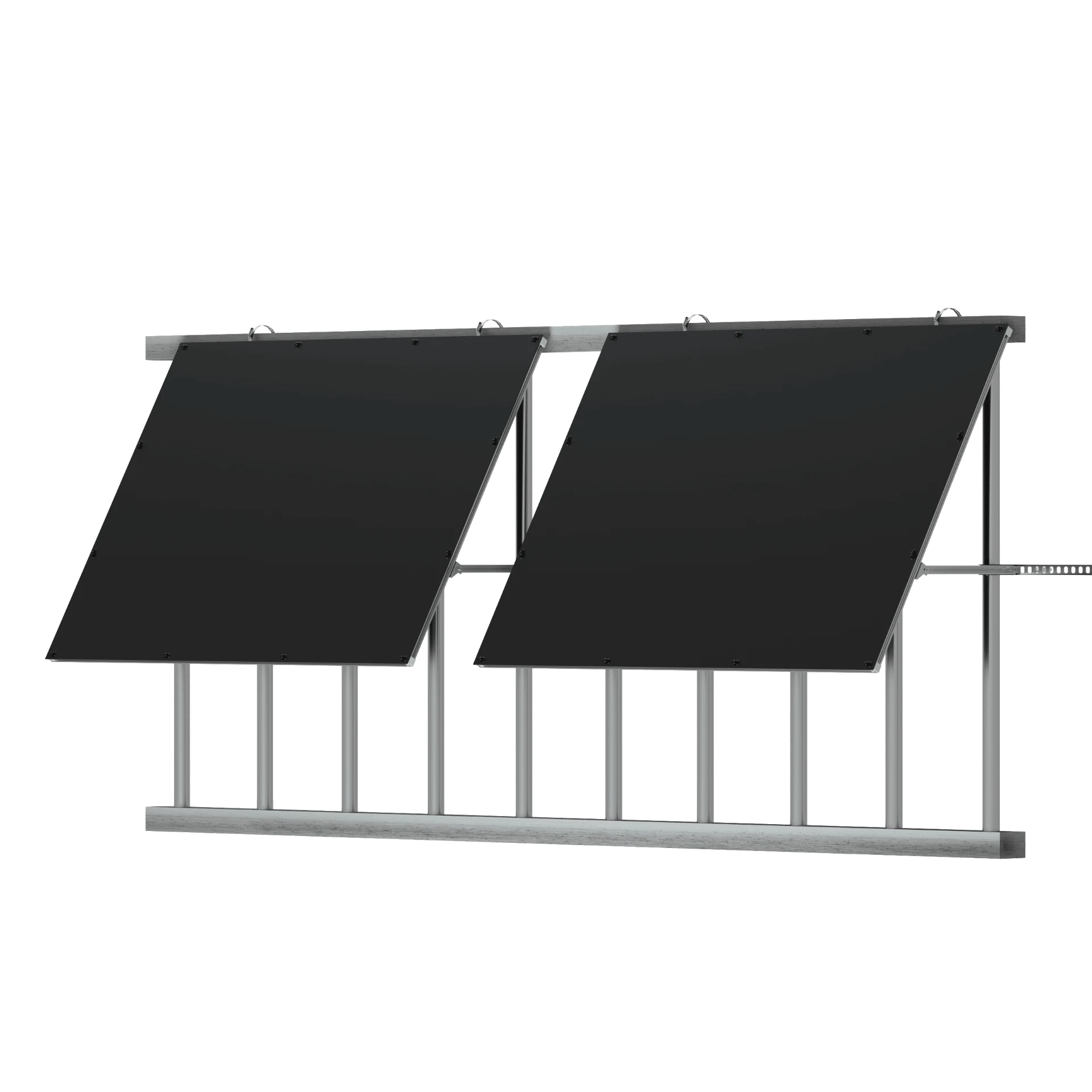

- Residential Balcony Solar Systems: The "1-in-1 Balcony microinverter" concept is gaining significant traction. For urban dwellers with limited roof access, installing a solar cell micro inverter with one or two panels on a balcony railing offers a simple, plug-and-play solution for energy independence. Its compact size and ease of installation are critical here.

- Complex Rooftops: Buildings with multiple dormers, skylights, chimneys, or varying orientations benefit immensely from module-level optimization. Microinverters mitigate the impact of partial shading, ensuring the entire array performs optimally.

- Small to Medium Commercial Installations: Businesses looking for scalable, high-performing solar solutions without the complexities of large DC wiring runs find pv microinverter systems ideal. The modularity also simplifies maintenance and future expansion.

- Critical Infrastructure & Remote Sites: In sectors like petrochemicals or water treatment plants, where energy reliability is paramount, decentralized power generation with high fault tolerance is invaluable. A single microinverter failure affects only one panel, not the entire system.

Case Study: Urban Balcony Solar Deployment

A recent project involved deploying TSUN's 1-in-1 Balcony microinverter to provide supplementary power for apartments in a densely populated urban area. Residents, previously unable to access solar due to building regulations or roof limitations, installed a single 350W PV module connected to a TSUN microinverter on their balconies. The primary goal was to offset standby power consumption and contribute to personal energy independence. Installation was completed by homeowners within an hour, requiring only basic tools and a standard wall outlet connection. The integrated Wi-Fi monitoring allowed residents to track real-time energy production and savings via a mobile app.

Results: Over a six-month period, each balcony setup generated an average of 1.2 kWh per day, effectively reducing household electricity bills by approximately 15-20%. Customer feedback highlighted the ease of installation, the robust build quality of the pv microinverter, and the immediate visible impact on their energy consumption patterns. This demonstrates the viability of distributed, small-scale solar generation made accessible by advanced microinverter technology.

This experience underscores the practical benefits of module-level power electronics for democratizing solar energy, especially in contexts where traditional systems are impractical.

Vendor Comparison and Market Differentiation in PV Microinverters

The global market for pv microinverter solutions is competitive, with several key players offering distinct technologies and features. When evaluating vendors, B2B decision-makers typically assess efficiency, reliability, monitoring capabilities, warranty provisions, and overall cost-effectiveness. While all microinverters aim to provide module-level power optimization, their execution varies, leading to differentiation in specific performance metrics and integrated functionalities.

Key Comparison Parameters:

- Efficiency Ratings: Peak and CEC weighted efficiencies are crucial for maximizing energy yield. Leading brands often achieve 97% or higher.

- MPPT Performance: How quickly and effectively the microinverter tracks the maximum power point, especially under dynamic shading conditions.

- Communication Protocol: Wi-Fi, Zigbee, PLC (Power Line Communication) options impact monitoring setup and reliability.

- Enclosure & Durability: IP rating (e.g., IP67 for outdoor use), materials (e.g., marine-grade aluminum), and potting processes.

- Warranty & Support: Standard warranty periods typically range from 10 to 25 years, with varying levels of customer support and replacement policies.

- Grid Compliance: Adherence to international and regional grid codes (e.g., UL 1741, VDE 0126-1-1, AS/NZS 4777.2).

Microinverter Vendor Comparison Table (Illustrative)

| Feature |

TSUN (Example: 1-in-1 Balcony) |

Vendor X (Premium Residential) |

Vendor Y (Cost-Effective) |

| Max Output Power (Single Module) |

350W |

480W |

300W |

| Peak Efficiency |

97.3% |

97.8% |

96.5% |

| Communication |

Wi-Fi / PLC |

Proprietary Wireless |

Wi-Fi |

| Enclosure Rating |

IP67 |

IP67 |

IP65 |

| Warranty (Years) |

10-15 |

25 |

10 |

| Advanced Features |

Integrated grounding, easy installation |

Microgrid forming, advanced analytics |

Basic monitoring |

TSUN differentiates itself by focusing on ease of installation, robust design for diverse environments, and specific solutions like the 1-in-1 Balcony microinverter, which caters to emerging market segments. While premium brands may offer more complex integrations or longer warranties at a higher price point, TSUN provides a balance of performance, reliability, and cost-effectiveness, particularly for decentralized and residential applications, leveraging its expertise in solar cell micro inverter technology.

Customized Solutions and System Integration

Beyond standard off-the-shelf products, the deployment of pv microinverter technology often benefits from customized solutions tailored to specific project requirements. For B2B clients, this can involve optimizing for unique grid codes, integrating with specific monitoring platforms, or developing solutions for challenging environmental conditions. TSUN, as an experienced provider, specializes in developing bespoke microinverter configurations to meet diverse client needs.

- Tailored Power Outputs: While standard microinverters come in common power ratings, specific projects may require slightly adjusted outputs to match specialized PV modules or local grid regulations.

- Communication & Monitoring Integration: Seamless integration into existing building management systems (BMS) or energy management systems (EMS) is often critical. This may involve custom API development or support for specific communication protocols beyond standard Wi-Fi or PLC.

- Environmental Hardening: For deployments in extreme climates (e.g., coastal areas with high salinity, industrial zones with corrosive atmospheres, or regions with severe temperature fluctuations), enhanced enclosure materials, specialized coatings, or more robust potting compounds can be specified. This ensures the pv microinverter maintains its promised service life and performance.

- Niche Application Design: From powering remote sensors in the petrochemical industry to providing auxiliary power for water purification systems in isolated communities, microinverters can be adapted to serve unique energy requirements. This could include specialized DC input ranges or customized output profiles.

TSUN's engineering team works closely with clients to understand their precise operational context and technical specifications, providing design consultation, prototype development, and rigorous testing to ensure the customized pv microinverter solution delivers optimal performance and reliability for the intended application.

: Expertise, Experience, Authoritativeness, and Trustworthiness

For B2B partners, confidence in a technology provider is built on a foundation of demonstrable expertise, extensive experience, undisputed authoritativeness, and unwavering trustworthiness. TSUN is committed to upholding these pillars in its offering of pv microinverter solutions.

Expertise & Authoritativeness:

Our technical team comprises seasoned engineers with deep knowledge in power electronics, solar energy systems, and grid integration. This expertise is reflected in the advanced design and robust performance of our microinverter products. TSUN's products are certified to rigorous international standards including ISO 9001 for quality management, CE for European conformity, TUV for safety and performance, and UL 1741 for North American grid interconnection. These certifications are not merely badges but represent adherence to stringent testing protocols and validation processes, ensuring our products meet global benchmarks for reliability and safety. We are proud to collaborate with established industry partners, continually advancing the capabilities of solar cell micro inverter technology.

Experience & Trustworthiness:

With years of experience in the renewable energy sector, TSUN has successfully deployed thousands of microinverters in various climates and operational environments worldwide. Our commitment to client satisfaction is demonstrated through long-term partnerships and a comprehensive support framework. We understand that reliability extends beyond product performance to the entire customer journey.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for a bulk order of microinverters?

- A: Standard lead times for bulk orders generally range from 4 to 6 weeks, depending on order volume and current inventory levels. Customized solutions may require additional time for design and prototyping. We provide accurate lead time estimates upon order confirmation.

- Q: What warranty terms do you offer for your pv micro inverter products?

- A: Our standard warranty for the 1-in-1 Balcony Microinverter is 10-15 years, covering manufacturing defects and performance degradation outside specified parameters. Specific project agreements may allow for extended warranty options. Full details are provided with product documentation.

- Q: How does TSUN handle after-sales support and technical assistance?

- A: We offer dedicated after-sales support through multiple channels, including phone, email, and an online portal. Our technical support team is available to assist with installation, troubleshooting, and system optimization. Regional service partners ensure timely on-site assistance where required.

- Q: Are your microinverters compliant with emerging grid regulations?

- A: Yes, our products are designed and continuously updated to comply with the latest international and regional grid interconnection standards, including advanced functionalities required for smart grids and rapid shutdown mandates. Please refer to specific product datasheets for a full list of certifications.

Conclusion: The Future of Distributed Solar with PV Micro Inverters

The journey through the intricate world of pv micro inverter technology reveals a solution that is not merely an incremental improvement but a paradigm shift in solar power conversion. By addressing the inherent challenges of traditional string inverter systems – primarily related to efficiency under varied conditions, safety, and system modularity – microinverters empower a more resilient, efficient, and flexible approach to solar energy generation.

From detailed manufacturing processes ensuring longevity and robust performance in demanding industrial sectors like water supply and drainage, to tailored solutions for complex commercial installations and the burgeoning market of balcony solar, the adaptability of the pv microinverter is undeniable. Its technical advantages, including module-level MPPT, enhanced safety, and granular monitoring, translate directly into higher energy yields, reduced operational risks, and lower lifetime costs for B2B clients.

As the global energy landscape continues its rapid transition towards decentralized renewable sources, the intelligence and reliability offered by advanced pv microinverter solutions position them as indispensable components for the sustainable energy future. TSUN remains at the forefront of this evolution, committed to delivering high-quality, innovative, and trusted microinverter technologies to power a cleaner, more efficient world.

References:

- National Renewable Energy Laboratory (NREL). "Microinverter Technology and its Impact on Photovoltaic System Performance and Safety."

- Institute of Electrical and Electronics Engineers (IEEE). "IEEE 1547: Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces."

- International Electrotechnical Commission (IEC). "IEC 62109-1 and 62109-2: Safety of Power Converters for Use in Photovoltaic Power Systems."

- Fraunhofer Institute for Solar Energy Systems ISE. "Current PV Status and Future Prospects."

- Solar Energy Industries Association (SEIA). "Solar Industry Research Data."

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact Us

Contact Us Monitoring

Monitoring

LEARN MORE

LEARN MORE