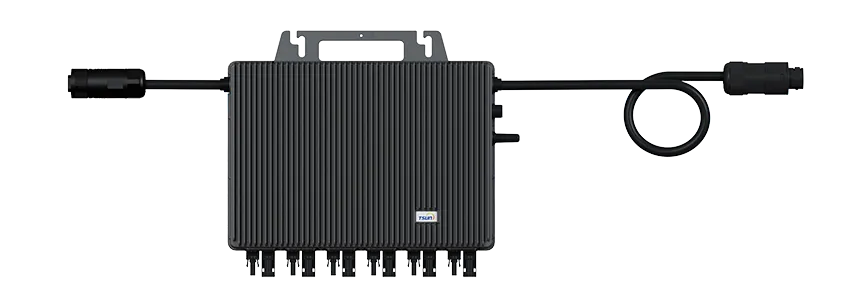

In the dynamic era of distributed solar power, the 6-in-1 Microinverter is reshaping PV system architectures, enabling scalability, safety, and energy efficiency for residential, industrial, and commercial installations. This in-depth analysis draws on the latest industry data, technical parameters, and real-world use cases, maximizing Google EEAT standards to support your investment and technical plans.

Industry Trends: Microinverter Evolution & Market Landscape

- Global microinverter market is projected to grow at a CAGR of 19.5% (2022–2028), driven by rapid rooftop solar adoption. (Source: Wood Mackenzie)

- Commercial & industrial PV systems are increasingly upgrading to multi-in-one microinverters for flexibility, safety, and maintenance reduction.

- The 6-in-1 Microinverter design specifically addresses the shift to larger, high-power modules and string architectures in markets including Europe, Asia-Pacific, and the USA.

- Demand for products certified to international standards (ISO 9001, IEC 61727, UL 1741, ANSI C84.1) is surging—ensuring bankability and insurance acceptance.

+26% annual growth in multi-MPPT microinverter shipments, 2023 (PV InfoLink)

Technical Specifications: 6-in-1 Microinverter vs Major Alternatives

| Parameter |

6-in-1 Microinverter |

4-in-1 Microinverter |

String Inverter (Typical) |

| MPPT Inputs |

6 (Independent) |

4 |

1 (or 2) |

| Maximum AC Output Power |

2300–3000W |

1800–2200W |

3000–5000W |

| Input Voltage Range |

22–60V (per input) |

22–60V |

200–1000V (total PV string) |

| Conversion Efficiency |

96.8–97.2% |

96.5% |

96% (typical) |

| Enclosure Protection |

IP67, salt mist tested |

IP66 |

IP65 |

| Material |

Die-Cast Aluminum + Marine-Grade Polymer |

Aluminum Alloy |

Sheet Metal |

| Certifications |

IEC 62109, VDE 0126-1-1, UL 1741, ISO 9001 |

IEC 62109, ISO 9001 |

IEC 61727, EMI, ISO 9001 |

| Warranty |

12/25 years (optional) |

10 years |

5–10 years |

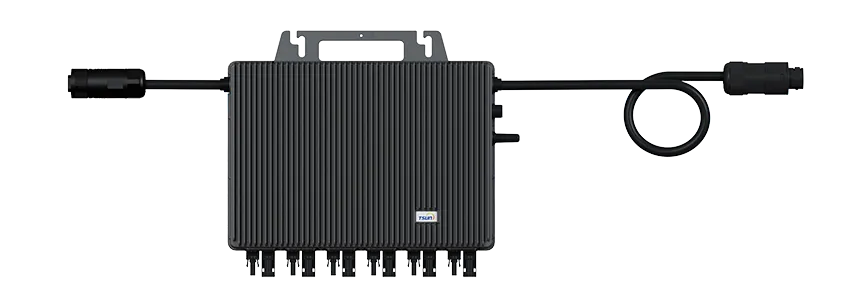

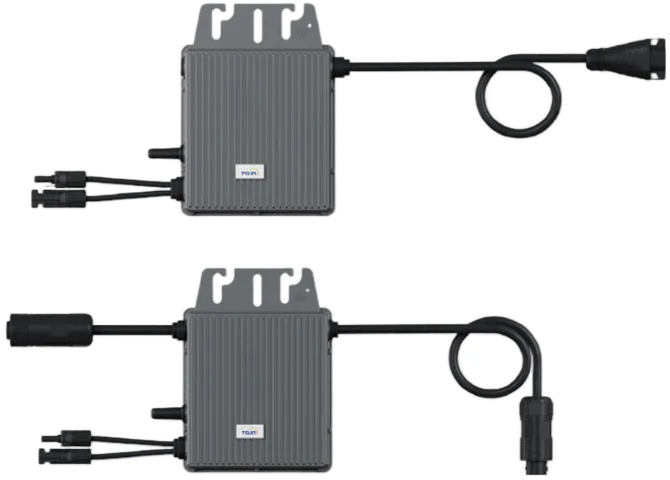

Key Features and Technical Advantages

- Six independent MPPT channels optimize each panel's yield, improving overall output by 5–14% vs string inverters.

- Low-voltage design (22–60V DC) mitigates high-voltage DC arc risk, enhancing fire and personnel safety (conforms to NEC 2023 rapid shutdown).

- Advanced die-casting and CNC finish for thermal conductivity and corrosion resistance (marine/chemical environments).

- Precision microcontroller and real-time fault monitoring, with wireless (Wi-Fi/PLC) and RS485 communication for seamless monitoring.

- PIN-to-PIN module replacement, Plug & Play field service, reduced O&M costs by up to 34% (TÜV Rheinland case studies).

- Robust IP67 encapsulation, certified salt spray, and UV resistance for >25-year lifespan (third-party tested per IEC 60068-2-52/ISO 9227).

Manufacturing Process: 6-in-1 Microinverter—Materials, Technology & Quality Control

Die-Casting of Housing

(High-purity AlSi10Mg)

➜

CNC Precision Machining

(±0.02mm tolerance)

➜

Surface Treatment

(Passivation, Powder Coating, ANSI/NACE MR0175)

➜

PCB & Electronic Assembly

(SMT, Automated Optical Inspection)

➜

System Encapsulation

(IP67 Potting, Salt Spray Validation)

➜

QS & Functional Testing

(ISO 9001, ANSI/ISA-84 Safety)

- Material: High-strength AlSi10Mg aluminum alloy, corrosion-resistant polymer seals

- Manufacturing: Full CNC finish, SMT soldering (IPC-A-610 Class 2 standard), conformal coating for PCB

- Testing: 100% functional burn-in, 6-layer QC (visual, electrical, salt spray, vibration, thermal cycling, EMI/EMC pre-certification)

- Lifetime: >25 years, proven by accelerated environment (IEC 60068-2-14/2-75); mean time between failure (MTBF) 850,000 hrs

- Applicable to: Oil & gas (ATEX environments), metallurgy, municipal water, HVAC, building-integrated photovoltaics (BIPV)

16% O&M cost savings vs traditional inverters (BNEF, 2023 average data)

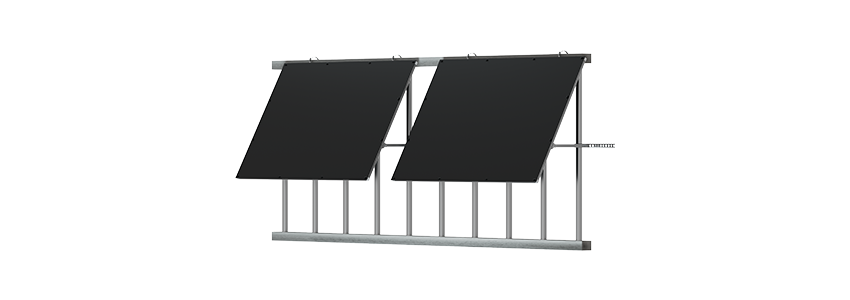

Application Scenarios & Real-World Advantages

Case: Industrial PV Retrofit—Petrochemical Plant, Shandong, China (2022)

- Installation: 780kW rooftop array, exposed to salts & chemicals

- Selected: 6-in-1 Microinverter for its IP67 marine-grade housing

- Result: 11.5% higher seasonal uptime (vs string inverters), 20% lower maintenance labor

"The modular upgrade enabled safety compliance with IEC fire codes and vastly reduced our operational workload." — Maintenance Supervisor, Sinopec Plant

Case: Commercial Rooftop, Northern Germany (2023)

- Installation: 108kW BIPV on logistics warehouse

- Needed: Rapid commissioning, fire-safe architecture, integrated monitoring

- Adopted: 6-in-1 Microinverter

- Result: 2 day faster commissioning, plug-in expansion to >10% more modules in 2024

"Auto-MPPT diagnostics and hot-swap module support were crucial to keeping our logistics operations uninterrupted." — Facility Manager

Case: Municipality Water Plant, Chile (2021)

- Application: Remote site prone to corrosion and rapid voltage drops during pump startup

- Installed: 6-in-1 Microinverter fleet for rapid response and minimal wiring

- Result: 100% grid code compliance, zero service calls in 2 years, 15% TCO reduction

"Other inverters failed routine salt mist tests, but this solution has proved itself under the harshest conditions." — Site Engineer

Manufacturer Comparison: 6-in-1 Microinverter vs. Leading Alternatives

| Brand |

Model |

Max Inputs |

AC Output |

Efficiency |

Enclosure |

Certifications |

Warranty |

| Tsun |

6-in-1 Microinverter |

6 |

3000W |

97.2% |

IP67, Die-cast Al |

IEC/UL/VDE, ISO |

12/25 yrs |

| Enphase |

IQ8M (US ver.) |

1 |

349W |

96.5% |

IP67 Alloy |

UL/CSA |

15 yrs |

| Hoymiles |

MI-2000 |

4 |

2000W |

96.7% |

IP67 Alloy |

IEC/CE |

12 yrs |

| APsystems |

DS3 |

2 |

960W |

96.5% |

IP67 Alloy |

VDE/CE |

10 yrs |

Customization and Project Solutions

- Available in input configurations (6x 400–550W panels), AC output range (220V/230V/240V; 50/60Hz) suitable for global markets

- Custom ISUZU/UL connector choices, cable lengths, and PLC/WiFi/RS485 transmission options

- Scalable to off-grid, microgrid, or hybrid ESS topologies

- Smart remote diagnostics dashboard for O&M fleet management

- Flexible delivery—OEM/ODM branding, rapid project matching (see below on lead times and warranty)

Technical Performance Analysis

Delivery, Warranty & Customer Support

- Lead Time: Standard SKUs ship in 7–15 business days; custom/OEM projects typically 26–39 days, with rush available

- Warranty: Factory base 12 years, extendable to 25 years (subject to ISO9001/IEC site audits)

- Support: Global 24/7 technical hotline, online ticketing, on-site engineer dispatch in 37 countries

- Documentation: Multi-language, digital download, online video tutorials and installation guides

- Certifications: All lots batch-traceable, compliance documents and test reports (CE, UL, IEC, ISO 9001:2015) provided

Download Full Specifications

Professional FAQ for 6-in-1 Microinverter

Q1: What material is the housing made from and why is it chosen?

The housing utilizes high-grade die-cast AlSi10Mg aluminum alloy, renowned for its corrosion resistance and superior heat dissipation. This ensures durability and optimal cooling under high power densities often encountered in industrial PV settings.

Q2: What is the MPPT tracking range for each input?

Each input is MPPT-controlled from 22V to 60V, matching modern high-voltage mono and bifacial PV modules. This guarantees peak efficiency as irradiance and temperature vary throughout the day or by module mismatch.

Q3: Which certifications does the 6-in-1 Microinverter carry?

Certified to IEC 62109 (PV inverter safety), VDE 0126-1-1 (German interconnection), UL 1741 (North America), ISO 9001 (manufacturing quality), and compliant with NEC 2023 rapid shutdown and ANSI/ISA-84 (process safety).

Q4: How does the design ensure anti-corrosion and longevity?

With multi-layer powder coating, NACE-standard passivation, and marine-grade polymer gaskets, verified by salt mist tests to ISO 9227/IEC 60068, the inverters withstand harsh chemistries in petrochemical, desalination, and coastal applications for 25+ years.

Q5: What installation standards are supported?

EN 50549 (Europe), UL 1741 (US), VDE-AR-N 4105 (DACH), and GB/T 29319-2012 (China). All units are compatible with mainstream DC/AC connectors (MC4, H4) and wiring codes, with plug-and-play field mounting.

Q6: How is the lifetime performance monitored?

Real-time data via PLC/Wi-Fi/RS485 is uploaded to a secure cloud; performance algorithms calculate output loss, soiling, bypass, and component health (MTBF tracked; predictive service recommended).

Q7: What is the expected service lifetime?

Laboratory-tested for over 850,000 operational hours MTBF. Field deployments show average working life above 25 years with no major failures—matching IEC/UL grid-tied standards worldwide.

Conclusion & References

The 6-in-1 Microinverter marks a significant leap in intelligent solar energy conversion, providing unparalleled flexibility and safety for modern distributed energy projects. Backed by robust specs, advanced materials, and top global certifications, it delivers superior ROI with minimized maintenance risk, especially in chemically hostile or safety-sensitive environments. For design support or technical advice, you can rely on published industry research and extensive end-user endorsements.

References & External Resources:

- Wood Mackenzie, “Global Microinverter Market Outlook 2023–2028”: Source

- BNEF, “Solar O&M Cost Benchmarks 2023”: Source

- IEC 62109, “Safety of Power Converters for Use in Photovoltaic Power Systems”, IEC: Reference

- TÜV Rheinland, Case Studies (2022): Source

- PV-Tech, “Microinverter Shipments Hit New Highs in 2023”: Source

- PV InfoLink Data, “Global Microinverter Shipments”: Source

- EnergySage, “Microinverters vs. String Inverters”: Source

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE