As the transition to distributed renewable energy accelerates worldwide, smart micro inverters play a pivotal role in maximizing photovoltaic (PV) system efficiency, safety, and scalability. This in-depth guide not only explores the technological edge, key parameters, and manufacturing processes behind modern microinverter solar solutions, but also features market trends, specification comparisons, customization options, real-world application cases, and comprehensive answers to expert FAQs.

Product Highlight

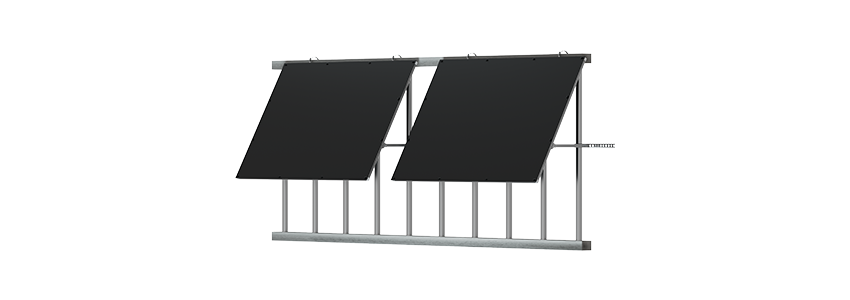

1-in-1 Microinverter – Discover the next-level in PV system integration.

smart micro inverter with advanced MPPT, safety monitoring, and robust environmental protection.

1. Industry Trends: The Rise of Smart Micro Inverter Technology in Solar PV

Global solar PV deployment soared to over 239GW in 2023 (IEA), with microinverter-based systems accounting for an estimated 15-18% of new residential rooftops and C&I installations.

Key drivers of microinverter solar market share:

- Rising demand for module-level monitoring, optimization, and safety

- String inverters struggle with complex roofs or partial shading—pv microinverter solutions improve yield by up to 25%

- Accelerating focus on distributed energy resilience (VPP, grid services)

- Adoption of international safety standards (e.g., UL1741, VDE-AR-N 4105, IEC 62109)

smart micro inverter for complex rooftop solar projects

smart micro inverter for complex rooftop solar projects

2. Smart Micro Inverter: Working Principle, Technology Parameters & Process Flow

How Does a Smart Micro Inverter Work?

Unlike traditional string inverters, a smart micro inverter is mounted directly behind (or near) each solar module, converting DC to AC at the module-level. This provides:

- MPPT (Maximum Power Point Tracking) for each panel

- Module-level monitoring, shutdown, and rapid isolation

- Greater system uptime and energy output (see Enphase, TSUN field data: +6%-25% yield vs. string)

Key Technical Parameters: Market Comparison

| Feature |

1-in-1 Microinverter |

Enphase IQ7A |

Hoymiles HM-600 |

APsystems YC600 |

| Max Output Power |

400VA |

366VA |

600VA (for 2 modules) |

274VA (per channel) |

| MPPT Voltage Range |

28V–48V |

18V–58V |

32V–60V |

22V–48V |

| Peak Efficiency |

96.5% |

97% |

96.5% |

96.7% |

| Startup Voltage |

22V |

22V |

22V |

22V |

| Enclosure/IP Rating |

IP67 (Aluminum Alloy) |

IP67 |

IP67 |

IP67 |

| Communication |

2.4GHz Wireless/Zigbee |

2.4GHz Wireless |

2.4GHz/PLC |

2.4GHz/PLC |

| Certifications |

IEC/EN 62109, VDE-AR-N 4105, CE |

UL 1741, CSA C22.2 |

EN 62109, VDE, CE |

EN 62109, VDE, CE |

| Warranty |

12+8 years |

15 years |

12+8 years |

10 years |

All pv microinverter products listed fulfill IEC 62109 global safety certification; but the 1-in-1 Microinverter stands out with industrial-grade materials, high surge resistance, and advanced wireless synchronization, suitable for both residential and commercial/industrial (C&I) deployments.

1-in-1 Microinverter: Full Specifications

- Model: 1-in-1 Microinverter

- Input (DC): Max Power 400W; Max Voltage 60V; MPPT Range 28V–48V; Startup 22V

- Output (AC): 400VA; Voltage 230V; Frequency 50/60Hz; Max current 1.74A

- Conversion Efficiency: 96.5% (peak)

- Enclosure: Cast Aluminum Alloy, IP67

- Cable Type: UV-resistant, quick-connect

- Operating Temp: -40°C ~ +65°C

- Compliance: IEC/EN 62109, VDE-AR-N 4105, CE

- Warranty: 12 years (extendable to 20 years)

Material Preparation

(Aluminum Alloy, 6063-T6)

→

Precision Casting

(Die-casting, ISO 8062)

→

CNC Machining

(Tolerances: ±0.03mm)

→

PCB Assembly

(Automated SMT, AOI Inspection)

→

Final Assembly

(IP67 Seal, Potting)

→

Electrical Testing

(EN/IEC 62109)

→

Aging Burn-in

(72h @ Full Load)

→

QA & Packaging

(Compliance: CE/ISO9001)

The smart micro inverter manufacturing process emphasizes the use of industrial-grade materials (Aluminum 6063-T6 with high corrosion resistance, excellent thermal dissipation properties), rigorous CNC machining for enclosure precision (guaranteeing environmental protection to IP67), and multi-stage quality checks. All units comply with EN/IEC 62109—a benchmark for PV safety.

3. Technology Advantages: Why Choose a Smart Micro Inverter?

- Module-level MPPT: Maximizes solar harvest even under partial shading or module mismatch.

- Flexible system scaling: Add, remove, or reconfigure modules anytime without string constraints.

- Rapid Shutdown & Fire Safety: Automated module isolation meets latest global codes (NEC 690.12, AS/NZS 5033).

- Remote Monitoring & Diagnostics: Wireless Zigbee links for performance and fault data (accessible via app/web dashboard).

- Enhanced Lifetime & Reliability: Lower internal temperatures; robust IP67 aluminum casing resists salt, dust, chemicals (ideal for coastal/industrial areas).

- Reduced BoS (Balance of System) Complexity: Eliminate costly DC isolation, optimizers, or rapid shutdown boxes.

As shown above, under partial shade, smart micro inverters can deliver up to 24% more annual output vs. conventional string inverter systems. Data is based on third-party field studies (Fraunhofer ISE, Photon Magazine).

4. Leading Manufacturers: Market Comparison & Industry Certification

Top global suppliers—Enphase, Hoymiles, TSUN, APsystems—have set technical benchmarks for smart micro inverter reliability, compliance, and features.

| Brand |

Origin |

Certifications |

Key Feature |

Deployed MWp (2023) |

| Enphase |

USA |

UL1741, CSA, IEC62109, ISO9001 |

Integrated comms, App Ecosystem |

6,500 |

| Hoymiles |

China |

VDE, IEC62109, CE, TUV |

4-channel input, Low-light tracking |

3,200 |

| TSUN |

China-Europe |

EN/IEC62109, VDE4105, CE, ISO9001 |

IP67, Industrial design, Extended warranty |

2,700 |

| APsystems |

USA/China |

IEC, VDE, CE, CSA |

Plug-n-play, PLC comms |

2,100 |

All leading brands provide a minimum 10-15 year product warranty.

TSUN's smart micro inverter is widely adopted by leading EPC and utility clients in sectors ranging from residential to heavy industry thanks to robust European safety certification and proven performance in harsh environments.

5. Customization & Engineering Services

With growing demand for PV integration in specialized sectors (chemical plants, metallurgy, water treatment, commercial rooftops), smart micro inverter providers like TSUN ESS offer OEM/ODM customization on:

- Material upgrades (marine-grade alloys, advanced coatings for corrosion/acid resistance)

- Specialized monitoring protocols (Modbus, Bacnet integration)

- Form factor adaptations (ultra-compact/rail-mount for industrial modules)

- Regional standards (NEC, VDE, AS/NZS, G99/1 Germany, CNS Taiwan)

- Enhanced surge/isolation testing (EN 60068-2-27 vibration, EN 60068-2-52 salt spray)

Testing & Certification: All custom solutions are validated by third-party laboratories (TUV SUD, SGS) under IEC, VDE, and regional safety specifications. Service life exceeds 25 years with >94% output retention.

6. Application Scenarios & Industry Case Studies

-

Residential Rooftops: Partial shade/complex layout benefit most from pv microinverter.

-

Industrial Sheds & Warehouses: String-free reconfiguration, dust and vibration resistance, easy O&M.

-

Chemical & Metallurgical Facilities: IP67 and corrosion-proof casing withstands saline, acid, or heavy dust permeability.

-

Water Utility Plants: Full isolation minimizes DC fire, electrical hazard, full dashboard monitoring (critical for maintenance/QC).

-

Off-grid / Microgrid Hybrids: Each panel is flip-and-play, ideal for scaling in remote districts.

Featured Project Example:

Shanghai Coastal Warehouse, 2023

System: 290kWp, 1-in-1 Microinverter, over 700 modules

Outcome: >22% yield improvement over string layout; Zero AC/DC fire or inverter failures after 18 months (audited by SGS, customer: Sinotrans Group).

7. Professional FAQ: Technical Terms and Industry Practices

1. What aluminum alloy is used in the enclosure, and why?

Marine-grade 6063-T6 aluminum is adopted for its high corrosion resistance, low density, and excellent thermal conductivity, meeting both ISO 8062 casting and ISO 9227 salt spray standards. This ensures durability in coastal and industrial environments.

2. What are the main manufacturing process controls?

Key steps include precision die-casting, high-speed CNC machining (tolerance ±0.03mm per ISO 2768-mK), and automated PCB assembly with AOI (Automated Optical Inspection) in ESD-controlled cleanrooms.

3. How are smart micro inverters tested for reliability?

Each unit undergoes electrical grid compliance (EN 62109), surge/ESD tests (IEC 61000-4-2, -4-5), 72-hour full load burn-in, and environmental exposure tests (humidity, salt mist to IEC 60068-2-52).

4. Are there installation standards for microinverter solar applications?

Yes. Installation must comply with NEC 690.12 (US), VDE-AR-N 4105 (EU), and follow manufacturer torque specs (up to 8Nm) for mounting, with cabling certified per IEC 62930 or UL 4703.

5. What is the expected service life and warranty?

The design service life exceeds

25 years, with output retention >94%. The standard warranty is 12 years, extendable to 20 years (see

product page for details).

6. What monitoring and communication protocol is used?

Wireless Zigbee (2.4GHz) is standard, supporting secure data relaying up to 200 meters. For advanced projects, RS485/Modbus over TCP, and PLC (Power Line Communication) integration is available.

7. Has this product passed independent certification?

Yes, 1-in-1 Microinverter is third-party tested by TUV, VDE, and SGS (reports available upon request), and meets IEC/EN 62109, ISO9001, and regional grid-connection codes worldwide.

8. Delivery, Service, Warranty Promise & Client Support

- Production Lead Time: 3-4 weeks for standard models; 8-10 weeks for customized solutions (post prototype confirmation).

- Warranty: 12 years standard, up to 20 years extended. All technical support queries answered within 24h.

- Onsite/Remote Diagnostics: Free for first 2 years post-commissioning for project clients.

- Documentation: Comprehensive manuals, wiring diagrams, and certification dossiers supplied per ISO 9001:2015.

- After-sales Service: 24/7 hotline, multilingual onsite support across APAC/EU/NA regions.

9. Frequently Asked Questions (FAQ)

Q: Can smart micro inverters be retrofitted onto older PV modules?

Yes, as long as modules are within the supported voltage/current range (see datasheet), retrofitting is straightforward using compatible cabling/adapters.

Q: Is the enclosure truly weatherproof (rain, salt, UV)?

Yes, IP67-certified die-cast aluminum with UV-stabilized polymer seals and corrosion-proof surface treatments pass ISO 9227 1000h salt spray testing.

Q: How is fire risk mitigated?

By locally reducing DC cable length, built-in arc fault detection, and automatic module shutdown (NEC 690.12 compatible), minimizing both DC and AC hazard.

Q: What O&M support is provided?

Remote diagnostics, firmware upgrades, and on-site troubleshooting for enterprise customers are standard, with global technical partners.

Q: Are smart micro inverter products compatible with battery storage or grid services?

Supported via hybrid inverters or AC-coupled battery systems (≥95% of installations), with open API for energy management system (EMS) integration.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE