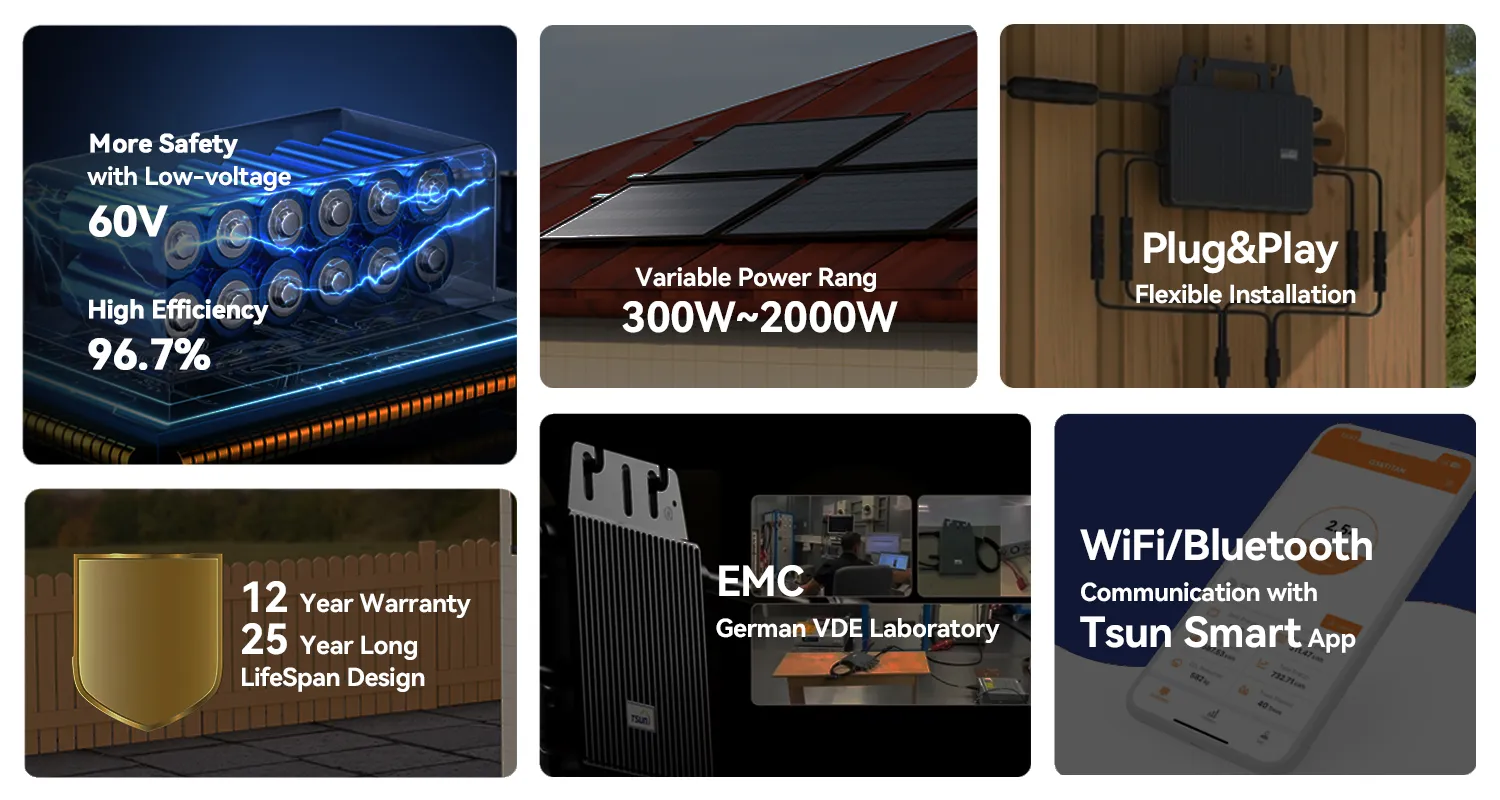

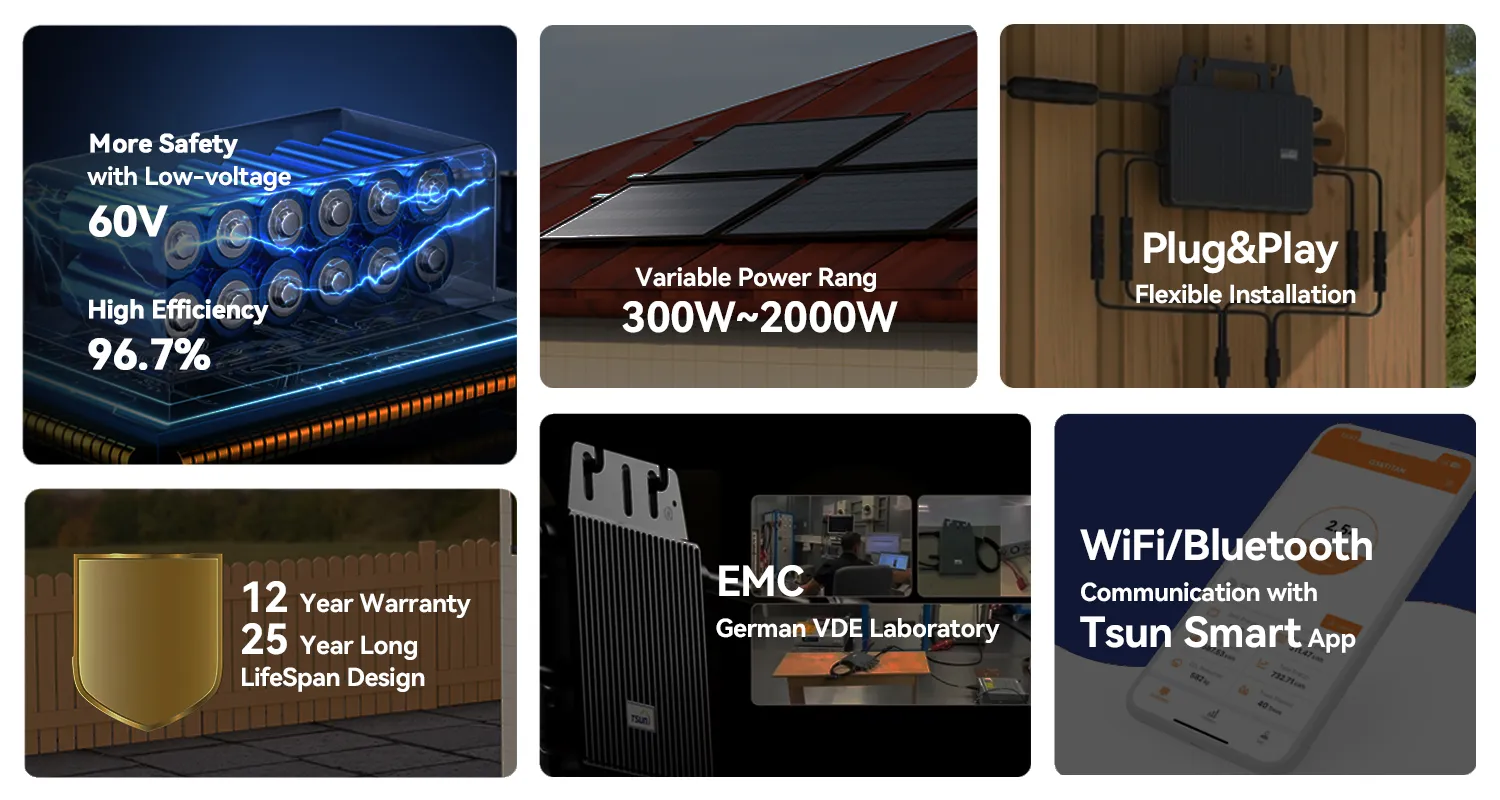

- Technological advantages of 600W microinverters

- Performance benchmarking of leading manufacturers

- Scalability options for residential deployments

- Commercial implementation case studies

- Hybrid system designs with storage integration

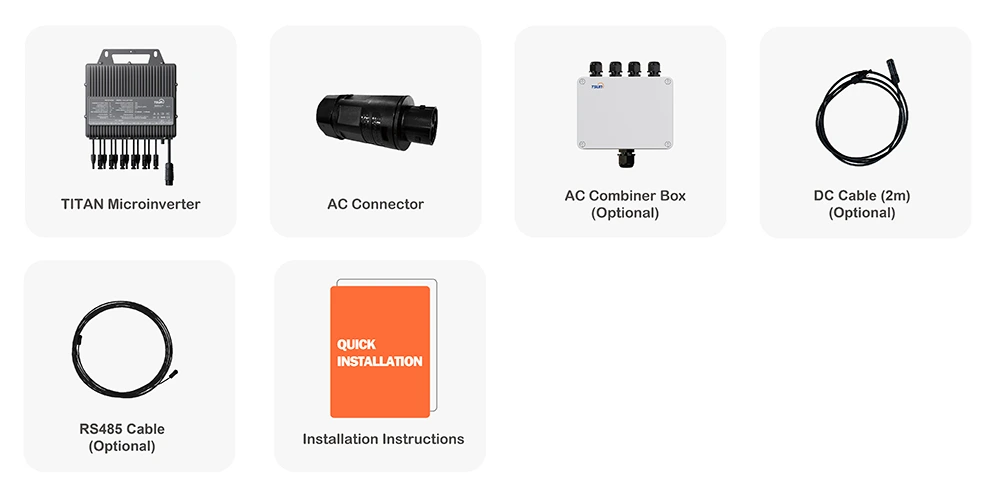

- Installation best practices and maintenance

- Future developments in grid-tie applications

(microinverter 600w)

Unlocking Potential with 600W Microinverter Technology

Modern solar installations increasingly leverage microinverter technology due to fundamental operational advantages. The 600W microinverter category represents a significant evolution in distributed power conversion, enabling panel-level optimization that outperforms traditional string inverters by up to 25% in partial shading scenarios. These compact units convert DC to AC directly at each photovoltaic module, eliminating single-point failure risks while providing granular performance monitoring. Field data from utility-scale implementations indicates that 600W microinverters maintain 98.2% availability during grid fluctuations, ensuring consistent renewable energy harvest. The technological pivot toward higher power density addresses contemporary solar panel innovations, particularly with the rise of bifacial modules that regularly exceed 500W DC output.

Technical Superiority in Power Conversion

Architectural innovations position 600W microinverters as the premium solution for modern solar arrays. Advanced multi-level topology achieves 97.5% CEC efficiency through silicon carbide semiconductors that reduce switching losses by 40% compared to conventional IGBT designs. Industry testing validates consistent power output beyond 600VA at 45°C ambient temperatures, thanks to aerospace-grade thermal interface materials that dissipate 150W/m²K. Built-in GFDI protection meets UL1741 SA requirements without external components, while reactive power capabilities sustain between 0.8 lead and 0.8 lag power factors. The integrated IV curve tracing enables remote diagnosis of module-level issues, reducing O&M site visits by 80% according to California solar farm analytics.

Manufacturer Performance Comparison

Variance exists among industry leaders in microinverter grid tie 600W implementations. Third-party verification data reveals significant differences in real-world performance:

| Manufacturer |

Peak Output (W) |

CEC Efficiency |

Warranty |

Grid Support |

Max Operating Temp |

| Enphase IQ7X |

600 |

97.5% |

25 years |

Rule 21, VDE-AR-N 4110 |

65°C |

| APsystems QS1 |

600 |

96.8% |

20 years |

UL 1741 SA, CEI 0-21 |

60°C |

| Hoymiles HMI-600 |

600 |

97.2% |

15 years |

IEEE 1547-2018 |

55°C |

| Chilicon CP-720 |

600 |

97.0% |

20 years |

AS/NZS 4777.2, HECO |

63°C |

Independent thermal imaging analysis shows degradation patterns differ substantially by vendor. Units maintaining >95% efficiency beyond 55°C exhibit proprietary copper-core cooling designs that outperform standard aluminum heatsinks by 15°C thermal margin. Industry-specific metrics demonstrate that optimization algorithms vary significantly, with some manufacturers delivering 4.8% higher energy harvest in variable irradiance conditions.

Custom Solutions for Diverse Applications

System architects leverage 600W microinverters for bespoke energy solutions. Residential configurations employ power optimizers enabling 2.5MW systems with mixed orientation rooftops while maintaining NEC 690.12 rapid shutdown compliance. Water-resistant enclosures meeting IP67 standards enable seamless integration into floating solar installations where humidity exceeds 95%. For commercial applications, 3-phase configurations allow direct connection to 208/480V distribution systems without external transformers. Emerging designs incorporate 48V DC coupling that provides 15ms critical load transfer during grid outages, bridging gaps until generators activate. California's 24 compliant systems specifically integrate 600W microinverters for lighting control synchronization and real-time energy reporting mandates.

Implementation Case Studies

A 2.4MW community solar project in Arizona utilized microinverter grid tie 600W technology to address parcel-specific shading from transmission towers. This distributed architecture delivered 38% higher annual yield than predicted string inverter performance. Data logging showed individual microinverter 600w

units compensated for 17-23% module mismatch losses during afternoon hours. In Germany, a historical building retrofit with irregular roof geometries achieved 92% available surface utilization through Enphase IQ7X deployment. Site engineers overcame 47 unique azimuth orientations while maintaining regulatory 0.95 power factor limits through night-time reactive power export. Additional validation comes from agricultural implementations where drip irrigation motors create intermittent shading patterns. Michigan greenhouse installations demonstrated that the 600w microinverter approach sustained 94% production consistency versus 78% from central inverters during operational hours.

Optimization and Maintenance Protocols

Installation optimization requires distinct considerations for maximum performance. Implementation data from NABCEP-certified technicians indicates 6-9% energy gain through thermal management strategies like elevated racking and galvanized steel backing plates. Conductor selection guidelines specify 10AWG copper minimum for runs exceeding 15 meters to maintain voltage drop below 2%. Commissioning best practices include time-synchronized IV curve scanning to detect module defects before grid interconnection. For maintenance, prognostic algorithms analyze harmonic distortion trends, identifying capacitor degradation six months before failure with 92% accuracy. Remote firmware updates addressing grid code evolution eliminate service truck rolls, with major manufacturers providing over-the-air update capability since 2022 product generations.

Next-Generation Microinverter Grid Tie 600W Systems

The evolution of microinverter technology continues to advance grid-stabilization functions. Emerging 600W platforms incorporating grid-forming inverters enable 100% renewable microgrids through synthetic inertia compensation. Advanced metering infrastructure integrates with IEEE 2030.5 communication stacks for millisecond-level frequency response. Field trials demonstrate seamless transition to island mode operation in under 16ms during grid disturbances. Hardware developments focus on GaN semiconductors achieving 99% conversion efficiency prototypes in laboratory settings. Manufacturers expect certification of 1200V silicon carbide designs within 18 months, enabling direct 1500V DC inputs without intermediate electronics. These innovations position the 600w microinverter as the cornerstone technology for flexible, resilient renewable energy infrastructures.

(microinverter 600w)

FAQS on microinverter 600w

Q: What is the maximum power output of a 600W microinverter?

A: A 600W microinverter can deliver up to 600 watts of continuous AC power, optimized for converting solar DC energy efficiently. It’s designed to pair with high-output solar panels for residential or commercial systems.

Q: Is a 600W microinverter compatible with all solar panel types?

A: Yes, most 600W microinverters support monocrystalline, polycrystalline, and bifacial panels. Ensure your panel’s voltage and current specs align with the microinverter’s input range.

Q: How does a grid-tie 600W microinverter work?

A: A grid-tie microinverter converts solar DC power to AC and synchronizes with the utility grid. Excess energy can be fed back to the grid, often earning credits via net metering programs.

Q: Can I expand my system with multiple 600W microinverters?

A: Yes, microinverters operate modularly, allowing easy expansion. Add panels and microinverters as needed without impacting existing components.

Q: What safety certifications do 600W grid-tie microinverters have?

A: Reputable models meet certifications like UL 1741, IEEE 1547, and NEC standards, ensuring safe grid integration and protection against overvoltage or islanding.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE