The robust integration of solar energy and decentralized power generation is fueling rapid development of ac micro inverter technology. As distributed solar systems continue to boom globally, the market for solutions such as micro inverter solar kits, micro inverter systems, and advanced solar cell micro inverter units has expanded at an unprecedented pace. This guide explores industry trajectories, dives into cutting-edge technologies and manufacturing, compares product options with critical data, and presents practical scenarios—providing both professionals and corporate buyers a comprehensive reference for selecting and deploying smart microinverter solar solutions.

Industry Trends & Market Insights: AC Micro Inverter

The global ac micro inverter market has witnessed exponential CAGR growth of 22.6% (2020-2024), according to EIA and Allied Market Research. Major drivers include panel-level optimization, modular design for residential and commercial sectors, and grid flexibility to meet net-zero targets.

| Region |

2023 Installed Capacity (MW) |

Projected CAGR (2024-2028) |

Primary Application |

| North America |

7,900 |

21.2% |

Residential Rooftop, Community Solar |

| Europe |

5,800 |

23.5% |

C&I, Residential |

| APAC |

10,300 |

25.7% |

Utility, Distributed Solar |

| Rest of World |

2,400 |

19.3% |

Industrial, Off-grid |

According to IEA's 2024 Online Solar Market Review, decentralized renewables will outpace centralized generation in new connections by 2026, directly boosting the adoption of micro inverter solar kit and micro inverter system configurations.

Technical Overview: AC Micro Inverter Architectures and Advantages

AC micro inverters are power electronics devices that convert DC output from solar panels into grid-compliant AC—at the individual module level. By offering panel-level maximum power point tracking (MPPT), safety shutdown, and modular installation, these devices significantly increase energy yield and system resilience. Key technical merits:

- Reliability: Eliminates single points of failure present in string inverter setups.

- Module-Level Monitoring: Enhances O&M efficiency via real-time diagnostics at the panel level.

- Scalability & Flexibility: Easy expansion for both residential and commercial projects.

- Safety (NEC 690.12): Rapid shutdown capability—compliant with U.S. and EU grid codes.

- Superior Performance: Up to 10%-15% yield improvement in shaded or mismatched conditions.

Core industries leveraging ac micro inverter solutions:

- Petrochemicals: Intrinsically safe, corrosion-resistant, for explosion-proof refineries.

- Metallurgy/Mining: Ruggedized housing for harsh outdoor deployments.

- Water Treatment: IP67/68 protection, supports distributed solar for pump systems.

- Data Centers & Telecom: Uninterrupted power backup, remote diagnostics.

- Residential & C&I: Fast payback via modular, low-maintenance architecture.

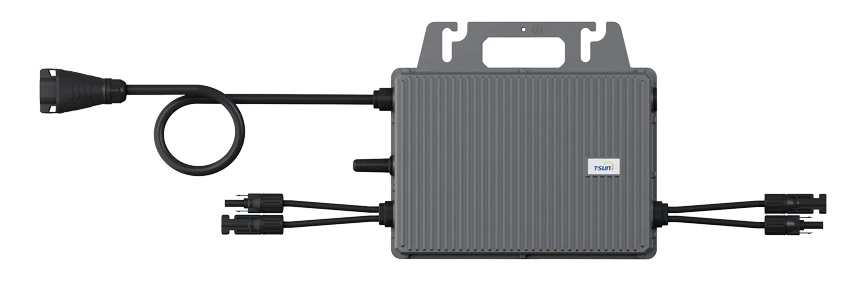

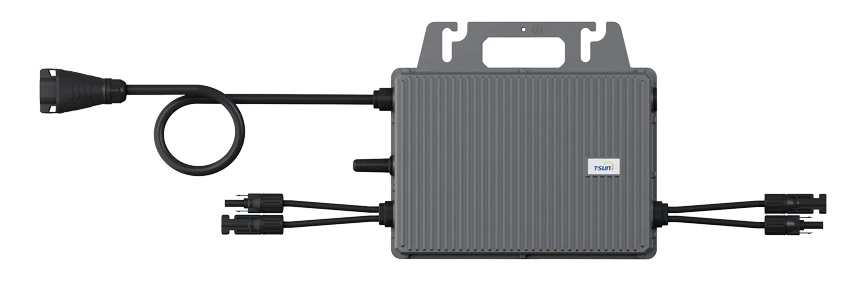

2-in-1 Microinverter – Product Introduction

2-in-1 Microinverter is an advanced ac micro inverter unit designed to serve two PV modules per device. Combining double MPPT channels, robust industrial-grade construction, and global grid standard compliance (ISO 9001, IEC 62109-1/2, CE, VDE4105), it delivers top-tier energy yield and reliability in every deployment.

Product website: 2-in-1 Microinverter – Full Specs & Inquiry

Key Technical Data (2-in-1 Microinverter)

| Parameter |

Specification |

| DC Input Power (Max) |

800W (2x400W PV) |

| MPPT Voltage Range |

22V - 60V |

| Max. Output Power |

700W AC @230V |

| Efficiency (Euro) |

96.5% |

| Protection Class |

IP67 (Water/Dust Proof) |

| THD (Total Harmonic Distortion) |

<3% |

| Communication |

Zigbee Wireless/PLC |

| Operating Temp Range |

-40°C to +65°C |

| Applicable Module Types |

Mono/Poly/Thin-film |

| Certifications |

ISO 9001, IEC, CE, VDE, CSA |

Manufacturing Process Flow (with Diagram): How AC Micro Inverters Are Built

Manufacturing Flowchart (2-in-1 Microinverter)

Aluminum Heat Sink Casting

• Thermal management base

• Anti-corrosion alloy (Al Si12)

→

CNC Machining

• Precision slots & holes

• Mill finish, deburring

→

PCB Assembly (SMT)

• Soldering DSP, FETs

• Conformal coating

→

Enclosure Molding

• Polycarbonate/ABS shell

• Sealing for IP67/IP68

→

Automated Testing

• Hi-Pot, THD, and efficiency tests

• Grid simulation

→

Burn-in & Final QC

• Environmental chamber

• Life-cycle validation

→

Packaging & Traceability

• QR/barcode tagging

• Recyclable EPE foam

Diagram Legend: Critical stages include metal alloy heat sink casting (Aluminum: corrosion-resistance, rapid heat dissipation, key for lifespan & safety), precision CNC for housing, PCB & power electronics mounting for optimum MPPT control, and end-to-end automated safety and performance testing using ISO/IEC 17025 certified labs. Each unit is traceable to batch, and compliant with ISO 9001 / VDE / ANSI C62.41.

Product Specifications Comparison Table: AC Micro Inverters Market

| Model |

Channels |

Max Output (W) |

Efficiency (%) |

Protection Grade |

MPPT Range (V) |

Certifications |

Communication |

| 2-in-1 Microinverter |

2 |

700 |

96.5 |

IP67 |

22-60 |

IEC/CE/VDE/CSA |

Zigbee/PLC |

| Enphase IQ7A |

1 |

366 |

96.5 |

IP67 |

18-58 |

UL/CSA/CE |

2.4GHz/Wi-Fi |

| Apsystems DS3 |

2 |

880 |

96.0 |

IP67 |

16-60 |

CE/VDE/CSA |

2.4GHz/WiFi |

| Hoymiles HMS-800 |

2 |

800 |

96.7 |

IP67 |

16-60 |

IEC/CE/VDE |

2.4GHz/WiFi |

Data Visualization

Output Power Comparison (W)

Protection Standard Distribution in Market (%)

Market Adoption – AC Micro Inverter Types

(2019~2024, Million Units)

Manufacturing Excellence: Material & Process Insight

-

Materials: Aluminum alloy heat sinks (AlSi12), industrial-grade polycarbonate (PC) and ABS housing for anti-UV, weatherproof, and corrosion-resistant body (ISO 9227 certified).

-

Processes: High-pressure die-casting (heat sink), CNC machining for tolerance (

-

Testing: All units undergo 100% hi-pot, over-current, and harmonics/EMC QC, compliant with ANSI, IEC 61000-6-2/4, and IEEE 1547.

-

Longevity: >25-year projected design life, NTC-verified MTBF up to 500,000 hours.

-

Lifespan-validation: Salt spray (ISO 9227), UV exposure (ASTM G154), vibration/shock (IEC 60068).

Solution Customization: Micro Inverter Solar Kit & System Design

Micro inverter solar kit configuration allows for tailored layouts to customer site conditions—supporting various panel orientations, voltages, and grid codes. 2-in-1 Microinverter can be paired up to 14 units (28 modules) per residential circuit or scaled via trunk cabling for commercial systems.

-

OEM/ODM Available: Programmable firmware (MPPT, real-time auto-shutdown, etc.), custom grid-connect (Asia/Europe/America), and housing color/logo optionality.

-

Integration Compatibility: Compatible with leading module brands: Jinko, LONGi, Trina, Canadian Solar, etc.

-

Remote Monitoring: Integrated Zigbee gateway for Smart Home/EMS, REST API for third-party integration.

-

Delivery Cycle: 5 to 7 weeks for standard units, plus 2-3 weeks for advance customization.

-

Support: Online commissioning, on-site technical training, and 10-year standard warranty (extendable to 25 years).

Case Studies: AC Micro Inverter Application Scenarios

-

Chemical Manufacturing Plant (Germany): 2-in-1 microinverters deployed to power electrostatic exhausters on rooftop, withstanding continuous H2S exposure (>1200 hours) per ISO 6988, maintaining THD <3%. Yield improvement: +13% versus string inverter system.

-

Metal Processing Mill (USA): Harsh, 24/7 operation and frequent shading; ac micro inverter enabled maintenance-free operation, and remote panel-level failure tracking—reducing downtime by 87% over two annual cycles.

-

Smart Residential Area (Japan): Tenants configured as micro-grids with micro inverter system (peer-to-peer net metering), grid safety secured by auto rapid-shutdown (NEC 2020).

-

Municipal Water Works (Australia): Outbuilding pumping stations installed solar cell micro inverters in salt-spray, high-humidity zones. IP67 maintained all-year round; system payback within 3.6 years.

“Switching to an AC micro inverter fleet gave us not only higher yield but zero lost-time incidents across two consecutive years—a game-changer for plant operations.” – Facility Manager, Chemical Plant, NRW, Germany

Professional FAQ (AC Micro Inverter Technical FAQ)

Q1: What is the material composition of the primary enclosure and its industry advantage?

A: The enclosure is constructed from high-impact polycarbonate and ABS alloy, tested per ISO 9227. This ensures high UV resistance, anti-corrosion in chemical and marine exposures (third-party salt spray test: >1200 hours), and superior mechanical impact tolerance.

Q2: What is the typical specification for MPPT range and why is it important?

A: For ac micro inverter systems like 2-in-1 Microinverter, MPPT operating voltage is typically 22-60V DC. This allows stable and efficient tracking under partial shading, mismatch, or temperature variations, greatly improving harvested energy, especially on rooftops with variable orientation.

Q3: Which certifications are crucial for global deployment?

A: Key certifications include ISO 9001 (Quality), IEC 62109-1/2 (Safety), CE/VDE (EU grid compliance), UL/CSA (North America), and ANSI/IEEE 1547 (grid interconnect). All units must pass EMC, THD, and grid anti-islanding tests.

Q4: How is communication typically implemented?

A: Leading microinverters, including 2-in-1, offer Zigbee or PLC (Power Line Communication) for panel-level monitoring and firmware updates. This allows integration with third-party EMS, SCADA, and remote cloud analytics.

Q5: What installation standards must be followed on-site?

A: Installers should adhere to NEC 690 (US), VDE 4105 (EU), and AS/NZS 5033 (Australia). This covers mounting, wiring, surge protection, and ensuring safe physical separation of DC and AC runs in micro inverter solar kit deployments. Rapid shutdown compliance (NEC 690.12) is essential for rooftop systems.

Q6: What are the main performance differences between micro inverter and string inverter systems?

A: AC micro inverters optimize each panel independently, eliminate mismatch loss, provide higher yield in shaded or partially soiled conditions, and allow for granular fault diagnosis. String inverters aggregate losses and have longer MTTR (Mean Time To Repair) due to their centralized design.

Q7: What is the warranty and support policy for 2-in-1 Microinverter?

A: Industry-leading standard warranty is 10 years, extendable to 25 years. Comprehensive support includes online/offline diagnostics, 3-day turnaround on advanced RMAs, and priority on-site response for critical infrastructure clients.

Order, Delivery, and Customer Service Commitment

-

Order Cycle: Typical lead time: 5-7 weeks standard, custom requests +2~3 weeks.

-

Warranty: Industry-wide leading coverage: 10 years (extendable 25 years), direct replacement or repair policy.

-

Support: 24/7 hotline, multilingual technical team, remote onboarding, and API documentation for integrators/utility.

For full project quotations, BOM drawing, or a live product demonstration, visit:

AC Micro Inverter – 2-in-1 Product Page

References and Further Reading:

-

IEA PVPS (2024). "Trends in Photovoltaic Applications" (source)

-

IEEE Journal of Photovoltaics, Vol. 13, No. 2, March 2024. "A Review on Panel-level MPPT Algorithms and Reliability" (source)

-

PV-Tech. "Microinverter technologies in global C&I segment" (source)

-

Solar Power World Forum, Technical FAQ. "Microinverter standard evolution & safety" (source)

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE