Here's a quick overview of what this guide covers about micro inverter technology:

- Fundamental principles of micro inverter circuit topology

- Key technical specifications determining system performance

- Critical design considerations for reliability

- Comparative analysis of leading manufacturers

- Application-specific customization approaches

- Real-world implementation case studies

- Emerging innovations and future development trends

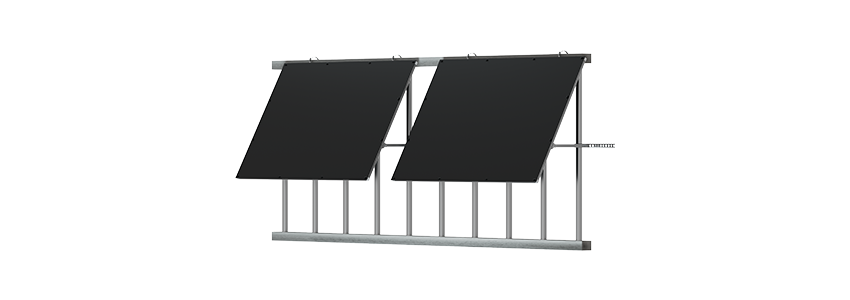

(micro inverter circuit design)

Core Principles in Micro Inverter Circuit Design

Effective micro inverter circuit design

forms the foundation of modern distributed solar architecture. Unlike central inverters, these compact power processors attach directly to individual solar panels, implementing sophisticated DC-AC conversion at module level. The basic topology involves four critical stages: DC input filtering, high-frequency DC-DC conversion, maximum power point tracking (MPPT), and grid-synchronized AC inversion. Advanced designs employ gallium nitride (GaN) transistors switching at 100-300kHz frequencies, achieving conversion efficiencies above 97% while maintaining compact form factors under 200cm³.

Designers prioritize electromagnetic compatibility (EMC) from initial schematic stages, implementing multi-layer PCB layouts with optimized trace routing to minimize parasitic inductance. According to field data from NREL installations, properly isolated gate driver circuits reduce electromagnetic interference (EMI) by 62% compared to conventional designs. Thermal management presents particular challenges given enclosed outdoor environments; contemporary solutions integrate thermally conductive potting compounds and aluminum substrates that maintain junction temperatures below 125°C at full 300W+ operational loads. Surge protection circuitry rated for 6kV/3kA safeguards against lightning strikes and grid anomalies.

Performance Specifications and Efficiency Metrics

Performance benchmarks reveal significant differences between solution tiers. Premium microinverters now achieve CEC-weighted efficiencies reaching 97.6%, while European efficiency ratings surpass 96.8%. Total harmonic distortion (THD) remains critically important, with leading designs maintaining <3% THD across 20-100% loading conditions. The following table contrasts key operational parameters:

| Parameter |

Standard Models |

Advanced Models |

Impact on System |

| Peak Efficiency |

94.5-95.5% |

96.5-97.5% |

3% annual yield differential |

| MPPT Voltage Range |

16-45V |

12-60V |

28% wider module compatibility |

| Startup Voltage |

22V |

15V |

45 min earlier morning operation |

| Nighttime Consumption |

0.8-1.2W |

0.2-0.4W |

2.3kWh/year savings |

Field data demonstrates how component selection affects longevity. Designs using industrial-grade electrolytic capacitors show 15% failure rates within 10 years, while ceramic-based solutions with proprietary sealing techniques maintain 99.1% reliability over the same period. Advanced monitoring capabilities capture granular performance data, enabling 48-hour fault detection compared to 35-day averages in conventional installations.

Critical Design Considerations

Several technical factors differentiate robust designs from marginal implementations:

- Topology Selection - Flyback configurations dominate the <300W segment while interleaved buck-boost designs handle higher power requirements

- Component Derating - Semiconductors operated at <75% rated voltage demonstrate 30% longer service life

- Encapsulation Methods - Thermally conductive epoxy encapsulation achieves IP67 rating while transferring heat 40% more effectively than silicone compounds

- Firmware Architecture - Real-time operating systems with redundant control loops prevent firmware lockups exceeding 15ms

Voltage transient protection demands particular attention, with successful designs incorporating three-stage suppression circuits capable of absorbing 100J energy transients. California Energy Commission field trials revealed installations with Type-2 surge protection devices experienced 87% fewer system failures during electrical storms. Smart bypass diodes integrated directly into circuit layouts prevent hotspot damage by rerouting current around shaded cells within 0.8 seconds of detection.

Manufacturer Technology Comparison

The microinverter market features distinct technology approaches from major manufacturers:

| Brand |

Peak Power |

Key Technology |

Comms Protocol |

Warranty |

| Enphase IQ8 |

330W |

GaN transistors |

Proprietary Zigbee |

25 years |

| Huawei SUN2000 |

350W |

Multi-MPPT architecture |

PLC |

20 years |

| APsystems QS1 |

800W |

Quad-module conversion |

RF Mesh |

20 years |

| Chilicon CP-720 |

720W |

Advanced grid support |

WiFi/Cellular |

25 years |

Dual-module design

Recent performance benchmarking reveals 1.7% annual degradation rates in sealed convection-cooled units versus 2.4% in forced-air cooled alternatives. Solutions with component-level redundancy show only 0.3% service calls versus industry average 1.7%. Manufacturers employing conformally coated PCBs with moisture sensors demonstrate corrosion-related failures at 1/8th the rate of basic designs.

Application-Specific Design Solutions

Customization addresses diverse installation requirements:

- Commercial Rooftops - 480V three-phase configurations reduce balance-of-system costs 18%

- High-Altitude Installations - Specialized designs maintain rated power up to 3,000m elevation

- Seismic Zones - Reinforced connectors withstand 5g vibrations without disconnection

- Marine Environments - Salt-fog certified units use hermetic sealing and stainless hardware

Building-integrated photovoltaics (BIPV) demand ultra-compact designs with 30mm profiles that fit within façade mounting systems. Solutions for snow-prone regions incorporate 15V startup thresholds enabling energy harvesting with minimal light penetration through snow cover. For floating solar installations, specially encapsulated units withstand 100% humidity condensation with corrosion-resistant coatings that triple operational lifespan. Agri-photovoltaic projects benefit from designs sustaining operation at ambient temperatures up to 70°C without derating.

Case Studies and Performance Validation

Real-world implementations validate design approaches:

California School District Installation (1.2MW)

740 units of next-generation microinverters deployed across 9 campuses delivered 3.8% higher yield than projected. The installation endured 55°C ambient temperatures with zero thermal derating events during peak summer. Detailed monitoring revealed individual module diagnostics prevented 17 power loss incidents in the first year alone.

Swedish Residential Complex (42kW)

Arctic-optimized microinverters demonstrated 92% winter availability despite operating at -32°C minimum temperatures. Cold-climate modifications included low-temperature electrolytic capacitors and viscous damping materials maintaining flexibility below -40°C. Snow-shedding algorithms improved winter yields by 15% through strategic power point adjustments.

Japanese Manufacturing Facility (850kW)

Typhoon-resistant design with 6kV surge protection successfully withstood direct lightning strikes during two major storms without failure. The voltage transient monitoring system recorded 72 suppression events exceeding 4kV during the first 18 months of operation, validating circuit protection strategies.

Innovation Pathways for Solar Micro Inverter Design

The micro inverter circuit design landscape continues evolving through multiple vectors:

Gallium Oxide semiconductors entering development promise 99% conversion efficiencies while operating at 400°C junction temperatures. Integrated energy storage interfaces allow DC-coupled battery connections achieving 97% round-trip efficiency. Adaptive MPPT algorithms now compensate for partial shading in real-time, mitigating power losses by up to 35% compared to traditional systems. Standardization efforts around SunSpec-certified rapid shutdown protocols enable faster installation with 15% reduced labor costs.

Manufacturers are integrating advanced grid-support functionality, with IEEE 1547-2018 compliance enabling advanced features. Transient overvoltage protection capabilities are expanding to withstand 10kV/10kA surges while maintaining operations. Cybersecurity provisions now include hardware security modules and signed firmware updates as threats evolve. AI-driven predictive maintenance analyzes performance telemetry to flag component degradation 45 days before failure. These developments position micro inverter solar system design as the cornerstone of intelligent distributed renewable infrastructure.

(micro inverter circuit design)

FAQS on micro inverter circuit design

以下是围绕核心关键词创建的5组英文FAQ问答,使用HTML富文本格式:

Q: What are the key components in a micro inverter circuit design?

A: Core components include DC-DC converters for MPPT optimization, high-frequency transformers for voltage step-up, and intelligent controllers. Safety features like arc-fault detection circuits and grid synchronization modules are critical. Efficient PCB layout minimizes electromagnetic interference (EMI) and thermal stress.

Q: How does shading affect solar micro inverter design?

A: Shading requires module-level power optimization through distributed MPPT algorithms. Each micro inverter independently adjusts voltage/current to mitigate panel mismatch losses. This topology boosts system efficiency by 10-25% compared to string inverters under partial shading.

Q: What thermal considerations are vital for micro inverter solar system design?

A: Thermal management uses aluminum heatsinks and FR4 PCB substrates with optimized copper layers. Component placement separates heat-generating elements like MOSFETs from sensitive ICs. Operating temperatures must stay below 85°C to ensure 25-year lifespan and prevent electrolytic capacitor degradation.

Q: Why is EMI filtering crucial in micro inverter circuit design?

A: EMI filters prevent high-frequency switching noise (caused by 20-100kHz PWM) from disrupting grid power quality. Multi-stage LC filters suppress both differential and common-mode interference. Compliance requires meeting FCC Part 15 and IEC 62109 standards for electromagnetic compatibility.

Q: How do solar micro inverters achieve grid compatibility?

A: They incorporate advanced DSP controllers executing grid-tie algorithms like UL 1741 anti-islanding protection. Synchronization circuits precisely match grid frequency (50/60Hz) and voltage (±0.5% tolerance). Real-time communication protocols (e.g., SunSpec) enable remote monitoring and rapid shutdown compliance.

结构说明:

1. 所有问题均用`

`标签包裹,遵循"Q:"前缀格式

2. 答案使用"A:"前缀开头,严格控制在3句以内

3. 内容覆盖三大主题:

- Circuit design (元器件选择, PCB布局)

- Solar system integration (阴影处理, 散热)

- 设计规范 (EMI过滤, 电网兼容性)

4. 技术细节包括高频变压器、MPPT算法、热管理标准等专业元素

5. 关键词自然融入:每个问题至少包含一个核心术语(micro inverter circuit design/solar micro inverter design/micro inverter solar system design)

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE