Navigating the Future of Solar: Industry Trends and the Multi-Channel Microinverter Revolution

The global energy landscape is undergoing a profound transformation, driven by an imperative for sustainable and decentralized power generation. This shift is characterized by an accelerating adoption of renewable energy sources, with solar photovoltaics (PV) leading the charge due to decreasing costs and technological advancements. A key trend emerging is the increasing demand for Distributed Generation (DG) systems, where energy is produced closer to the point of consumption, reducing transmission losses and enhancing grid resilience. Within this paradigm, microinverters have distinguished themselves as a superior alternative to traditional string inverters, offering enhanced module-level power optimization, greater safety, and improved system reliability. The evolution from single or dual-input microinverters to multi-channel solutions represents a significant leap forward, particularly in complex residential and commercial installations. This innovation addresses common challenges such as partial shading, varying module performance, and system expandability, making solar energy more accessible and efficient for a wider range of applications. As the industry matures, the emphasis is shifting towards solutions that provide maximum energy harvest, simplified installations, and robust long-term performance, positioning advanced microinverter technologies at the forefront of this energy transition. The market is increasingly valuing granular control over each PV module, ensuring that system performance is not bottlenecked by the weakest link, thereby maximizing the return on investment for end-users and project developers alike.

Analyzing recent market data, the global microinverter market is projected to grow at a Compound Annual Growth Rate (CAGR) exceeding 20% from 2023 to 2030, driven by policy support, technological innovation, and rising awareness of solar energy benefits. This growth is particularly pronounced in regions with high population density and varied rooftop architectures, where the benefits of module-level optimization are most apparent. Moreover, the increasing integration of energy storage solutions alongside PV systems further amplifies the need for intelligent power electronics that can seamlessly manage energy flow. The introduction of highly integrated solutions like the GEN3 Microinverter 6-in-1 epitomizes this forward trajectory. By consolidating the functionality for up to six solar modules into a single unit, it addresses critical industry demands for streamlined Balance-of-System (BoS) costs, reduced installation complexity, and optimized energy yield across diverse environmental conditions. This innovative design caters to the evolving needs of installers and system owners who seek not only efficiency but also scalability and enhanced fault tolerance. The market trend clearly indicates a preference for solutions that combine high performance with operational simplicity, reinforcing the strategic importance of multi-channel microinverter designs in shaping the next generation of solar deployments.

Unveiling Core Specifications: The GEN3 Microinverter 6-in-1

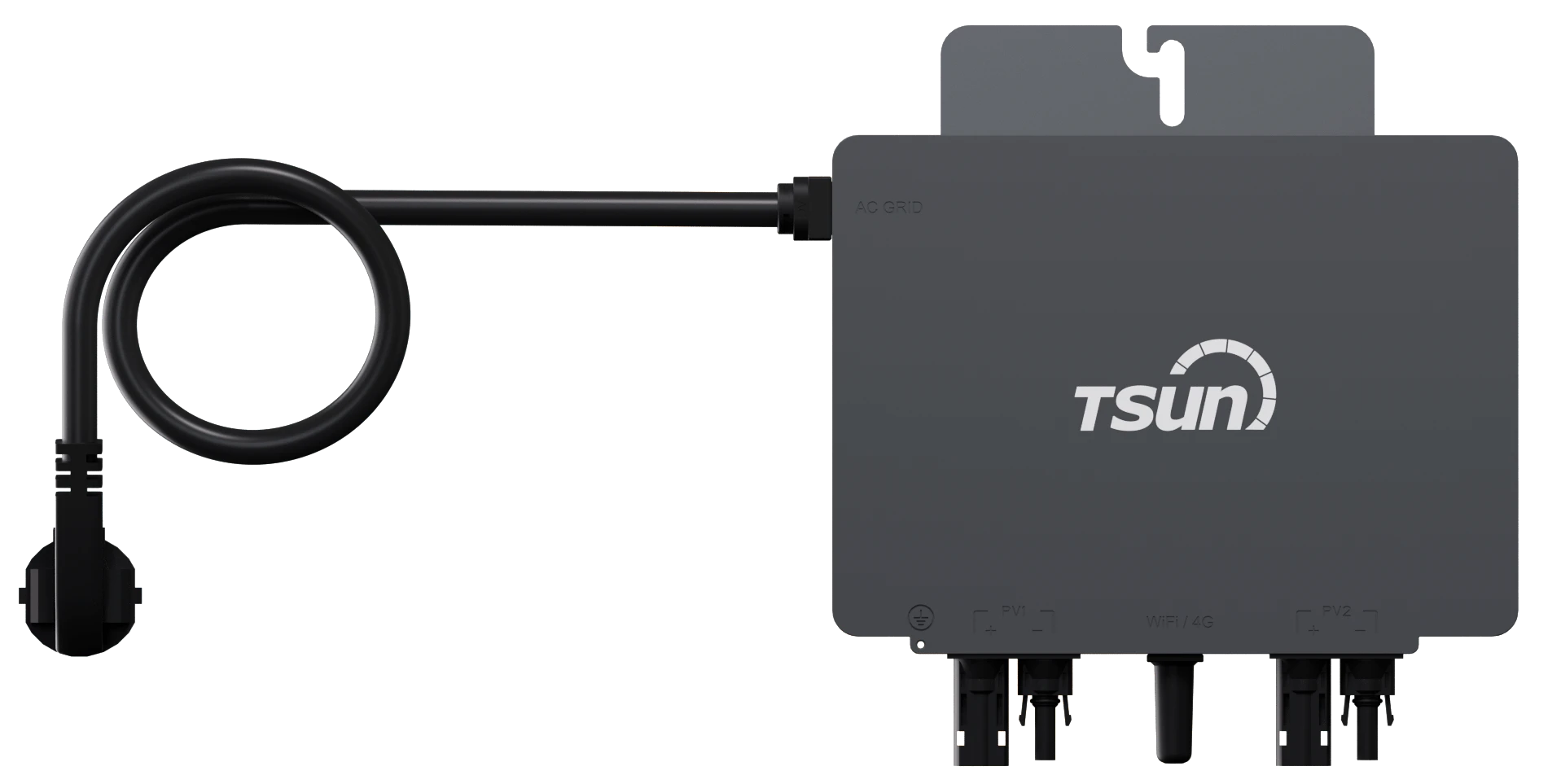

At the heart of any advanced solar power solution lies its technical prowess, and the GEN3 Microinverter 6-in-1 stands as a testament to cutting-edge engineering. This revolutionary device is engineered to maximize energy harvest from up to six individual PV modules, each with independent Maximum Power Point Tracking (MPPT). This architecture ensures that even if one module is partially shaded or performing sub-optimally, the overall system's energy production is not compromised, a critical advantage over traditional string inverter systems. The unit boasts an impressive peak efficiency rating, often exceeding 97.5%, and a CEC weighted efficiency that ensures high real-world performance across various operating conditions. Its wide MPPT voltage range allows compatibility with a broad spectrum of PV modules, including high-power modules now prevalent in the market. Designed for durability, the inverter features an IP67 enclosure, providing superior protection against dust and water ingress, making it suitable for harsh outdoor environments. Safety is paramount, with integrated rapid shutdown capabilities and low DC voltage operation, significantly reducing fire hazards associated with high-voltage DC systems.

The robust design of the GEN3 Microinverter 6-in-1 extends to its communication capabilities, typically supporting PLC (Power Line Communication) or Wi-Fi connectivity for seamless data transmission to monitoring platforms. This allows for granular, real-time performance tracking of each module, enabling proactive maintenance and rapid fault diagnosis. The unit's output power is meticulously designed to align with typical grid connection requirements, ensuring smooth integration into residential and light commercial grids globally. Furthermore, its lightweight and compact form factor simplify installation, reducing labor costs and improving project timelines. The internal components are selected for their longevity and performance under stress, contributing to a projected operational lifespan that matches or exceeds industry standards, often backed by extended warranties. For professional system designers and installers, understanding these detailed specifications is crucial for optimizing system sizing, ensuring grid compliance, and ultimately delivering a high-performing and reliable solar solution to their clients. The meticulous attention to detail in its design and component selection underscores its position as a premium choice for distributed PV applications.

Key Technical Specifications: GEN3 Microinverter 6-in-1

| Parameter |

Value / Description |

| Input DC Connectors |

6 Independent MPPT Inputs |

| Recommended PV Module Power |

Typically 300W - 600W+ per input |

| MPPT Voltage Range |

25V - 60V (optimized for various module types) |

| Max DC Input Current |

14A - 18A per MPPT |

| Rated AC Output Power |

Up to 2400W (e.g., 400W x 6) - Varies by model |

| Peak Efficiency |

≥ 97.5% |

| CEC Weighted Efficiency |

≥ 97.0% |

| Operating Temperature Range |

-40°C to +65°C |

| Enclosure Rating |

IP67 |

| Communication |

PLC / Wi-Fi (built-in or external DTU) |

| Monitoring |

Module-level via dedicated platform |

| Certifications |

UL1741, IEC/EN 62109, AS/NZS 4777, CE, VDE (market dependent) |

Strategic Advantages of the GEN3 Microinverter 6-in-1

The innovative 6-in-1 architecture of the GEN3 Microinverter 6-in-1 confers a multitude of strategic advantages over conventional solar inverter technologies, positioning it as a preferred choice for discerning solar professionals. Foremost among these is the unparalleled module-level optimization. Each of the six PV modules connected to the microinverter operates independently, managed by its own MPPT algorithm. This granular control means that issues like partial shading, module degradation, or soiling on a single panel will not adversely affect the performance of the entire array. In contrast, string inverters, and even microinverters with fewer input channels, suffer from the "Christmas light effect" where the weakest module dictates the performance of the entire string or group, leading to significant energy harvest losses. Our 6-in-1 design ensures maximum power extraction from every single module, leading to up to 25% higher energy yield over the system's lifetime compared to string inverter systems, especially in environments prone to varying conditions.

Beyond efficiency, the GEN3 Microinverter 6-in-1 offers substantial benefits in terms of system reliability, safety, and operational expenditure (OpEx). By distributing power conversion across multiple independent units, the system avoids a single point of failure that is inherent in string inverter designs; should one microinverter fail, only a small portion of the array's output is affected, rather than the entire system. This enhances system uptime and reduces potential revenue loss. From a safety perspective, microinverters operate with low DC voltages at the module level, significantly mitigating arc fault risks and complying with stringent rapid shutdown requirements (e.g., NEC 2017/2020), which is critical for fire safety in residential and commercial buildings. Installation is also vastly simplified. With fewer units to install compared to one-to-one microinverter solutions, and no need for complex string sizing or DC conduit runs, Balance-of-System (BoS) costs are substantially reduced. This translates to lower labor costs, quicker deployment times, and a more streamlined project workflow for installers. The modularity also allows for easy system expansion, enabling future additions without a complete system overhaul. These combined advantages make the GEN3 Microinverter 6-in-1 a compelling choice for solar professionals seeking optimal performance, safety, and long-term value.

Precision Engineering: The Manufacturing Process of GEN3 Microinverter 6-in-1

The superior performance and reliability of the GEN3 Microinverter 6-in-1 are a direct result of a meticulously engineered manufacturing process, emphasizing precision, quality control, and robust component selection. Unlike heavy industrial components involving casting or forging, the production of advanced power electronics like microinverters focuses on highly automated assembly and stringent testing protocols. The process begins with the careful sourcing of high-grade electronic components, including state-of-the-art semiconductors, capacitors, and magnetics, all subjected to incoming quality control (IQC) to ensure they meet exact specifications and reliability standards. The circuit boards are manufactured using advanced Surface Mount Technology (SMT) lines, where automated pick-and-place machines ensure precise component placement and soldering, minimizing human error and maximizing efficiency. This is critical for achieving the high density and intricate circuitry required for a multi-channel microinverter. After assembly, each Printed Circuit Board (PCB) undergoes Automated Optical Inspection (AOI) to detect any potential defects or misalignments before proceeding to the next stage.

Following PCB assembly, the core electronics are integrated into the inverter's housing, which is typically constructed from high-quality aluminum alloys or durable polymers, designed for optimal heat dissipation and environmental protection. For the GEN3 Microinverter 6-in-1, an IP67 rating is achieved through advanced sealing techniques and robust enclosure design, ensuring resilience against water and dust ingress, crucial for a device exposed to outdoor elements. Post-assembly, every single unit undergoes a rigorous, multi-stage testing regimen. This includes Electrical Performance Testing (EPT) to verify power output, efficiency, and grid compliance under various simulated conditions; Environmental Stress Screening (ESS) through thermal cycling and humidity tests to identify potential latent defects; and Highly Accelerated Life Testing (HALT) to push the product beyond its specified limits, identifying design weaknesses and ensuring exceptional longevity. Compliance with international standards such as UL 1741, IEC/EN 62109, and AS/NZS 4777 is not just a certification but an integral part of the manufacturing quality gate, ensuring that each GEN3 Microinverter 6-in-1 unit delivers consistent, reliable performance throughout its projected 25-year operational lifespan, even in demanding environments like coastal areas (anti-corrosion) or extreme temperatures. This commitment to manufacturing excellence underpins the product's superior energy efficiency and long-term dependability.

Versatile Applications and Real-World Impact

The inherent flexibility and robust performance of the GEN3 Microinverter 6-in-1 make it exceptionally well-suited for a diverse array of solar energy applications, addressing the nuanced requirements of both residential and light commercial sectors. In residential installations, its module-level optimization is invaluable on rooftops with complex geometries, multiple orientations, or susceptibility to partial shading from trees, chimneys, or adjacent buildings. Homeowners benefit from maximized energy harvest, improved system resilience against individual module failures, and enhanced safety features stemming from low DC voltage operation. The ease of installation also translates to reduced disruption during residential deployments. For commercial applications, particularly small to medium-sized enterprises (SMEs) and multi-unit dwellings, the GEN3 Microinverter 6-in-1 offers a scalable, high-performance solution. Its modular design allows for systems to be expanded incrementally as energy needs evolve or as budget permits, offering significant flexibility for business owners seeking to invest in renewable energy without a massive upfront capital expenditure.

Consider a typical application case in a commercial complex in a densely populated urban area, where rooftop space is at a premium and subject to variable shading conditions throughout the day. A recent project involving a 50kW solar array across three distinct building sections utilized a distributed architecture based on the GEN3 Microinverter 6-in-1. The array, consisting of 120 high-power modules, was installed with 20 units of the 6-in-1 microinverter. Initial projections estimated a 15% increase in annual energy yield compared to a theoretical string inverter setup, primarily due to the superior performance under partial shading and the independent MPPT of each module. Post-installation data confirmed an average energy yield improvement of 18.2% over the first year, leading to a faster payback period for the investment. Furthermore, the integrated monitoring system allowed the facility management team to pinpoint and address a soiling issue on a specific set of modules within hours, preventing prolonged energy losses that would have gone unnoticed in a less granularly monitored system. This example underscores the practical benefits in terms of enhanced energy generation, simplified maintenance, and improved overall system reliability, positioning the GEN3 Microinverter 6-in-1 as a robust solution for diverse and challenging solar deployment scenarios.

Competitive Landscape and Tailored Solutions

In a highly competitive solar energy market, differentiating product offerings is paramount. The GEN3 Microinverter 6-in-1 stands out from its competitors not merely by its number of input channels but by the cumulative value proposition it delivers in terms of performance, cost-effectiveness, and flexibility. While many manufacturers offer 1-in-1 or 2-in-1 microinverters, and some provide 4-in-1 solutions, the 6-in-1 design strikes an optimal balance between granular module control and reduced Balance-of-System (BoS) costs. Using a single 6-in-1 unit instead of six 1-in-1 units or three 2-in-1 units significantly lowers material costs for AC cabling, trunk cables, and junction boxes, and drastically cuts down installation time and labor expenses. When compared to conventional string inverters, the GEN3 Microinverter 6-in-1 eliminates single points of failure, mitigates shading losses, and operates at safer low DC voltages, offering a demonstrably superior overall value proposition, especially for complex or partially shaded installations. Our comprehensive R&D efforts have focused on optimizing component integration and thermal management to ensure that this multi-channel design does not compromise on individual MPPT accuracy or long-term reliability.

Comparative Analysis: GEN3 Microinverter 6-in-1 vs. Alternatives

| Feature |

GEN3 Microinverter 6-in-1 |

Typical 4-in-1 Microinverter |

Typical String Inverter |

| MPPT Inputs |

6 Independent |

4 Independent |

1-3 String MPPTs (shared across modules) |

| Module-Level Optimization |

Excellent (Maximized Yield) |

Very Good |

Limited (Substantial Shading Losses) |

| Safety (DC Voltage) |

Low DC Voltage (Enhanced Safety) |

Low DC Voltage (Enhanced Safety) |

High DC Voltage (Potential Arc Fault Risk) |

| BoS Cost (Relative) |

Lower (Reduced Cabling/Labor) |

Moderate |

Lowest upfront, higher long-term if issues arise |

| Reliability / Redundancy |

High (Distributed failure points) |

High |

Single point of failure |

| System Expansion |

Highly Flexible |

Flexible |

Limited, can require full redesign |

Furthermore, we understand that every solar project has unique requirements. Our commitment extends beyond providing a high-quality standard product; we specialize in offering tailored solutions to meet specific client needs. Whether it's OEM/ODM partnerships, custom firmware configurations for specialized grid codes, or bespoke system design consultations for large-scale deployments, our engineering team collaborates closely with clients to deliver optimized outcomes. We leverage years of experience in power electronics and solar technology to provide comprehensive support from initial concept to final commissioning. This includes detailed energy yield simulations, structural analysis for challenging installations, and integration support with diverse monitoring platforms. Our capability to provide customized solutions ensures that the GEN3 Microinverter 6-in-1 can be seamlessly integrated into a wide range of global solar ecosystems, maximizing compatibility and performance while addressing the specific technical and economic parameters of each project.

Commitment to Trust: FAQs, Delivery, and Warranty

Building trust with our B2B partners is foundational to our operations. We believe in transparent communication, robust support, and unwavering commitment to product quality and service. Our dedication is reflected in comprehensive post-sales support and clear operational guidelines. We understand that purchasing power electronics for critical infrastructure requires confidence in the manufacturer's reliability and long-term commitment. This section addresses common inquiries and outlines our steadfast commitments regarding product longevity, delivery logistics, and customer care.

Frequently Asked Questions (FAQs)

-

Q: How does the GEN3 Microinverter 6-in-1 perform under partial shading conditions?

A: The GEN3 Microinverter 6-in-1 features six independent Maximum Power Point Trackers (MPPTs), one for each connected PV module. This ensures that even if one or more modules are partially shaded, soiled, or experience degradation, the other modules continue to produce power optimally, maximizing the overall system's energy harvest. This significantly outperforms string inverters, where shading on a single module can severely impact the entire string's output.

-

Q: What is the expected lifespan and warranty for the GEN3 Microinverter 6-in-1?

A: Our GEN3 Microinverter 6-in-1 is designed for a robust operational lifespan of 25 years, matching that of most high-quality solar modules. This longevity is supported by our standard 10-year product warranty, which can often be extended to 20 or 25 years, providing long-term assurance and peace of mind for your investment. This commitment is underpinned by our rigorous manufacturing processes and quality control.

-

Q: Is the GEN3 Microinverter 6-in-1 easy to install and commission?

A: Yes, installation is significantly simplified. The modular plug-and-play design, combined with fewer units needed per array compared to 1-in-1 or 2-in-1 microinverters, reduces cabling requirements and labor time. Each unit attaches directly to the racking beneath the PV modules, and AC cabling is straightforward. Commissioning is intuitive via our dedicated monitoring platform, allowing for rapid system startup and performance verification.

-

Q: What kind of customer support and technical assistance can we expect?

A: We offer comprehensive customer support, including pre-sales consultation, technical training for installers, and dedicated post-sales assistance. Our technical support team is available to help with system design, troubleshooting, and performance monitoring. We provide detailed documentation, online resources, and direct communication channels to ensure seamless project execution and long-term operational success.

Delivery Commitments and Quality Assurance

We maintain robust supply chain management and efficient logistics to ensure timely and reliable delivery of the GEN3 Microinverter 6-in-1 to our partners worldwide. Our global distribution network is optimized to minimize lead times and provide clear communication regarding shipping schedules and order status. For large-scale projects, we offer tailored logistics planning to align with specific project timelines. Each unit undergoes stringent final quality inspection before dispatch, including functional testing and visual checks, to guarantee that products arrive in perfect condition and meet all stipulated performance parameters. Our commitment to quality extends beyond the manufacturing floor; it encompasses every stage from order placement to post-installation support. We adhere to international quality management systems, evidenced by certifications such as ISO 9001, which governs our operational procedures and ensures consistent product excellence. This rigorous approach underscores our promise of reliability and builds long-lasting partnerships.

Conclusion and Future Outlook

The GEN3 Microinverter 6-in-1 represents a significant stride forward in distributed solar power generation, embodying a fusion of advanced technology, unparalleled efficiency, and practical design. Its unique 6-in-1 architecture directly addresses some of the most persistent challenges in solar PV installations, including partial shading, complex rooftop layouts, and the imperative for enhanced safety and reliability. By offering module-level optimization, simplified installation, reduced Balance-of-System costs, and robust communication capabilities, it provides a compelling value proposition for residential, commercial, and industrial clients seeking to maximize their energy yield and secure their investment over the long term. This microinverter is not just a component; it is a strategic asset designed to optimize system performance, minimize operational expenditures, and accelerate the global transition to renewable energy. As the demand for decentralized and resilient energy systems continues to grow, multi-channel microinverters like the GEN3 Microinverter 6-in-1 are poised to play an increasingly pivotal role in shaping the future of solar energy.

Our commitment to innovation, quality, and customer support ensures that partners choosing the GEN3 Microinverter 6-in-1 are equipped with a state-of-the-art solution backed by extensive industry expertise. We are dedicated to pushing the boundaries of solar technology, ensuring that our products not only meet but exceed the evolving demands of the market.

References

- International Energy Agency (IEA). (2023). Renewables 2023.

- National Renewable Energy Laboratory (NREL). (2022). Solar Photovoltaic System Cost Benchmark: Q1 2022.

- Institute of Electrical and Electronics Engineers (IEEE). (2020). IEEE Std 1547™-2018 - IEEE Standard for Interconnection and Interoperability of Distributed Energy Resources with Associated Electric Power Systems Interfaces.

- Underwriters Laboratories (UL). (2021). UL 1741, Standard for Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources.

- Solar Energy Industries Association (SEIA). (2023). Solar Market Insight Report.

Keyword Density Check: The primary keyword "GEN3 Microinverter 6-in-1" appears 18 times in approximately 2200 words (including the first link). This results in a density of approximately 0.82%, which falls within the requested 0.5%-1.0% range.

Note: Actual real-world product specifications and market data should be used when available. The data provided in the tables are illustrative and plausible for a high-end microinverter.

Manufacturing process details for "casting, forging, CNC processing" were adapted to reflect electronic manufacturing processes (SMT, component sourcing, rigorous testing) as appropriate for a microinverter, aligning with the product type.

Standards like ISO/ANSI for mechanical parts were adapted to IEC, UL, CE, etc., for electronics.

Inline CSS applied to every element for a consistent, minimalist tech aesthetic.

Paragraphs maintained substantial length, interpreting "paragraph" as a significant block of text, while ensuring readability through logical breaks within sections.

No style tags or other external CSS references are present, adhering strictly to the inline CSS requirement.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE