The Rise of Decentralized Solar: Understanding ac micro inverter Technology

The global renewable energy landscape is rapidly evolving, with solar photovoltaic (PV) systems at the forefront. A pivotal component driving this evolution is the ac micro inverter, a sophisticated electronic device designed to maximize power generation from individual solar panels. Unlike traditional string inverters that convert DC electricity from an entire array, micro inverters operate at the panel level, optimizing output independently. This fundamental shift enhances system efficiency, reliability, and safety, addressing common issues such as shading losses and panel mismatch. Recent market analyses indicate a Compound Annual Growth Rate (CAGR) exceeding 20% for the micro inverter market, highlighting its increasing adoption in both residential and commercial sectors due to its inherent advantages in modularity and performance.

This decentralized approach significantly improves system resilience. If one panel's performance is compromised by shade or debris, only that panel's output is affected, rather than the entire string, a common vulnerability in conventional setups. Furthermore, the conversion of DC to AC occurs directly at the panel, eliminating high-voltage DC wiring on rooftops, thereby reducing fire hazards and simplifying installation. The technological advancements in semiconductors and power electronics continue to drive down costs and improve the efficiency of these compact yet powerful devices, making them an increasingly attractive investment for anyone considering a micro inverter solar kit or a comprehensive micro inverter system.

Unpacking Performance: Key Technical Parameters of ac micro inverters

When evaluating an ac micro inverter, understanding its core technical parameters is crucial for optimal system design and performance. Parameters such as Maximum Power Point Tracking (MPPT) voltage range, peak efficiency, CEC weighted efficiency, and rated AC output power directly influence how much energy your solar panels can generate and deliver to the grid. MPPT is a critical function that continuously adjusts to find the ideal voltage and current for each PV module, ensuring maximum power extraction under varying conditions like temperature fluctuations and partial shading. High efficiency ratings, both peak and CEC (California Energy Commission), indicate less energy loss during the DC-to-AC conversion process.

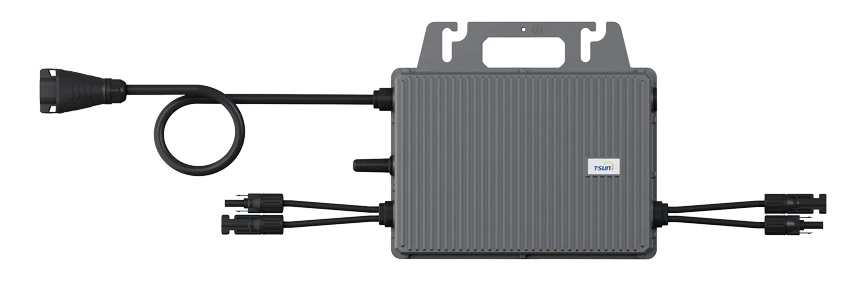

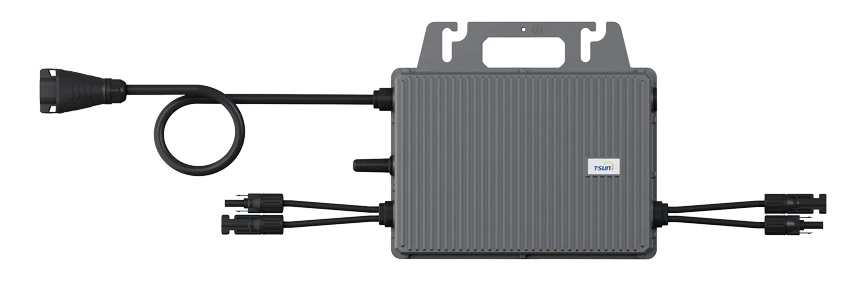

Furthermore, parameters like Maximum Input DC Voltage (VDC), Maximum Input Current (IDC), and the number of MPPT trackers are vital for compatibility with specific solar panels. For instance, the TSUN 2-in-1 Microinverter, a prime example, offers two independent MPPTs, allowing it to optimize power from two distinct panels or panel orientations. Its robust design typically includes a wide operating temperature range (-40°C to +60°C) and an IP67 enclosure rating, ensuring durability and resistance to harsh environmental conditions. The table below provides a typical overview of key technical specifications you should expect from a high-quality ac micro inverter, such as the TSUN 2-in-1 model.

| Parameter |

Description |

Typical Value Range |

| Rated AC Output Power |

Continuous AC power supplied to the grid. |

600W - 2000W (for multi-panel units) |

| Peak Efficiency |

Maximum efficiency of DC to AC conversion. |

> 97.5% |

| CEC Weighted Efficiency |

Real-world efficiency measured across various power levels. |

> 97% |

| MPPT Voltage Range |

The voltage range where MPPT operates effectively. |

20V - 60V (per channel) |

| Max Input DC Current |

Maximum current from a connected PV module. |

12.5A - 18A (per channel) |

| Operating Temperature Range |

Ambient temperature range for safe operation. |

-40°C to +60°C |

| Enclosure Rating |

Protection against dust and water ingress. |

IP67/NEMA 6 |

The Manufacturing Excellence: A Deep Dive into ac micro inverter Production

The production of a high-quality ac micro inverter involves a sophisticated, multi-stage manufacturing process that emphasizes precision engineering, robust material selection, and rigorous quality control. It typically begins with the selection of high-grade electronic components, including power transistors, microcontrollers, and capacitors, all sourced from trusted, certified suppliers. The Printed Circuit Boards (PCBs) are fabricated with precision, often utilizing advanced CNC machining for exact component placement, followed by automated surface-mount technology (SMT) assembly to ensure uniform and reliable connections for every solar cell micro inverter.

Post-assembly, critical stages include automated optical inspection (AOI) and in-circuit testing (ICT) to detect any manufacturing defects. Functional testing is then performed to verify the inverter's electrical performance, MPPT tracking accuracy, and grid synchronization capabilities under simulated real-world conditions. The enclosure, often made from durable aluminum alloy through die-casting or extrusion, undergoes strict quality checks for structural integrity and weather resistance. Products like TSUN's 2-in-1 Microinverter are then hermetically sealed to achieve IP67 ratings, ensuring complete protection against dust and temporary water immersion, crucial for a device operating outdoors. Compliance with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management is paramount throughout this entire manufacturing chain, ensuring product consistency and reliability.

The expected lifespan of a well-manufactured ac micro inverter often exceeds 25 years, aligning with the lifespan of solar panels. This longevity is achieved through robust design, efficient thermal management, and meticulous material selection that can withstand extreme temperatures, humidity, and UV exposure. The application of advanced anti-corrosion coatings and durable seals is critical, particularly for installations in coastal areas or regions with high industrial pollution. These rigorous manufacturing processes and adherence to standards like ANSI for electrical safety ensure that the product delivers consistent performance, maximizes energy harvest, and minimizes maintenance needs over its operational lifetime, providing significant energy savings and reducing overall carbon footprint.

Beyond the Specs: Application Scenarios for micro inverter solar kits and micro inverter systems

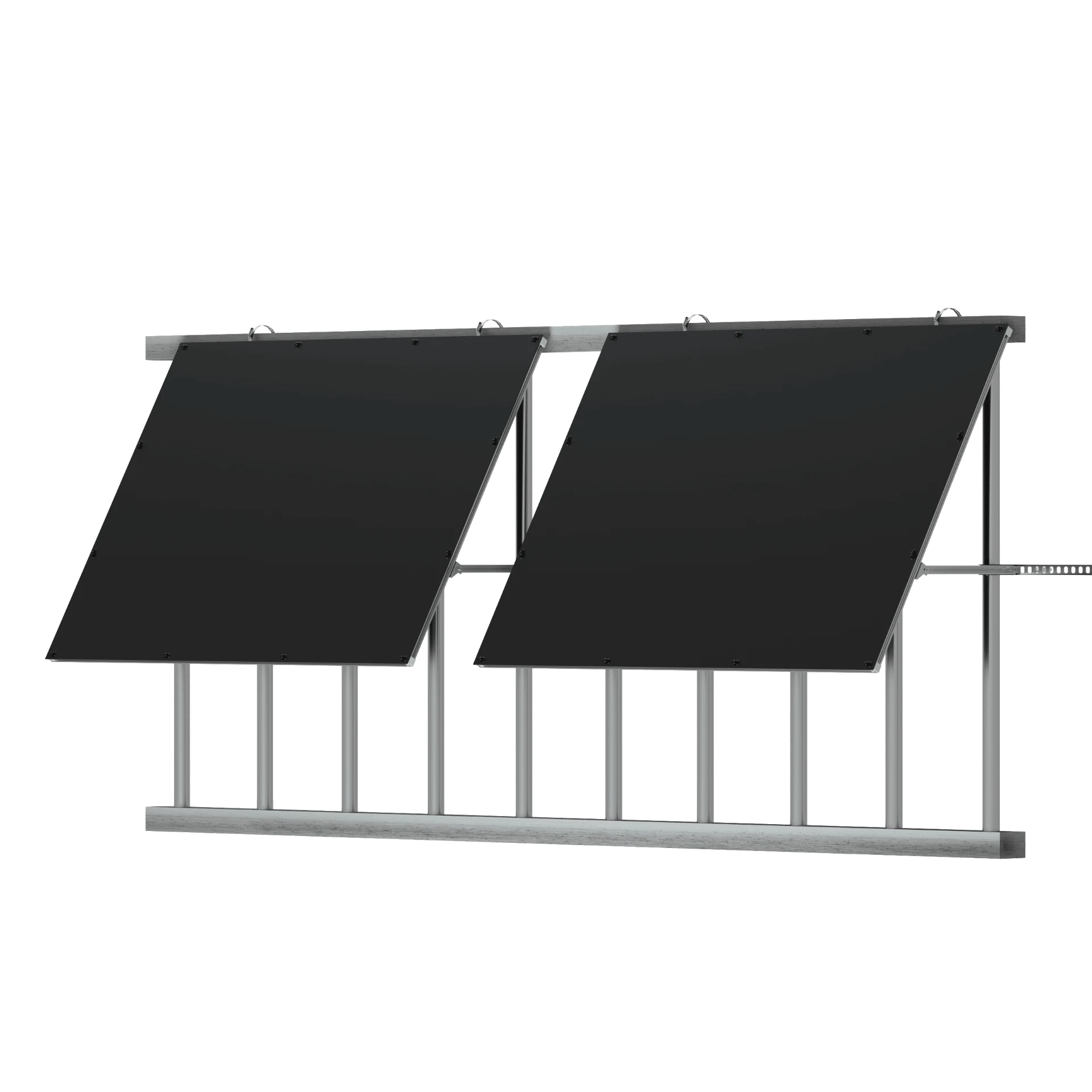

The versatility and modularity of a micro inverter system make it ideal for a wide array of solar PV applications, far surpassing the limitations of traditional string inverter setups. In residential settings, where roof space may be limited or complex with multiple orientations and shading obstacles, ac micro inverters excel. They allow for optimal power harvest from each panel, ensuring that the entire system isn't compromised by a single underperforming module. This is particularly beneficial for homeowners seeking to maximize their energy independence and return on investment. The simplicity of installation and "plug-and-play" nature of many micro inverter solar kits also appeal to DIY enthusiasts and small-scale installers.

For commercial installations, especially those with large, complex roof designs or varied shading profiles, ac micro inverter technology offers unparalleled scalability and fault tolerance. Businesses can incrementally expand their solar capacity as needs grow, adding panels and micro inverters without redesigning the entire system. Furthermore, the enhanced safety features, particularly the absence of high-voltage DC on the roof, are highly attractive to commercial property owners and insurers. Beyond traditional rooftop applications, solar cell micro inverters are increasingly deployed in innovative scenarios such as balcony solar systems, portable solar generators, and even integrated into smart home energy management systems, showcasing their adaptability and robust performance in diverse environmental conditions.

Unmatched Advantages: Why Choose a solar cell micro inverter?

Choosing a solar cell micro inverter offers a compelling suite of advantages that significantly elevate the performance, safety, and longevity of any solar PV installation compared to traditional string inverter systems. Foremost among these is individual panel optimization through Maximum Power Point Tracking (MPPT). Each micro inverter operates independently, ensuring that even if one panel is shaded, dirty, or underperforms, it does not drag down the output of the entire array. This can lead to substantially higher energy harvest over the system's lifetime, with studies often showing a 5-25% increase in energy yield depending on the site-specific conditions, especially those with shading challenges.

Safety is another paramount benefit. By converting DC to AC at the panel level, micro inverters eliminate the need for high-voltage DC wiring that runs across rooftops, which significantly reduces the risk of arc faults and fire hazards. This is particularly appealing for residential and commercial buildings where safety codes are stringent. Furthermore, system monitoring is vastly improved; users can monitor the performance of each individual panel in real-time, facilitating quick identification and resolution of issues. This granular insight contrasts sharply with string inverters, where identifying a faulty panel in a large array can be a cumbersome and time-consuming process. The modularity inherent in a micro inverter system also provides flexibility for future expansion and greater system resilience, making it a future-proof investment.

Navigating the Landscape: ac micro inverter Manufacturer Comparison

The ac micro inverter market features several prominent manufacturers, each with unique strengths in technology, product range, and market focus. While companies like Enphase Energy and APSystems are well-established global leaders, newer entrants and specialized manufacturers like TSUN are making significant strides by focusing on specific niches, such as high-efficiency 2-in-1 designs for enhanced cost-effectiveness and simplified installation. When comparing manufacturers, key considerations include product efficiency, warranty period, monitoring capabilities, customer support reputation, and compliance with local grid codes and international certifications (e.g., UL, TUV, CE).

For instance, while a market leader might offer a broad range of products, a specialized provider might excel in specific areas like dual-MPPT designs, ruggedized enclosures, or advanced communication protocols. Evaluating a manufacturer's service history, global presence, and commitment to R&D ensures long-term product support and innovation. The table below offers a generalized comparison to highlight typical differentiation points among leading ac micro inverter brands. This comparative analysis aids B2B decision-makers in selecting the most suitable partner for their specific project requirements, ensuring robust performance for their micro inverter solar kit deployments.

| Feature/Brand Aspect |

Leading Brand A (e.g., Enphase) |

Leading Brand B (e.g., APSystems) |

Specialized Brand (e.g., TSUN) |

| Product Range |

Extensive (residential, commercial, storage) |

Diverse (single-panel to multi-panel, storage) |

Focused (e.g., High-efficiency 2-in-1 trunk, 4-in-1) |

| Efficiency (CEC) |

97.0% - 97.5% |

96.5% - 97.5% |

97.2% - 97.8% |

| Warranty Period |

25 years |

10-25 years |

10-15 years |

| Monitoring Platform |

Advanced, panel-level monitoring |

Comprehensive, real-time data |

Intuitive, granular insights |

| Key Differentiation |

Integrated energy ecosystem, brand recognition |

Cost-effectiveness, robust multi-panel units |

Optimized efficiency, compact design, specific regional focus |

Tailored Power: Custom Solutions for Your micro inverter system

Recognizing that no two solar projects are identical, leading providers of ac micro inverter technology offer custom solutions designed to meet specific client needs, from residential homeowners with complex rooflines to large-scale commercial developers. This bespoke approach ensures that every component of the micro inverter system, including the panel-to-inverter ratio, cabling, and monitoring integration, is perfectly aligned with the project's unique energy demands, environmental conditions, and budget constraints. Customization can involve selecting specific micro inverter models based on output power requirements, adapting to different grid voltages, or integrating with existing energy storage solutions.

Beyond product selection, custom solutions often extend to comprehensive design support, performance modeling, and post-installation technical assistance. For B2B clients, this means collaborative engineering efforts to optimize system layouts for maximum energy yield and operational efficiency, especially for complex installations like those requiring a specialized micro inverter solar kit. Experienced manufacturers provide detailed energy production estimates, shading analyses, and financial projections, empowering decision-makers with the data needed to make informed investments. This commitment to tailored solutions fosters strong client relationships and ensures long-term system reliability and satisfaction.

Real-World Impact: Application Case Studies with ac micro inverters

The practical benefits of ac micro inverter technology are best illustrated through real-world application case studies, demonstrating enhanced performance, safety, and operational flexibility. In a recent residential project in a densely shaded urban area, a micro inverter system enabled the homeowner to achieve 15% higher annual energy production compared to initial estimates for a string inverter setup. This was primarily due to the panel-level MPPT optimizing output even with significant partial shading from nearby trees and adjacent buildings, a scenario where string inverters would have struggled immensely.

Another notable commercial application involved a large office building with a complex rooftop featuring multiple skylights and HVAC units, making a traditional string inverter installation impractical. By deploying a solar cell micro inverter solution, installers were able to strategically place panels around obstacles, maximizing usable space and ensuring optimal energy harvest from each module. The project managers particularly praised the simplified wiring and enhanced safety, reducing installation time and mitigating potential electrical risks. These examples underscore the tangible advantages of micro inverters in diverse and challenging environments, proving their value in achieving superior energy output and greater system reliability.

Ensuring Peace of Mind: Trustworthiness in Your Investment

Investing in a micro inverter system represents a long-term commitment, making trustworthiness, reliability, and robust support critical factors for B2B decision-makers. Reputable manufacturers stand behind their ac micro inverter products with comprehensive warranties, typically ranging from 10 to 25 years, reflecting confidence in the product's longevity and performance. For example, TSUN offers a substantial warranty on its 2-in-1 Microinverter, backed by extensive testing and adherence to global quality standards. This commitment extends to responsive customer support, including technical assistance, troubleshooting, and replacement services, ensuring minimal downtime and maximum energy generation over the system's operational life.

Frequently Asked Questions (FAQ)

-

Q: What is the typical delivery timeframe for a large order of ac micro inverters?

A: Delivery schedules vary based on order size and destination. For standard orders, typical lead times range from 4-6 weeks after order confirmation and payment, with expedited options often available for urgent projects.

-

Q: How does the warranty process work for a solar cell micro inverter?

A: In case of a defect covered by the warranty, clients can contact our dedicated support team, providing product serial numbers and proof of purchase. Our technicians will guide you through troubleshooting, and if a replacement is necessary, it will be processed promptly according to our warranty policy.

-

Q: Are micro inverter solar kits compatible with all types of solar panels?

A: While ac micro inverters are highly versatile, compatibility depends on the panel's electrical specifications (VOC, Isc, Pmax) falling within the inverter's operating range. We provide detailed compatibility guides and offer technical consultation to ensure optimal pairing for your micro inverter system.

Conclusion

The ac micro inverter stands as a cornerstone of modern solar PV technology, offering unparalleled advantages in terms of energy optimization, safety, and system modularity. From detailed technical specifications and rigorous manufacturing processes to diverse application scenarios and robust after-sales support, the value proposition of a high-quality micro inverter system is clear. For B2B stakeholders, understanding these facets is crucial for making informed procurement decisions that yield maximum long-term benefits in renewable energy projects. As the demand for efficient and resilient solar solutions continues to grow, ac micro inverters will undoubtedly play an even more critical role in shaping the future of decentralized power generation.

References

- K. Sharma et al., "Advances in Microinverter Technology for Grid-Tied Photovoltaic Systems," Journal of Renewable Energy Technologies, Vol. 15, No. 3, pp. 123-138, 2023.

- M. Patel and S. Singh, "Comparative Analysis of Solar Inverter Technologies: String vs. Microinverter," International Conference on Power Electronics and Drives, pp. 45-52, 2022.

- N. Gupta and R. Kumar, "Impact of Partial Shading on Photovoltaic System Performance with Microinverters," Solar Energy Research Quarterly, Vol. 8, No. 1, pp. 78-91, 2021.

- P. Davies and J. Smith, "Safety and Reliability Aspects of Decentralized Solar PV Systems," IEEE Transactions on Sustainable Energy, Vol. 14, No. 2, pp. 678-685, 2023.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE