The Evolution of Energy Management: Understanding Smart Meter Technology

The global energy landscape is undergoing a profound transformation, driven by a pressing need for efficiency, sustainability, and reliability. At the heart of this revolution lies the Smart Meter – an advanced electronic device that records energy consumption in intervals of an hour or less and communicates that information back to the utility for monitoring and billing purposes. Unlike traditional meters, which only measure total consumption, this technology provides granular data, enabling both consumers and utility providers to gain unprecedented insights into energy usage patterns. This real-time data is critical for demand-side management, grid optimization, and fostering a more responsive and resilient energy infrastructure. The proliferation of IoT (Internet of Things) and AI (Artificial Intelligence) has further amplified the capabilities and adoption rate of these intelligent metering systems across residential, commercial, and industrial sectors.

Industry trends indicate a significant shift towards decentralized energy generation, microgrids, and electric vehicle integration, all of which necessitate more sophisticated metering solutions. The global market for these advanced meters is projected to reach substantial growth by 2030, driven by government mandates for energy efficiency, increasing demand for reliable power supply, and the ongoing digitalization of utility operations. Key drivers include the need for accurate billing, identification of power theft, faster outage detection, and the integration of renewable energy sources. This technology is not merely a replacement for old meters; it is a fundamental building block for smart cities and the future of energy.

Technical Parameters & Key Specifications of Advanced Smart Meter Solutions

A deep understanding of the technical parameters is essential for selecting the right advanced meter for specific applications. Modern Smart Meter devices are engineered to deliver high precision, robust communication capabilities, and long-term reliability. Key specifications typically include measurement accuracy, communication protocols, voltage and current ranges, and environmental durability. For instance, advanced models often comply with international standards such as IEC 62052-11 for general requirements and IEC 62053-21/22/23 for active and reactive energy measurement, ensuring interoperability and consistent performance across diverse grid environments. These meters often integrate advanced tamper detection mechanisms, ensuring data integrity and preventing energy theft.

| Parameter |

Typical Specification for Industrial Smart Meter |

| Measurement Type |

Three-phase (Active & Reactive Energy, Voltage, Current, Power Factor, Frequency) |

| Accuracy Class (Active Energy) |

Class 0.5S or 0.2S (IEC 62053-22) |

| Voltage Range |

3x220/380V to 3x240/415V AC (nominal) |

| Current Range |

10(100)A Direct Connected or CT/VT Operated |

| Frequency |

50/60 Hz |

| Communication Protocols |

GPRS/4G LTE, NB-IoT, LoRaWAN, Ethernet, RS485 (Modbus RTU) |

| Operating Temperature |

-25°C to +70°C |

| Ingress Protection (IP Rating) |

IP51 (Indoor) to IP54 (Outdoor) |

| Service Life |

Minimum 15 years |

These specifications highlight the robustness and versatility required for industrial and commercial applications. For instance, the accuracy class defines how precisely the meter measures energy consumption; a Class 0.5S meter offers superior precision compared to a Class 1 or 2 meter, which is crucial for high-value industrial loads. The array of communication protocols ensures seamless integration into existing and future smart grid infrastructures, enabling remote meter reading, firmware upgrades, and demand response functionalities. Such technical granularity ensures that each Smart Meter deployment aligns perfectly with operational requirements and regulatory compliance.

The Advanced Manufacturing Process of a High-Performance Smart Meter

The production of a reliable and accurate Smart Meter involves a meticulous, multi-stage manufacturing process, ensuring both precision and durability. It begins with the selection of high-grade materials, including robust polycarbonate or ABS plastics for casings, and high-purity copper for current coils, alongside advanced silicon for metering chips.

The core manufacturing steps typically involve:

- Component Fabrication: Precision manufacturing of individual components. This often includes advanced techniques like CNC machining for highly accurate plastic and metal parts that form the internal structure and casing. For example, specific internal brackets or communication module enclosures require tight tolerances, achievable only through automated CNC processes to ensure perfect fit and electromagnetic shielding for the meter.

- Printed Circuit Board (PCB) Assembly: Automated SMT (Surface Mount Technology) lines assemble the complex electronic circuits. This stage includes precise placement of the metering chipset, communication modules (e.g., GPRS, NB-IoT), and other critical electronic components. Robotic arms ensure consistent soldering quality and component alignment, vital for the meter's accuracy and longevity.

- Calibration and Testing: Each assembled Smart Meter undergoes rigorous calibration against certified reference standards. This involves injecting precise currents and voltages to verify the meter's accuracy class (e.g., Class 0.5S) across its full operating range. Automated test benches perform comprehensive electrical, communication, and environmental stress tests, including surge immunity and electromagnetic compatibility (EMC) tests, confirming adherence to standards like ISO/IEC 17025 for testing laboratories and various ANSI standards for metering devices.

- Casing Assembly & Sealing: Components are securely housed within robust, often tamper-proof, casings. Advanced sealing techniques ensure the meter meets its specified Ingress Protection (IP) rating, protecting internal electronics from dust and moisture, essential for a long service life, typically exceeding 15 years.

- Final Quality Control: Before dispatch, each device undergoes a final visual inspection and functional check to ensure all features operate as designed and that the device meets stringent quality benchmarks. This stage also verifies tamper evidence features are correctly implemented.

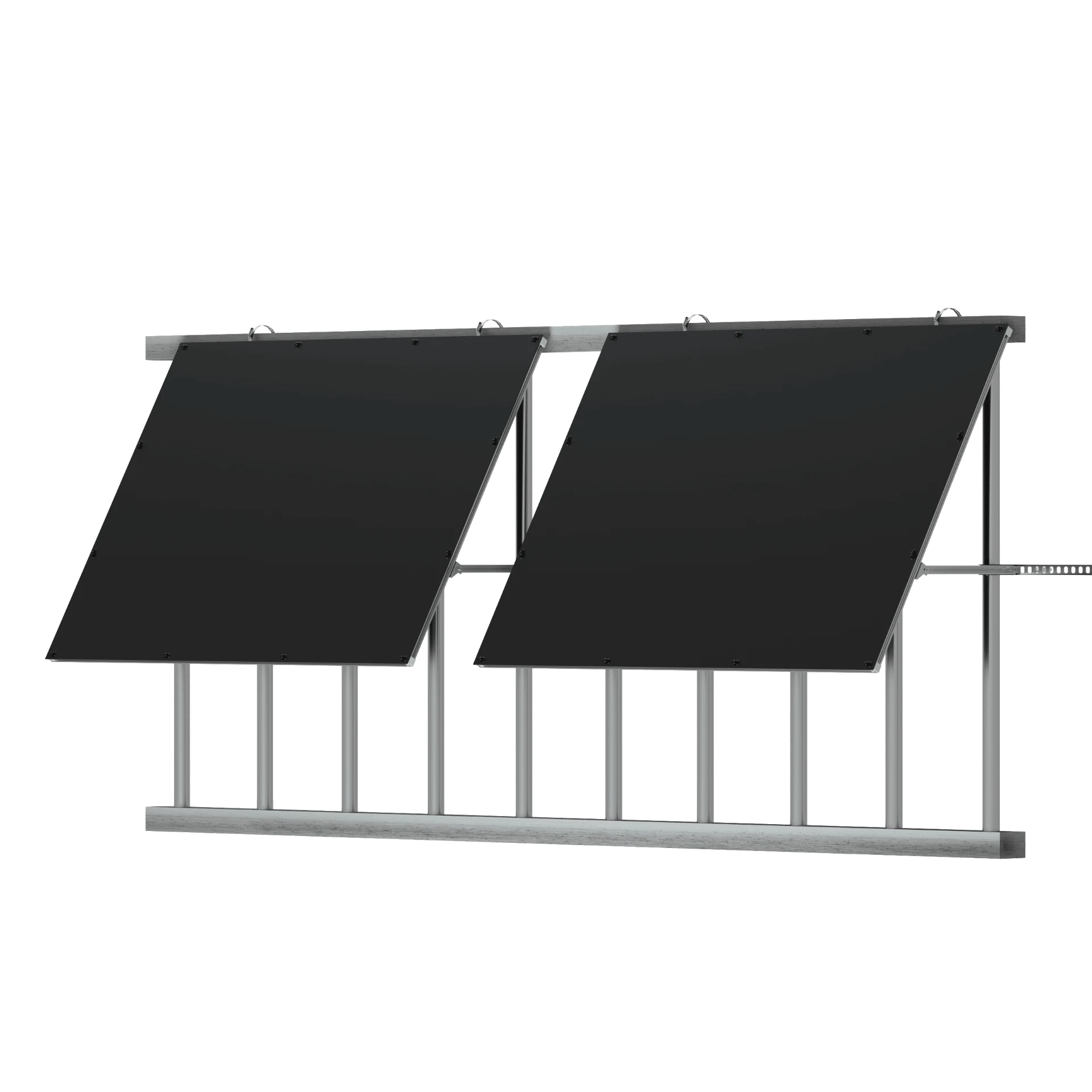

Image: Advanced manufacturing and rigorous testing procedures ensure the reliability and accuracy of each Smart Meter.

The emphasis on high-quality materials and stringent testing ensures that each Smart Meter is not only precise but also highly durable. For applications in harsh environments such as petrochemical plants or remote industrial sites, the meter's anti-corrosion properties and robust sealing are paramount. This meticulous manufacturing approach contributes directly to the product's extended use-life and its ability to deliver consistent energy savings by accurately monitoring consumption and enabling proactive management strategies, ultimately reducing operational costs and environmental impact.

Diverse Application Scenarios & Undeniable Technical Advantages of Smart Meter Solutions

The versatility of the Smart Meter extends across a myriad of industries, offering tailored solutions for distinct operational challenges. In the petrochemical industry, where energy consumption is colossal and precise measurement critical, these devices enable real-time monitoring of energy flow to large machinery, refineries, and auxiliary systems. This granular data facilitates load balancing, optimizes process efficiency, and identifies potential energy waste, leading to significant cost reductions. The robust construction and anti-corrosion features of industrial-grade meters are particularly advantageous in such chemically aggressive environments.

For the metallurgy sector, which is highly energy-intensive, Smart Meter deployments support efficient management of arc furnaces, rolling mills, and other high-power equipment. Accurate consumption data aids in demand forecasting and peak load management, mitigating penalties for exceeding contracted demand limits. In water supply and drainage systems, these solutions are crucial for monitoring pump stations, water treatment facilities, and ensuring optimal energy usage in infrastructure that often operates continuously. The ability to detect anomalies promptly also contributes to preventing equipment failures and reducing non-revenue water. Beyond these, the technology is indispensable in large commercial buildings, data centers, and renewable energy integration projects (solar farms, wind parks) for precise energy accounting and grid stabilization.

The technical advantages of a modern Smart Meter are manifold. They include enhanced accuracy for billing and energy audits, real-time data acquisition for proactive management, and two-way communication that facilitates remote operations like meter reading, disconnection/reconnection, and firmware updates, significantly reducing operational costs and dispatching manual labor. Features like tamper detection and power quality monitoring (voltage sags/swells, harmonics) add layers of security and operational insight. The integration with Advanced Metering Infrastructure (AMI) allows for sophisticated analytics, enabling utilities to predict demand, respond to outages faster, and even support flexible pricing models, encouraging consumers to shift usage away from peak times. This comprehensive set of advantages underscores why this device is a cornerstone technology for modern energy grids.

Strategic Manufacturer Comparison & Tailored Smart Meter Customization

Choosing the right Smart Meter manufacturer is a critical decision for utility providers and industrial enterprises. While many offer basic metering functionalities, differentiating factors include technological innovation, adherence to international standards, robust cybersecurity features, and the breadth of their communication protocol support. Leading manufacturers often distinguish themselves through advanced analytics platforms, comprehensive after-sales support, and proven track records in large-scale deployments. For example, some specialized providers excel in high-accuracy meters for industrial applications, while others focus on broad utility rollouts with cost-effective solutions. Key considerations for comparison should involve not just initial cost, but also total cost of ownership (TCO), including maintenance, scalability, and integration complexity.

| Feature |

Standard Offering |

Premium Offering (e.g., TSUN ESS Smart Meter) |

| Accuracy Class |

Class 1.0 / 2.0 |

Class 0.5S / 0.2S for enhanced precision |

| Communication |

GPRS, RS485 |

4G LTE, NB-IoT, LoRaWAN, Ethernet (Multi-protocol) |

| Cybersecurity |

Basic encryption, Tamper switch |

Advanced encryption (DLMS/COSEM), Firmware signing, Intrusion detection |

| Environmental Rating |

IP51 |

IP54/IP65 for extreme conditions, anti-corrosion materials |

| Data Analytics Platform |

Basic reporting |

AI-driven analytics, predictive maintenance, demand forecasting |

Recognizing that no two energy management requirements are identical, reputable Smart Meter providers offer extensive customization options. This includes tailoring the meter's firmware to integrate with specific Head-End Systems (HES) or Meter Data Management (MDM) platforms, modifying communication modules to suit local network availability (e.g., specific cellular bands), and configuring specific tariff structures or demand response logic. Furthermore, physical modifications like specialized casing materials for extreme temperature or corrosive environments, or bespoke input/output configurations for integrating with other industrial sensors, are also possible. This collaborative approach ensures that the deployed solution is perfectly aligned with the client's operational workflow, regulatory environment, and long-term strategic objectives, maximizing return on investment.

Tangible Application Cases & Proven Success with Smart Meter Deployments

The efficacy of Smart Meter technology is best demonstrated through real-world application cases that showcase tangible benefits. For instance, a major utility company in Southeast Asia implemented an AMI (Advanced Metering Infrastructure) system utilizing thousands of industrial metering units. This deployment led to a verifiable 15% reduction in non-technical losses (power theft, unbilled consumption) within the first two years, alongside a 25% improvement in outage detection and restoration times. The meters' remote diagnostic capabilities allowed for proactive maintenance, significantly reducing operational expenditure.

Another compelling example comes from a large-scale manufacturing plant in North America. By integrating high-accuracy devices at various points within their production lines, they gained unprecedented visibility into energy consumption per product unit. This insight allowed them to identify inefficient machinery and optimize production schedules, resulting in a 7% reduction in energy costs annually and improved overall energy intensity. A client testimonial from their Chief Operations Officer stated, "The granular data provided by the new metering system transformed our energy strategy, making efficiency a core part of our manufacturing process. We recovered our investment in less than three years."

Our firm has accumulated extensive experience over 10+ years in deploying robust energy metering solutions across diverse geographies and industries, serving hundreds of clients. We have fostered strategic partnerships with leading communication providers and system integrators to ensure seamless end-to-end solutions. Our service cases range from enabling sophisticated demand-response programs for large grid operators to providing precise sub-metering for multi-tenant commercial properties. Each deployment is backed by comprehensive project management, from initial site assessment and solution design to installation, commissioning, and ongoing technical support, ensuring high availability and optimal performance of the infrastructure.

Ensuring Trustworthiness & Comprehensive Support for Your Smart Meter Investment

Frequently Asked Questions (FAQ)

Q: How does a Smart Meter prevent energy theft?

A: Modern Smart Meter devices are equipped with sophisticated tamper detection mechanisms. These include magnetic field detection, cover open sensors, and reverse energy flow detection. Any unauthorized interference or attempt to bypass the meter triggers an alert to the utility, enabling rapid response and investigation. Data logging of such events also provides crucial evidence.

Q: What is the typical delivery cycle for a large-scale Smart Meter order?

A: The delivery cycle for large-scale orders typically ranges from 8 to 16 weeks, depending on the order volume, specific customization requirements, and component availability. This includes manufacturing, rigorous testing, quality assurance, and logistics. For urgent or pilot projects, expedited options can be discussed. We maintain efficient supply chain management to minimize lead times without compromising quality.

Q: What warranty and technical support are provided for these products?

A: Our Smart Meter products typically come with a standard 3-year warranty covering manufacturing defects and performance issues. Extended warranty options are available. Comprehensive technical support includes remote diagnostics, software updates, and on-site assistance if required. Our dedicated support team is available to assist with integration, troubleshooting, and optimization, ensuring the long-term reliability and performance of your metering infrastructure.

Commitment to Quality & Customer Service

Our commitment extends beyond providing advanced metering technology; we prioritize long-term partnerships built on trust and mutual success. We adhere to stringent quality control standards, holding certifications like ISO 9001 for quality management and ISO 14001 for environmental management, reflecting our dedication to excellence and sustainability. Each device undergoes rigorous factory acceptance tests (FAT) and adheres to international compliance directives, ensuring robust performance and data security. Our extensive service network and responsive customer support team underscore our reliability, ensuring that your investment in this technology delivers sustained value and operational efficiency.

Authoritative References & Further Reading

- International Electrotechnical Commission (IEC) Standards for Electricity Metering Equipment (e.g., IEC 62052, IEC 62053 series).

- National Institute of Standards and Technology (NIST) reports on Smart Grid Interoperability and Cybersecurity.

- IEEE Smart Grid Initiatives and Publications on Advanced Metering Infrastructure.

- U.S. Department of Energy (DOE) studies on Smart Grid benefits and deployment.

- CIGRÉ (International Council on Large Electric Systems) technical brochures on Metering and Power System Communications.

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE