The global energy landscape is rapidly evolving, driven by an urgent need for sustainable and efficient power generation. Amidst this transformation, solar photovoltaic (PV) systems have emerged as a dominant force, with continuous innovation pushing the boundaries of what's possible. One such pivotal advancement is the smart micro inverter, a technology revolutionizing distributed solar energy. Unlike traditional string inverters, a smart micro inverter optimizes power conversion at the individual solar panel level, enhancing overall system performance, safety, and monitoring capabilities. This shift signifies a move towards more intelligent, resilient, and user-friendly solar solutions, directly addressing challenges like shading, panel mismatch, and complex system troubleshooting. The market for microinverter solar solutions is projected to grow significantly, with reports indicating a compound annual growth rate (CAGR) of over 15% for microinverters in the coming decade, driven by increasing residential and commercial solar installations and the demand for higher efficiency and safety standards.

Industry Trends and Technological Evolution of Microinverters

The solar industry is witnessing profound shifts, from utility-scale farms to hyper-localized, distributed generation. This decentralization necessitates intelligent grid integration and optimized power electronics. Here's how the smart micro inverter fits into these trends:

- Distributed Energy Resources (DERs) Integration: As more homes and businesses generate their own power, the need for sophisticated control and monitoring at the individual module level becomes critical. The smart micro inverter enables seamless integration into the grid, supporting demand-side management and grid stability.

- Internet of Things (IoT) and AI Integration: Modern pv microinverter systems leverage IoT for real-time data collection from each panel. This data, when analyzed by AI algorithms, can predict potential issues, optimize energy harvest based on weather patterns, and even facilitate predictive maintenance. This intelligent monitoring is a hallmark of the smart micro inverter, offering unprecedented visibility into system performance.

- Enhanced Safety Standards: Regulations like NEC 2020 (National Electrical Code) are pushing for rapid shutdown capabilities at the module level. Smart micro inverter designs inherently meet these requirements by converting DC to AC at the panel, significantly reducing high-voltage DC risks on rooftops, enhancing fire safety for first responders and homeowners.

- Modularity and Scalability: The modular nature of microinverter solar kit systems means that installations can start small and expand easily, one panel at a time, without redesigning the entire electrical architecture. This flexibility is appealing for evolving energy needs.

- Grid Services and Resilience: Advanced microinverter models are now capable of providing grid support services, such as reactive power compensation and frequency regulation, contributing to a more stable and resilient electrical grid, especially in areas with high solar penetration.

The evolution from basic microinverter technology to the smart micro inverter represents a leap forward in efficiency, reliability, and grid interaction, paving the way for a more decentralized and intelligent energy future.

Technical Parameters and Performance Deep Dive

Understanding the core technical parameters of a smart micro inverter is crucial for appreciating its capabilities and advantages. These devices are engineered for maximum power point tracking (MPPT) at each panel, ensuring optimal energy harvest regardless of individual panel performance variations.

Key Parameters of a Smart Micro Inverter:

- Maximum Continuous Output Power: Typically ranging from 300W to 2000W+ for single or multi-panel units. For the 1-in-1 Microinverter, it's optimized for individual panel outputs.

- MPPT Voltage Range: The voltage window within which the inverter can efficiently track the maximum power point of the solar module. A wider range ensures compatibility with various panel types and better performance under varying light conditions.

- Maximum Input DC Voltage: The highest DC voltage the inverter can safely handle from the solar panel, typically around 60V for most microinverters.

- Peak Efficiency: The maximum efficiency achieved under ideal operating conditions, often exceeding 97.5% for high-quality smart micro inverter models.

- Weighted Efficiency (CEC or Euro Efficiency): A more realistic measure of efficiency across different power levels, reflecting real-world performance. Values above 96.5% are considered excellent.

- Communication Protocol: How the inverter communicates with the monitoring gateway and the grid. Common protocols include PLC (Power Line Communication), ZigBee, Wi-Fi, or proprietary RF solutions. Our 1-in-1 Microinverter often leverages robust wireless communication for seamless monitoring.

- Operating Temperature Range: The ambient temperature range within which the inverter can operate reliably, usually -40°C to +65°C, indicating robust design for outdoor environments.

- Enclosure Rating: IP67 or IP68 is standard for outdoor-rated pv microinverter devices, signifying complete protection against dust ingress and immersion in water.

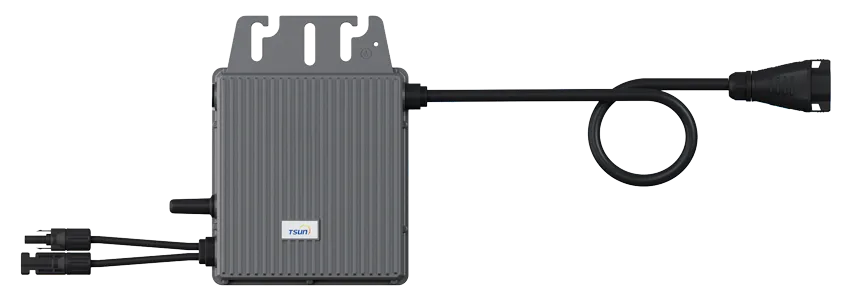

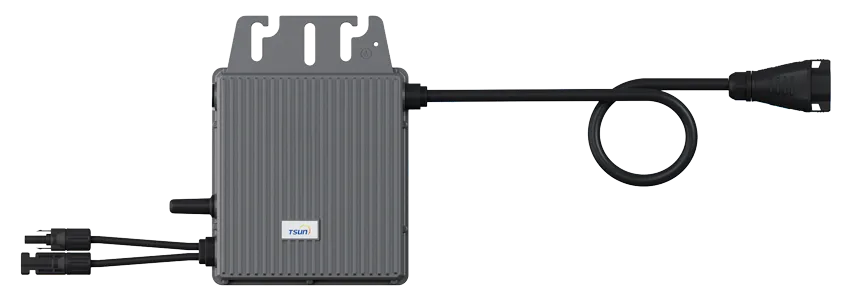

To illustrate, let's consider the specifications relevant to a high-performance smart micro inverter like the TSUN 1-in-1 Microinverter (Product Name: 1-in-1 Microinverter, Product URL: https://www.tsun-ess.com/1-in-1-trunk-microinverter.html). This device exemplifies the cutting edge of microinverter solar technology, designed for maximum efficiency and robust performance.

Smart Micro Inverter Key Performance Parameters (Example)

| Parameter |

Typical Smart Micro Inverter Range |

TSUN 1-in-1 Microinverter (Illustrative) |

Significance |

| Max Output Power |

300W - 2000W+ (per unit) |

Up to 600W (optimized for single panels) |

Determines the compatible panel size and power output. |

| Peak Efficiency |

97.5% - 98.5% |

>97.8% |

Higher efficiency means more AC power from DC input. |

| CEC Weighted Efficiency |

96.5% - 97.5% |

>97.2% |

Real-world efficiency across varying light conditions. |

| MPPT Voltage Range |

20V - 60V |

25V - 55V |

Compatibility with diverse PV module types, optimal harvest. |

| Max Input DC Voltage |

60V |

60V |

Safety limit for connected PV modules. |

| Operating Temperature |

-40°C to +65°C |

-40°C to +65°C |

Ensures reliability in extreme weather. |

| Enclosure Rating |

IP67 / IP68 |

IP67 |

Protection against dust and water immersion, crucial for outdoor use. |

| Communication |

Wi-Fi, Zigbee, PLC |

Integrated Wi-Fi / Proprietary RF |

Enables monitoring and remote control. |

| Warranty Period |

10-25 years |

25 years |

Indicates expected lifespan and manufacturer confidence. |

These parameters underscore the robust engineering behind modern pv microinverter technology, designed to deliver consistent, high-yield performance over decades.

The Craftsmanship and Manufacturing Excellence of a Smart Micro Inverter

The reliability and longevity of a smart micro inverter are not just about its specifications, but also about the meticulous manufacturing processes, choice of materials, and stringent quality control standards applied during its production. The TSUN 1-in-1 Microinverter, for instance, embodies a commitment to high-quality engineering.

Manufacturing Process of a Smart Micro Inverter:

The journey from raw materials to a fully functional smart micro inverter is a complex one, involving precision engineering and advanced automation. While a visual flowchart or video isn't directly embeddable in this text format, the process can be described as follows:

- Component Sourcing and Inspection: High-grade electronic components (capacitors, MOSFETs, microcontrollers, transformers) are sourced from reputable suppliers. Each batch undergoes rigorous incoming quality control (IQC) to ensure adherence to electrical and material specifications. This includes testing for ESD (Electrostatic Discharge) sensitivity and thermal characteristics.

- Printed Circuit Board (PCB) Assembly:

- SMT (Surface Mount Technology): Automated machines precisely place tiny electronic components onto the PCBs. High-speed pick-and-place robots ensure accuracy and consistency.

- Reflow Soldering: The populated PCBs pass through reflow ovens, where solder paste melts and forms secure electrical connections. Temperature profiles are strictly controlled to prevent component damage.

- AOI (Automated Optical Inspection): After soldering, PCBs undergo automated optical inspection to detect any defects like missing components, incorrect polarity, or solder bridges.

- Conformal Coating Application: Key electronic circuits are coated with a protective polymer film. This crucial step safeguards against moisture, dust, chemical contaminants, and temperature extremes, significantly extending the lifespan of the smart micro inverter in harsh outdoor environments. This process is critical for achieving IP67 ratings.

- Housing Fabrication (CNC Machining & Die Casting):

- Material Selection: High-quality, corrosion-resistant aluminum alloys are typically used for the enclosure. These materials offer excellent heat dissipation properties and durability.

- CNC Machining: Precision CNC machines are used to mill and shape the aluminum heat sink components, ensuring optimal thermal pathways and tight tolerances for sealing.

- Die Casting/Forging (for certain parts): Some parts of the enclosure might be die-cast for strength and intricate shapes, followed by precision machining for critical interfaces.

- Final Assembly: The coated PCBs are integrated into the robust aluminum housing. Gaskets and seals are meticulously placed to ensure the IP67 ingress protection rating. All connections, including AC and DC cables, are secured.

- Electrical Testing and Calibration: Each assembled pv microinverter undergoes comprehensive electrical testing:

- Functional Testing: Verifying all electrical circuits are operating correctly.

- Burn-in Testing: Operating the inverters under full load and elevated temperatures for extended periods (e.g., 24-48 hours) to screen out early failures and ensure long-term reliability. This simulates real-world stress.

- Performance Calibration: Fine-tuning the MPPT algorithms and output parameters to achieve optimal efficiency.

- Certification and Quality Control:

- Standards Adherence: Manufacturing processes are certified under international quality management systems like ISO 9001:2015. Environmental management is guided by ISO 14001.

- Product Certifications: Products are tested and certified by independent laboratories to meet global safety and performance standards such as UL 1741, CE, TUV, VDE, and EN 50549. These certifications are critical for market acceptance and homeowner trust.

- End-of-Line Inspection: Final visual inspection and packaging.

Product Material & Craftsmanship Highlights:

- High-Grade Aluminum Alloy Enclosure: Provides superior heat dissipation for thermal management, crucial for electronic longevity, and excellent corrosion resistance, especially important for outdoor installations near coastal areas or in humid climates. The CNC machining ensures precise fitting and sealing.

- Industrial-Grade Electronic Components: Selection of components with high temperature ratings and long lifespans (e.g., solid-state capacitors rated for 105°C and 10,000+ hours) ensures reliability over decades.

- Automated Production Lines: Minimizes human error and ensures consistency, leading to higher product quality and lower defect rates.

- IP67 Rated Design: Achieved through precision-machined housing, high-quality silicone gaskets, and robust cable glands, guaranteeing complete protection against dust and temporary water immersion (up to 1 meter for 30 minutes). This is vital for outdoor electrical equipment.

- Lifespan and Applicable Industries: A typical smart micro inverter is designed for a lifespan of 25 years, aligning with or exceeding the warranty period of most solar panels. While not directly for petrochemical or metallurgy, their rugged design (corrosion resistance, high temperature tolerance) makes them suitable for residential, commercial, and even some industrial rooftops where environmental conditions can be challenging. The focus is on energy generation for various facilities.

- Advantages in Application: For solar applications, the advanced manufacturing ensures:

- Energy Savings: Maximized through individual MPPT and high conversion efficiency.

- Corrosion Protection: The robust, sealed aluminum housing protects internal electronics from environmental degradation, ensuring long-term performance even in harsh weather.

- Enhanced Safety: Reduced high-voltage DC, rapid shutdown compliance, and inherent arc-fault protection, directly benefiting end-users and installation personnel.

Application Scenarios of Smart Micro Inverters

The versatility and inherent advantages of the smart micro inverter make it ideal for a wide array of solar PV applications, from small residential systems to complex commercial installations and specialized projects.

- Residential Solar Installations: This is arguably the largest market segment for microinverter solar kit systems. Homeowners benefit from:

- Shade Mitigation: If one panel is shaded (e.g., by a chimney or tree), only that panel's output is affected, not the entire string. This is a significant advantage over string inverters.

- Module-Level Monitoring: Homeowners can track the performance of each individual panel through a user-friendly app or web portal, easily identifying underperforming modules.

- Enhanced Safety: Low voltage DC on the roof reduces fire hazards and simplifies electrical work.

- Scalability: Easily add more panels to an existing system as energy needs grow.

- Commercial Rooftop Solar: Businesses with complex roof layouts, varying panel orientations, or potential for partial shading (HVAC units, skylights) find smart micro inverter systems highly advantageous. The modularity allows for optimal energy harvest across the entire array, and the robust monitoring capabilities are crucial for operations and maintenance (O&M) teams.

- Small Commercial and Balcony Solar Kits: For smaller businesses or urban dwellers, compact microinverter solar kit solutions are gaining traction. These kits, often utilizing 1-in-1 or 2-in-1 microinverters, provide an accessible entry point to solar energy without requiring extensive roof space or complex electrical installations.

- Complex and Non-Standard Installations: Buildings with multiple roof facets, different panel orientations, or specific architectural constraints benefit immensely from module-level optimization. A smart micro inverter can maximize energy production even when panels face different directions or are installed at varying tilts.

- Retrofitting Existing Systems: While often requiring a full inverter replacement, some older string inverter systems can be upgraded to a microinverter architecture to gain the benefits of module-level optimization and improved safety.

- Hybrid Systems (Solar + Storage): The inherent intelligence and precise power control of a smart micro inverter makes it highly compatible with battery storage solutions, allowing for efficient DC-coupled or AC-coupled energy storage, enhancing energy independence and resilience.

Technical Advantages of Smart Micro Inverters over Traditional Systems

The "smart" aspect of a smart micro inverter transcends basic power conversion, offering a suite of benefits that address the limitations of conventional string inverter systems.

- Module-Level Power Optimization: This is the paramount advantage. Each smart micro inverter performs MPPT for its specific panel. In a string inverter system, the entire string's output is limited by the weakest or most shaded panel (the "Christmas light effect"). With microinverters, if one panel is underperforming, the others continue to produce at their maximum potential, leading to significantly higher overall energy yield (typically 5-25% more in real-world conditions with shading or panel mismatch).

- Enhanced Safety: Smart micro inverter systems eliminate high-voltage DC current (typically 300-600V+) on rooftops by converting DC to safe AC (e.g., 240V or 208V) at the module level. This dramatically reduces fire risks and simplifies emergency response. They inherently comply with rapid shutdown requirements (NEC 2017 & 2020), which mandate that DC conductors outside the array boundary must be reduced to a safe voltage within seconds of shutdown initiation.

- Superior Reliability and Redundancy: With a string inverter, a single point of failure can bring down the entire system. In a microinverter solar array, if one unit fails, only that specific panel's output is affected, while the rest of the system continues to operate. This distributed architecture improves overall system uptime and energy production.

- Granular Monitoring and Diagnostics: Every smart micro inverter continuously transmits performance data. This allows for precise, module-level monitoring through a web portal or app, enabling rapid identification of issues (e.g., dirty panels, faulty modules, or individual inverter malfunctions). This level of detail is unavailable with string inverters, where identifying a single underperforming panel can be a manual, time-consuming task.

- Scalability and Flexibility: Adding panels to a microinverter solar kit system is straightforward; you simply add another panel and microinverter. There's no need to re-size the central inverter or worry about voltage and current matching, offering unparalleled design flexibility for future expansion.

- Simplified Design and Installation: While requiring more individual connections, the lack of complex string sizing calculations and high-voltage DC wiring simplifies system design for installers. The plug-and-play nature of many microinverter designs reduces installation time and labor costs.

- Longer Warranties: Due to their robust design, lower thermal stress (distributed heat dissipation), and independent operation, smart micro inverter units often come with significantly longer warranties (20-25 years) compared to string inverters (5-12 years), reflecting manufacturer confidence in their longevity.

Smart Micro Inverter Manufacturer Comparison (Conceptual)

The market for microinverter technology is dynamic, with several key players offering innovative solutions. While a direct comparison of specific brands is beyond the scope here, we can highlight the critical factors that differentiate manufacturers and help consumers make informed decisions, ensuring the highest quality pv microinverter for their needs.

Key Comparison Factors:

| Factor |

Traditional Microinverter Focus |

Smart Micro Inverter Manufacturer Focus (e.g., TSUN) |

Implication for Users |

| Efficiency |

Good (96-97%) |

Excellent (>97.5% peak, >97% weighted) |

Higher energy yield, faster ROI. |

| Warranty Period |

10-15 years |

20-25 years |

Longer product lifespan, peace of mind, reduced replacement costs. |

| Communication & Monitoring |

Basic data logging, often requires proprietary gateway. |

Advanced, real-time, module-level data via Wi-Fi/Cloud, AI analytics. |

Granular insights, proactive issue detection, better system management. |

| Grid Interaction Features |

Limited (basic grid-tie) |

Advanced (reactive power support, ride-through, rapid shutdown) |

Better grid stability, compliance with evolving regulations. |

| Build Quality & IP Rating |

Good (IP65/IP66) |

Superior (IP67/IP68, robust materials, high-grade components) |

Durability, reliability in harsh environments, lower failure rates. |

| Certifications |

Basic region-specific (e.g., CE, UL) |

Extensive global certifications (UL, CE, VDE, EN, AS/NZS, etc.) |

Global market access, verified safety and performance. |

| Customer Support & Service |

Standard support |

Comprehensive (technical support, online resources, long-term commitment) |

Reliable assistance, smooth operations. |

| Integration with Storage/EV Charging |

May require separate interfaces. |

Designed for seamless integration with energy storage, EV chargers. |

Future-proof system, holistic energy management. |

TSUN, with its focus on the 1-in-1 Microinverter and similar products, exemplifies the "Smart Micro Inverter Manufacturer" profile, emphasizing high efficiency, robust design, comprehensive monitoring, and long-term reliability. Their commitment to these areas provides a significant competitive edge and a better value proposition for the end-user seeking a reliable smart micro inverter.

Custom Solution Design with Smart Micro Inverters

One of the most compelling aspects of the smart micro inverter architecture is its inherent flexibility, allowing for highly customized solar solutions tailored to specific site conditions and energy requirements. This contrasts sharply with the "one-size-fits-all" approach often imposed by traditional string inverter systems.

Addressing Unique Site Challenges:

- Complex Roof Geometries: Many residential and commercial buildings have roofs with multiple angles, varying orientations (e.g., east, west, south), and numerous obstructions like chimneys, vents, or HVAC units. A smart micro inverter system allows each panel to be placed optimally without negatively impacting others, maximizing energy harvest across the entire array. Installers can design systems that utilize every available square foot of roof space efficiently.

- Partial Shading Scenarios: Shading is a common challenge that can drastically reduce solar output. With a smart micro inverter, only the shaded panel's output is affected. For example, if a tree casts a shadow on just two panels in a 20-panel array, the other 18 continue to produce at full capacity. This resilience is critical for maintaining high performance over time.

- Future Expandability: Clients often start with a smaller system and wish to expand later. Adding panels and accompanying microinverter units is a seamless process, avoiding the need for complex redesigns or costly inverter replacements. This "pay-as-you-grow" model makes solar adoption more accessible and future-proof.

- Module Mismatch Mitigation: Even new solar panels can have slight variations in performance, and over time, some panels may degrade faster than others. A smart micro inverter ensures that each panel operates at its individual peak, negating the negative effects of module mismatch that can plague string systems.

Tailored Energy Solutions:

Manufacturers offering smart micro inverter solutions, like TSUN with its 1-in-1 Microinverter, work closely with installers and clients to provide comprehensive design and support. This includes:

- System Sizing and Optimization: Using advanced simulation software to determine the ideal number of panels and microinverters for a given energy demand and roof configuration, taking into account local climate data and shading analysis.

- Component Selection: Recommending compatible solar panels that pair optimally with the specific pv microinverter model to maximize efficiency and longevity.

- Monitoring System Setup: Assisting in the configuration of the monitoring gateway and cloud-based platform, ensuring clients have easy access to real-time and historical performance data.

- Integration with Energy Storage: Designing systems that seamlessly integrate with battery storage solutions for enhanced self-consumption, backup power, and grid independence.

- Regulatory Compliance: Ensuring the proposed system meets all local electrical codes (e.g., NEC 2020) and utility interconnection requirements, including rapid shutdown and grid-tie standards.

The ability to craft a highly customized, resilient, and expandable solar solution is a major draw for the smart micro inverter, making it a preferred choice for those seeking optimal performance and long-term value.

Real-World Application Cases and Customer Experience

The true measure of a technology's success lies in its practical application and the benefits it delivers to end-users. Smart micro inverter systems have been deployed in countless scenarios, demonstrating tangible advantages for diverse customers. While specific customer names are proprietary, the patterns of positive feedback and enhanced performance are consistent.

Case Study 1: Residential Shading Mitigation

Scenario: A homeowner in a suburban area had a large, south-facing roof ideal for solar, but a mature tree on a neighbor's property caused significant shading on a portion of the array during late mornings. A string inverter system would have seen a substantial reduction in overall output.

Solution: Installation of a 10 kW system using 25 units of smart micro inverter (e.g., TSUN 1-in-1 Microinverter) paired with 400W panels.

Outcome: Module-level MPPT ensured that only the shaded panels experienced a temporary dip in production. The unshaded panels continued to produce at full capacity. Over a year, the system consistently outperformed initial production estimates for a string inverter in the same scenario by 15-20%, directly attributed to the smart micro inverter's ability to isolate shading impacts. The homeowner appreciated the detailed monitoring that showed exactly which panels were affected and when, confirming the system's resilience.

Case Study 2: Commercial Rooftop Optimization

Scenario: A commercial building had a sprawling, flat roof with multiple HVAC units and skylights, creating a fragmented layout. Maximizing solar coverage with a string inverter would have been inefficient due to multiple short strings and potential for module mismatch.

Solution: A 100 kW system leveraging hundreds of pv microinverter units. The modularity allowed panels to be placed around obstructions, and different orientations were used to capture sunlight throughout the day.

Outcome: The system achieved a higher energy density per square foot than a comparable string inverter system. Real-time monitoring provided operations managers with crucial data on energy production, allowing for proactive cleaning schedules for specific sections of the array and quick identification of any underperforming modules, minimizing downtime and maximizing the return on investment. The enhanced safety (low DC voltage) was also a significant factor for the building management.

Case Study 3: Remote Monitoring & Maintenance Efficiency

Scenario: An installer managed multiple small-to-medium residential microinverter solar kit installations across a wide geographical area. Identifying and troubleshooting issues remotely was a challenge with older systems.

Solution: Standardizing new installations with a smart micro inverter system that offers robust cloud-based, module-level monitoring.

Outcome: The installer could remotely diagnose 90% of performance issues without dispatching a technician. For example, they could identify if a panel was dirty, had a loose connection, or if an individual microinverter required attention. This significantly reduced truck rolls, lowered operational costs, and improved customer satisfaction through faster resolution times. The predictive analytics features, fueled by data from the smart micro inverter, also helped schedule preventive maintenance efficiently.

These real-world examples underscore the practical benefits of investing in a smart micro inverter system: higher energy yield, superior reliability, enhanced safety, and unparalleled monitoring capabilities, all contributing to a more efficient and satisfying solar experience.

Trustworthiness and Customer Assurance

Building trust is paramount in the solar industry, particularly for long-term investments like a smart micro inverter system. Manufacturers like TSUN prioritize transparency, robust quality assurance, and comprehensive customer support to ensure confidence.

- Industry Certifications and Compliance: The TSUN 1-in-1 Microinverter, like other leading pv microinverter products, adheres to rigorous international and regional standards. This includes:

- UL Certification (e.g., UL 1741, UL 1741 SA): Essential for the North American market, certifying electrical safety and grid-support functionality.

- CE Mark: Mandatory for products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- VDE-AR-N 4105, EN 50549: German and European grid code compliance, critical for grid stability and reliable interconnection.

- AS/NZS 4777.2: Australian/New Zealand standards for grid connection of energy systems.

- ISO 9001:2015 Certification: Demonstrates adherence to international quality management system standards throughout design, development, production, and service.

- ISO 14001:2015 Certification: Indicates compliance with environmental management system standards.

These certifications are not merely badges; they represent independent verification of the smart micro inverter's quality, safety, and performance, ensuring that products meet the highest industry benchmarks.

- Company Track Record and Authoritative Citations: Established manufacturers in the microinverter solar space often boast years of experience and millions of installed units worldwide. For instance, TSUN, having operated in the renewable energy sector for over a decade, has built a reputation for innovation and reliability. Partnerships with leading solar installers and distributors globally further solidify their market authority. References to market research reports (e.g., from Wood Mackenzie, BloombergNEF, or SEIA) consistently highlight the growing adoption of distributed power electronics like the smart micro inverter.

- Warranty Commitment: A critical aspect of trustworthiness is the product warranty. The TSUN 1-in-1 Microinverter comes with an industry-leading 25-year limited warranty. This long-term commitment directly reflects the manufacturer's confidence in the product's durability and expected lifespan, aligning with that of solar panels. This extensive warranty protects the customer's investment for decades.

- Customer Support and Service: Reliable post-sales support is crucial. This includes:

- Multi-channel Support: Availability via phone, email, and online support portals for technical inquiries and troubleshooting.

- Extensive Documentation: Comprehensive installation manuals, user guides, and troubleshooting FAQs available online.

- Global Service Network: For larger manufacturers, a global presence ensures localized support and faster response times for international customers.

- Delivery Cycle and Supply Chain Reliability: For installers and large projects, predictable delivery times are vital. Reputable smart micro inverter suppliers maintain robust supply chains and efficient logistics to ensure timely product delivery, minimizing project delays. Standard lead times are often communicated transparently, and express shipping options may be available for urgent needs.

By consistently delivering on these aspects, companies selling a smart micro inverter build a strong foundation of trust with their customers, from individual homeowners to large commercial enterprises.

Frequently Asked Questions (FAQs) about Smart Micro Inverters

Q1: What is the main difference between a smart micro inverter and a traditional string inverter?

A smart micro inverter optimizes power at the individual solar panel level, meaning each panel operates independently. A traditional string inverter processes power from a series of panels (a "string"), and the performance of the entire string can be limited by the lowest-performing panel (e.g., due to shading or dirt). Smart micro inverter systems offer module-level monitoring, enhanced safety, and greater resilience to shading and panel mismatch.

Q2: How does a smart micro inverter enhance safety in a solar installation?

Unlike string inverters that carry high-voltage DC (Direct Current) electricity (often 300-600V+) across the rooftop to a central inverter, a smart micro inverter converts DC to low-voltage AC (Alternating Current) directly at each solar panel. This significantly reduces the amount of high-voltage DC present on the roof, mitigating fire risks and making it safer for homeowners and emergency responders. They also inherently meet rapid shutdown requirements.

Q3: What does "module-level MPPT" mean, and why is it important for a pv microinverter?

MPPT stands for Maximum Power Point Tracking. Module-level MPPT means that each smart micro inverter has its own dedicated MPPT circuit for its assigned solar panel. This ensures that every panel produces its absolute maximum power independently, regardless of how other panels in the array are performing. This is crucial because it maximizes overall energy harvest, especially in conditions like partial shading, varying panel orientations, or panel degradation over time.

Q4: What certifications should I look for when purchasing a smart micro inverter?

Key certifications to look for include UL (Underwriters Laboratories) for North America (specifically UL 1741 and UL 1741 SA for grid services), CE Mark for Europe, VDE for Germany, and AS/NZS for Australia/New Zealand. Additionally, ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) certifications for the manufacturer indicate a commitment to quality and responsible production. These certifications guarantee that the microinverter meets stringent safety, performance, and environmental standards.

Q5: What is the typical lifespan and warranty for a smart micro inverter?

A high-quality smart micro inverter is designed for a long operational lifespan, typically 25 years or more, often matching the lifespan of solar panels. This long lifespan is supported by comprehensive warranties, which commonly range from 10 to 25 years. For instance, the TSUN 1-in-1 Microinverter offers a 25-year warranty, reflecting confidence in its durability and reliability.

Q6: Are smart micro inverters compatible with all types of solar panels?

Generally, smart micro inverters are highly versatile and compatible with a wide range of standard crystalline solar panels. However, it's crucial to check the inverter's MPPT voltage range and maximum input current to ensure it matches the specifications of the chosen solar panels for optimal performance. Consulting the product datasheet (like that for the TSUN 1-in-1 Microinverter) is essential.

Q7: How does an IP67 rating benefit a pv microinverter?

An IP67 rating means the microinverter is "ingress protected" against dust and water. The '6' indicates complete protection against dust ingress, and the '7' signifies protection against temporary immersion in water up to 1 meter for 30 minutes. This rating is crucial for outdoor electronic equipment like a smart micro inverter, ensuring it can withstand harsh environmental conditions, including heavy rain, dust storms, and even temporary flooding, thus guaranteeing long-term reliability and performance.

The rise of the smart micro inverter marks a significant milestone in solar energy technology, promising a future of more efficient, safer, and intelligent distributed power generation. From enhancing energy yields through module-level optimization to ensuring unparalleled system safety and providing granular monitoring capabilities, the advantages are clear. As the demand for residential and commercial solar continues to surge, the smart micro inverter is poised to be the cornerstone of resilient and high-performing solar PV systems worldwide. Its robust design, adherence to global standards, and long-term warranties, as exemplified by products like the TSUN 1-in-1 Microinverter, solidify its position as a preferred choice for installers and end-users alike. The ongoing integration of IoT and AI further amplifies its "smart" capabilities, making solar power not just cleaner, but also smarter and more adaptable to the evolving energy landscape.

References and Further Reading:

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

LEARN DETAILS

Downloads

Downloads Video Center

Video Center Report Fault for Repair

Report Fault for Repair FAQS

FAQS Service Network

Service Network Privacy Policy

Privacy Policy Contact us

Contact us Monitoring

Monitoring

LEARN MORE

LEARN MORE