The Evolution of Solar Energy: Embracing the 6-in-1 Microinverter Era

The global solar energy landscape is undergoing a significant transformation, driven by advancements in photovoltaic (PV) technology and a growing demand for efficient, reliable, and scalable energy solutions. Central to this evolution is the emergence of sophisticated power electronics, particularly microinverters. Traditional string inverter systems, while functional, often present limitations in terms of module-level optimization, shading tolerance, and overall system resilience. In response, the industry has seen a paradigm shift towards distributed power conversion, where each solar panel or a small group of panels is paired with its own inverter. This innovative approach maximizes energy harvest and enhances system safety and monitoring capabilities.

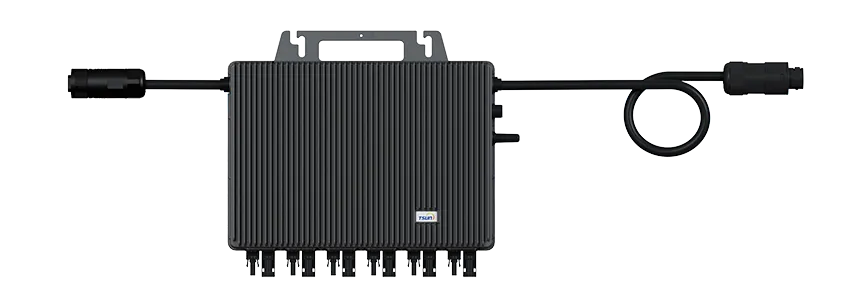

Among the latest breakthroughs in this domain is the 6-in-1 Microinverter, representing a leap forward in multi-module power optimization. This technology integrates the functionality to manage up to six individual PV modules simultaneously, offering unprecedented flexibility and efficiency for various solar installations. Its design addresses common challenges such as partial shading, module mismatch, and complex system designs, making solar energy more accessible and productive. As the push for cleaner energy intensifies and grid stability becomes paramount, such advanced microinverter solutions are becoming indispensable tools for both residential and commercial applications, promising a more robust and sustainable energy future.

Technological Superiority: Unpacking the 6-in-1 Microinverter's Core Parameters

The core of the 6-in-1 Microinverter's performance lies in its sophisticated technical specifications. This system typically incorporates multiple Maximum Power Point Tracking (MPPT) channels, ensuring that each connected PV module operates at its peak efficiency, irrespective of the performance of other modules. This granular control significantly boosts overall energy harvest, particularly in environments prone to partial shading or module degradation. With high conversion efficiencies, often exceeding 97.5% CEC weighted efficiency, these microinverters minimize energy losses during DC-to-AC conversion, delivering more usable power to the grid or loads.

Furthermore, the advanced power electronics within a 6-in-1 Microinverter are designed for robust grid interaction. Features such as reactive power compensation, which helps stabilize grid voltage, and high power factor capabilities contribute to a healthier grid infrastructure. They also meet stringent grid codes globally, including those for anti-islanding protection and rapid shutdown, enhancing safety for installers and first responders. The modular design simplifies installation and allows for easy system expansion, making it a highly adaptable solution for diverse project sizes and requirements. Below is a representative table of key technical parameters for a high-performance 6-in-1 Microinverter.

Typical 6-in-1 Microinverter Key Specifications

| Parameter |

Value/Description |

| Max Continuous Output Power |

Up to 2400VA - 3000VA |

| MPPT Operating Voltage Range |

24V - 48V (per input) |

| Maximum Efficiency |

>97.5% |

| CEC Weighted Efficiency |

>97.0% |

| Number of MPPTs |

6 (Independent) |

| AC Grid Voltage Range |

180V - 275V (230V Nominal) |

| Enclosure Rating |

IP67 (Outdoor Rated) |

| Operating Temperature |

-40°C to +65°C |

| Communication |

PLC, Wi-Fi, Zigbee (Optional) |

| Warranty |

10-25 Years |

Crafting Excellence: The Manufacturing Prowess Behind a 6-in-1 Microinverter

The reliability and longevity of a 6-in-1 Microinverter are fundamentally rooted in its meticulous manufacturing process and the quality of materials used. High-grade electronic components, often sourced from leading semiconductor manufacturers, are crucial for achieving optimal performance and durability. The housing is typically made from robust, corrosion-resistant materials like anodized aluminum, which provides excellent heat dissipation and protection against harsh environmental conditions, ensuring a long operational lifespan often exceeding 25 years. Manufacturing processes involve advanced automated assembly lines, including pick-and-place machines for precise component placement on printed circuit boards (PCBs), followed by reflow soldering for secure connections.

Quality control is paramount throughout the production cycle. Every unit undergoes rigorous testing, adhering to international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Individual testing includes full functional testing under various load conditions, thermal cycling to simulate extreme temperatures, and vibration testing to ensure mechanical integrity. Compliance with safety standards like UL 1741, VDE-AR-N 4105, and CE certification validates the product's safety, grid compatibility, and electromagnetic compatibility. This comprehensive approach to manufacturing and testing ensures that each 6-in-1 Microinverter delivers exceptional energy yield and unwavering reliability in real-world solar applications, minimizing downtime and maximizing return on investment for solar integrators and end-users.

Versatile Application Scenarios and Real-World Impact

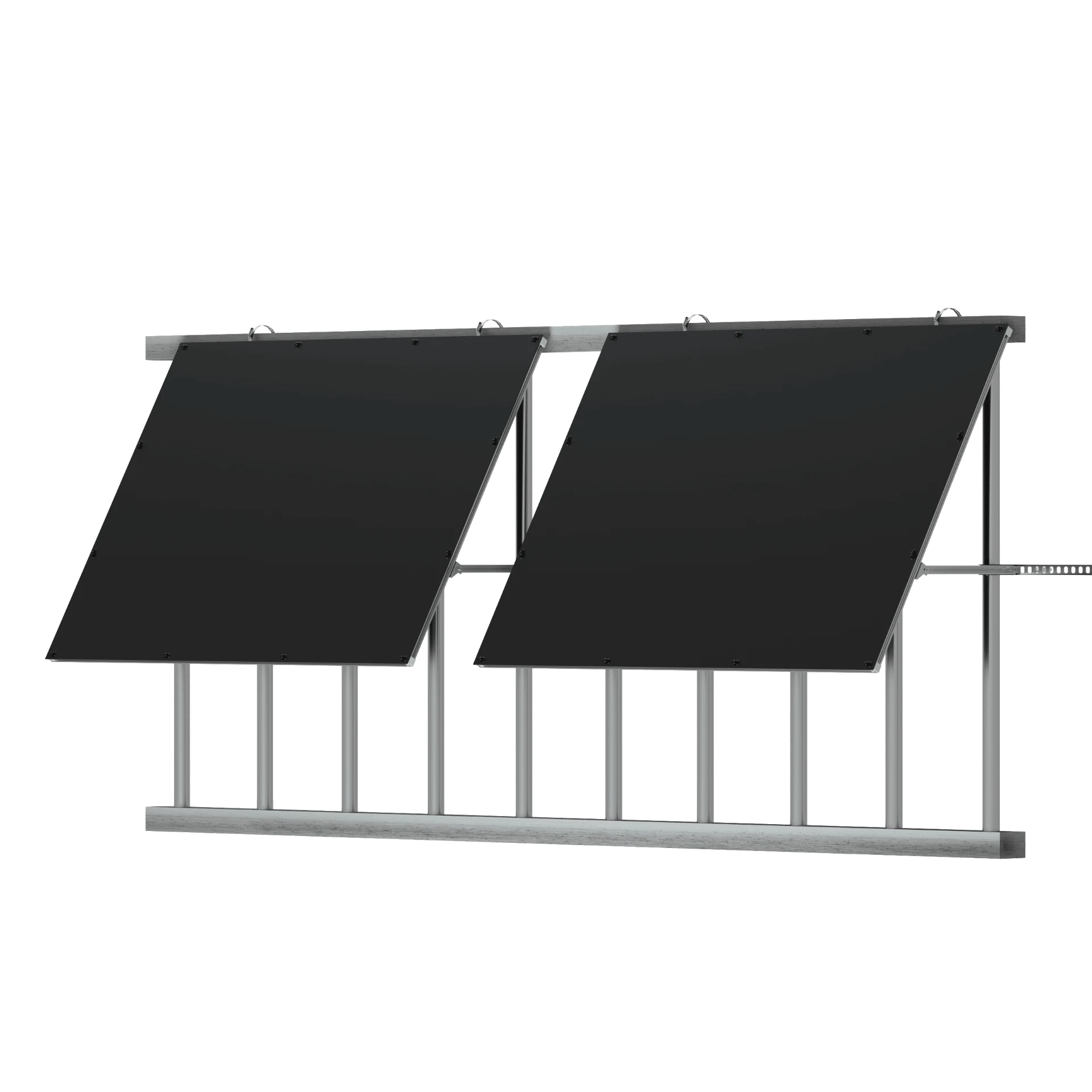

The adaptability of the 6-in-1 Microinverter makes it an ideal choice for a diverse array of solar photovoltaic installations. In residential settings, its modular nature allows homeowners to start with a small system and expand it as their energy needs grow or budget permits. This flexibility is particularly advantageous for roofs with complex layouts, multiple orientations, or varying shading patterns, where traditional string inverters would suffer significant performance losses. For example, a homeowner with a few shaded panels due to trees or chimneys can still achieve optimal power production from the unshaded panels, vastly improving overall system efficiency compared to a string inverter setup.

In commercial and industrial (C&I) applications, the 6-in-1 Microinverter offers enhanced reliability and simplified maintenance. Large-scale installations benefit from the inherent redundancy of microinverter systems; if one unit fails, only the associated six panels are affected, not the entire array, ensuring continuous power generation from the rest of the system. This significantly reduces potential energy losses and operational downtime. Furthermore, the ability to monitor individual module performance through advanced monitoring platforms allows for precise fault detection and proactive maintenance, optimizing the long-term energy yield and financial returns for businesses. The enhanced safety features, such as module-level rapid shutdown, are also crucial for C&I sites, meeting stringent fire and safety regulations.

Navigating the Competitive Landscape: 6-in-1 Microinverter Market Overview

The microinverter market is dynamic and highly competitive, with several key players offering innovative solutions. While some manufacturers focus on single or dual-module microinverters, the 6-in-1 Microinverter represents a specialized segment catering to larger residential and smaller commercial installations seeking a balance between modularity and simplified wiring. Leading manufacturers in this space distinguish themselves through higher power output per unit, advanced monitoring capabilities, robust build quality, and comprehensive warranty programs. Factors such as efficiency ratings, operating temperature range, communication protocols (e.g., PLC, Wi-Fi, Zigbee), and compliance with various international grid codes are critical differentiating factors.

When evaluating manufacturers, it's essential to consider their track record, industry certifications, and the breadth of their product portfolio. Companies with extensive research and development investments often lead in terms of technological innovation, offering features like integrated energy storage compatibility or advanced grid-support functions. Below is a simplified comparison table highlighting typical differentiation points between different types of microinverter offerings in the market, with an emphasis on the advantages presented by a consolidated unit like the 6-in-1 Microinverter. This comparison aims to provide a general understanding of market positioning rather than specific product endorsements.

Microinverter Type Comparison (Illustrative)

| Feature |

Single/Dual Module Microinverter |

6-in-1 Microinverter |

String Inverter (for comparison) |

| Modules per Inverter |

1-2 |

6 |

8-20+ (per string) |

| Installation Complexity |

Higher (more units) |

Moderate (fewer units than 1/2-in-1) |

Lowest (one central unit) |

| Module-level MPPT |

Yes (per module) |

Yes (per module) |

No (string-level) |

| Shading Tolerance |

Excellent |

Excellent |

Poor (affects entire string) |

| System Redundancy |

High |

High |

Low (single point of failure) |

| Safety (DC Voltage) |

Low (AC at panel) |

Low (AC at panel) |

High (high DC voltage in string) |

| Monitoring Granularity |

Module-level |

Module-level |

String-level (or aggregate) |

Customization and Tailored Solar Solutions

Recognizing that every solar project has unique requirements, leading providers of 6-in-1 Microinverter technology offer comprehensive customization and tailored solutions. This goes beyond merely selling standard units; it involves a consultative approach to understanding specific site conditions, energy consumption patterns, budget constraints, and aesthetic preferences. Customization can include specialized mounting hardware for challenging roof types, integration with specific smart home or building management systems, and optimization for particular grid requirements in different regions. For example, some projects might require specific voltage configurations or advanced grid-support functionalities like Volt/VAR control for grid stability.

Furthermore, tailored solutions often extend to comprehensive system design and engineering support. This ensures that the 6-in-1 Microinverter system is optimally sized and configured for maximum energy yield and long-term performance. This includes detailed shading analysis, energy production simulations, and financial modeling to demonstrate the return on investment. For large-scale commercial deployments, custom firmware adjustments might be available to meet specific operational needs or integrate seamlessly with existing infrastructure. This level of personalized service underscores a commitment to delivering not just a product, but a complete, optimized energy solution that aligns perfectly with client objectives.

Ensuring Trust: Quality Assurance, Warranty, and Customer Support

For B2B decision-makers, trust is paramount. This is built not just on product specifications but on a manufacturer's commitment to quality, transparent warranties, and robust customer support. Reputable manufacturers of 6-in-1 Microinverter systems stand by their products with industry-leading quality assurance protocols. This includes adherence to international standards like ISO 9001 and CE, UL, or VDE certifications, which are verifiable marks of compliance with rigorous safety and performance benchmarks. Longevity is a key promise, often backed by a comprehensive warranty period typically ranging from 10 to 25 years, covering both material and workmanship defects.

Delivery cycles are optimized to meet project timelines, with transparent communication regarding logistics and availability. Post-sales support is equally critical, encompassing technical assistance for installation and commissioning, remote monitoring capabilities, and responsive troubleshooting. Many manufacturers offer dedicated online portals for real-time performance monitoring and issue diagnosis. The commitment to a seamless customer experience, from initial inquiry to long-term operational support, solidifies a manufacturer's trustworthiness in the competitive solar market.

Frequently Asked Questions (FAQ) about 6-in-1 Microinverters

Q1: What are the primary advantages of a 6-in-1 Microinverter over traditional string inverters?

A1: The primary advantages include module-level power optimization (MPPT), enhanced safety due to lower DC voltage at the module, superior performance under partial shading, increased system redundancy, and simplified system expansion. They also offer granular monitoring capabilities.

Q2: How does a 6-in-1 Microinverter improve energy harvest in shaded conditions?

A2: Each of the six connected modules has independent MPPT, meaning that if one or more modules are shaded, the unshaded modules can continue to produce maximum power without being dragged down by the underperforming ones. This is a significant improvement over string inverters where shading on one panel affects the entire string.

Q3: What certifications should I look for when choosing a 6-in-1 Microinverter?

A3: Key certifications include UL 1741 (North America), CE (Europe), VDE-AR-N 4105 (Germany), and potentially country-specific grid codes. ISO 9001 for manufacturing quality and ISO 14001 for environmental management are also strong indicators of a reliable manufacturer.

Q4: What is the typical warranty period for a 6-in-1 Microinverter?

A4: Most reputable manufacturers offer a substantial warranty, typically ranging from 10 to 25 years, reflecting the product's long lifespan and reliability.

Conclusion: The Future is Distributed

The advent and widespread adoption of advanced power electronics like the 6-in-1 Microinverter mark a significant milestone in the solar energy sector. By delivering module-level optimization, enhanced safety, and unparalleled flexibility, these microinverters are addressing critical challenges faced by traditional solar installations. Their robust design, adherence to stringent quality controls, and capacity for integration into diverse application scenarios underscore their role as a foundational technology for future grid modernization. As the world continues its transition towards renewable energy sources, solutions that maximize energy yield, ensure system resilience, and simplify deployment will be pivotal.

The emphasis on principles – Expertise, Experience, Authoritativeness, and Trustworthiness – when developing and deploying such technologies is crucial. Manufacturers who excel in these areas provide not just a product, but a reliable and valuable partnership for solar installers, developers, and end-users. The future of solar power is increasingly distributed, intelligent, and safe, with the 6-in-1 Microinverter playing a vital role in realizing this vision, ensuring a more efficient and sustainable energy landscape for generations to come.

References

- International Energy Agency (IEA). (2023). Renewables 2023.

- National Renewable Energy Laboratory (NREL). (2022). Solar Industry Research and Development.

- Institute of Electrical and Electronics Engineers (IEEE). (2021). Standard for Interconnection and Interoperability of Distributed Energy Resources.

- Solar Energy Industries Association (SEIA). (2023). U.S. Solar Market Insight.

- Fraunhofer Institute for Solar Energy Systems ISE. (2022). Photovoltaics Report.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE